Built-up type secondary battery

A secondary battery and combined technology, which is applied in secondary batteries, secondary battery manufacturing, secondary battery repair/maintenance, etc., can solve problems such as increased space, reduced thermal conductivity, and reduced cooling capacity, and achieves a compact connection structure , form a compact structure, increase the effect of the cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

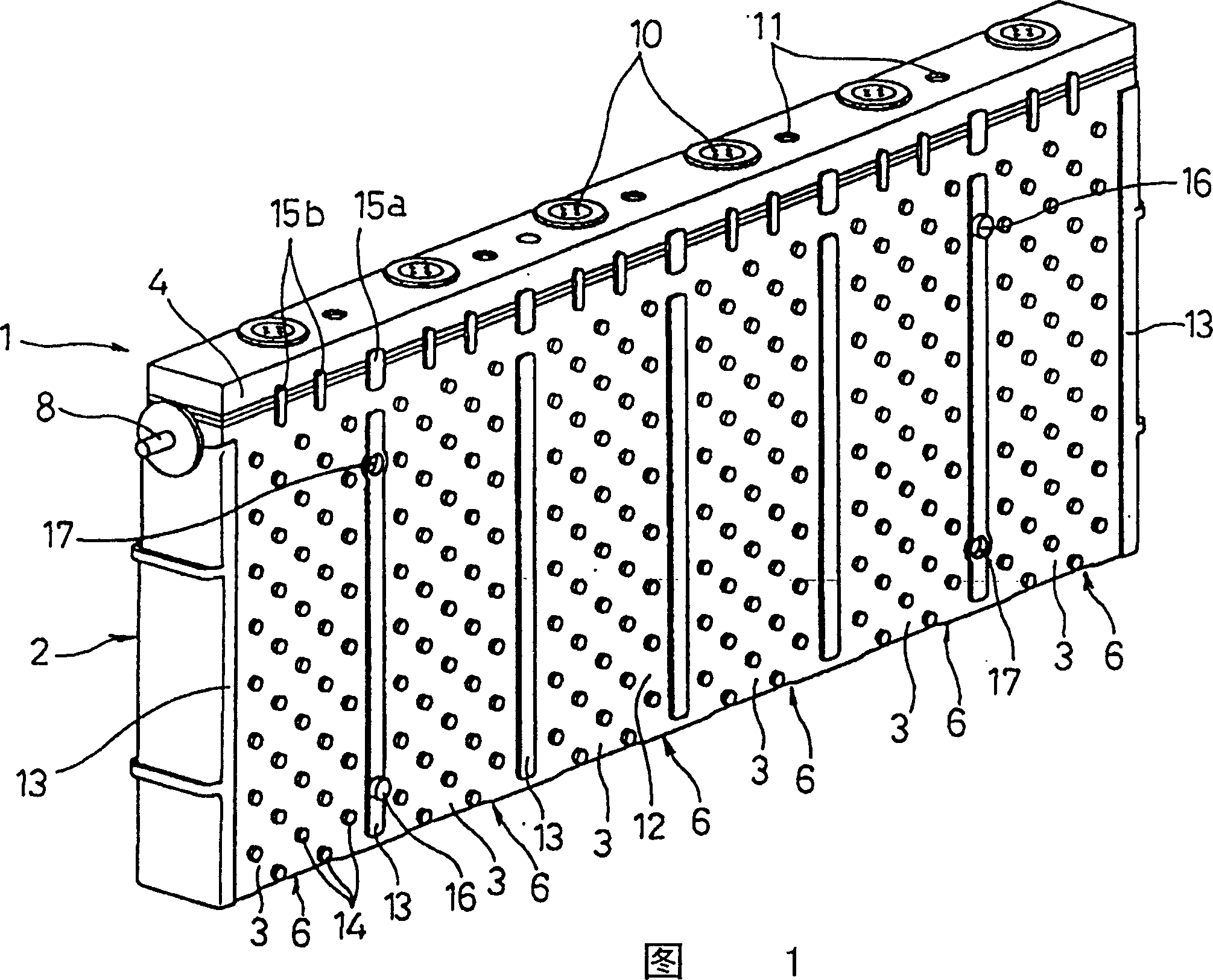

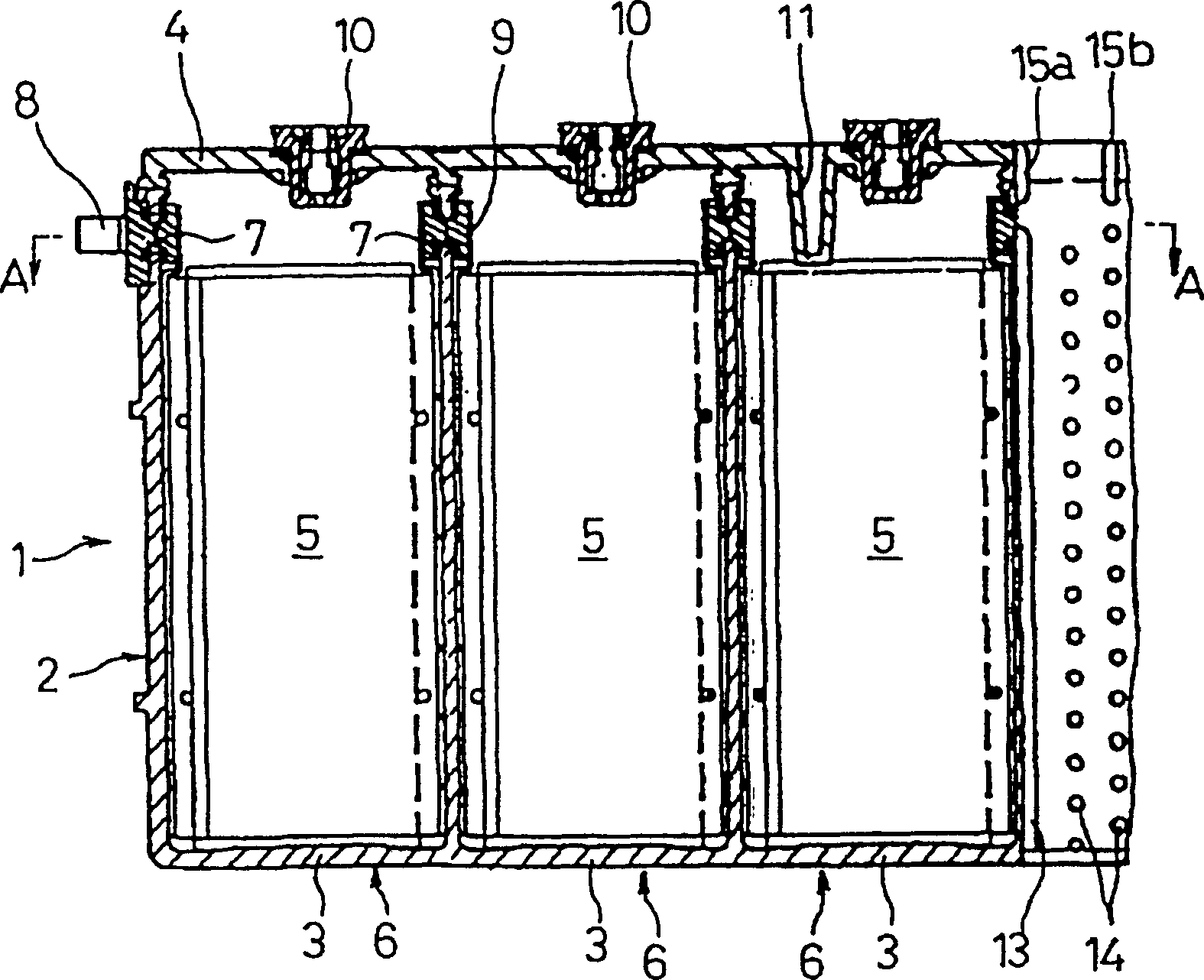

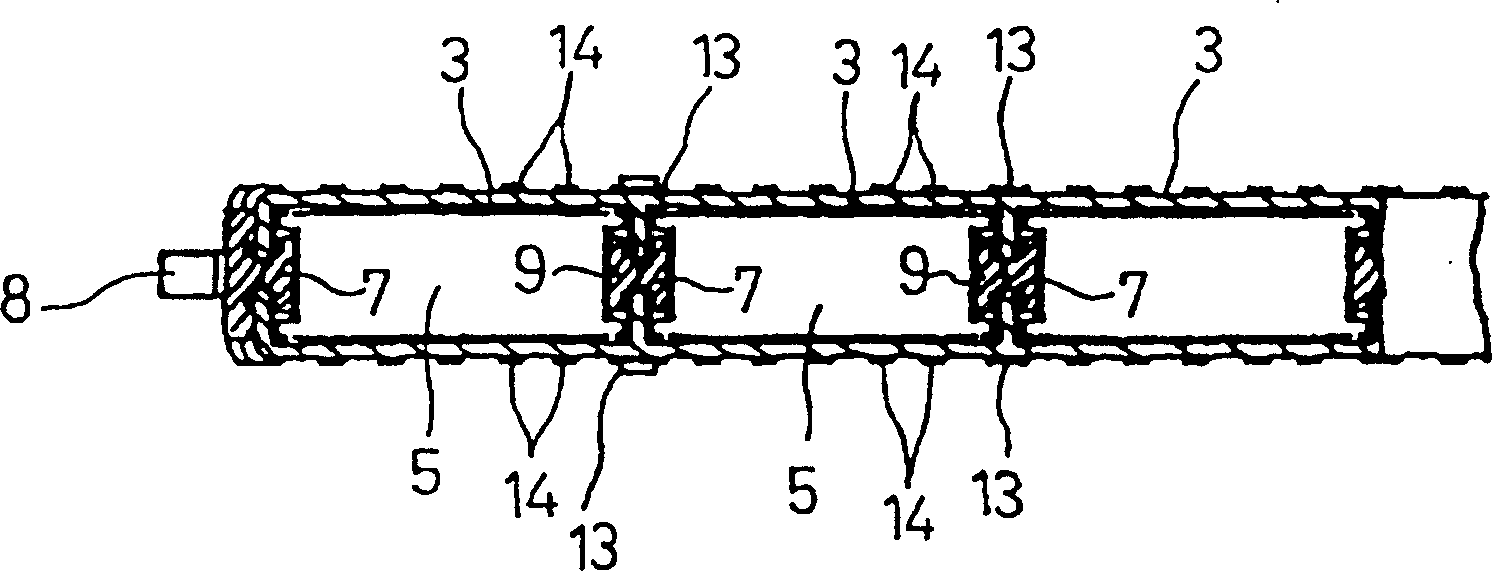

[0025] Refer to Figure 1- Figure 8 , an embodiment of the combined secondary battery of the present invention will be described.

[0026] The combined secondary battery 1 of the present embodiment is a nickel and hydrogen secondary battery suitable for use as a driving source of an electric vehicle, as shown in Fig. 1- image 3 As shown, it is composed of a plurality of cuboid-shaped (six in the illustrated example) battery slots 3 having a narrow narrow side and a wide wide side with an opening on the upper side. , and the upper opening of each battery chamber 3 is integrally closed by an integral cover body 4 .

[0027] In each battery case 3, as will be described in detail later, a plurality of positive plates and negative plates parallel to the broad side of the battery case 3 are stacked in the direction of the narrow side through the separator to form a plate group 5. It is housed in each battery case 3 together with the electrolytic solution to form a single battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com