High temp.-resisting plasma cavity resonator

A technology of plasma and resonant cavity, which is applied in the direction of gaseous chemical plating, metal material coating technology, electrical components, etc., can solve the problems of bad deformation service life of the resonant cavity, short continuous working time, frequent maintenance, etc., to achieve Improved high temperature resistance, increased processing power, and the effect of avoiding slag drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

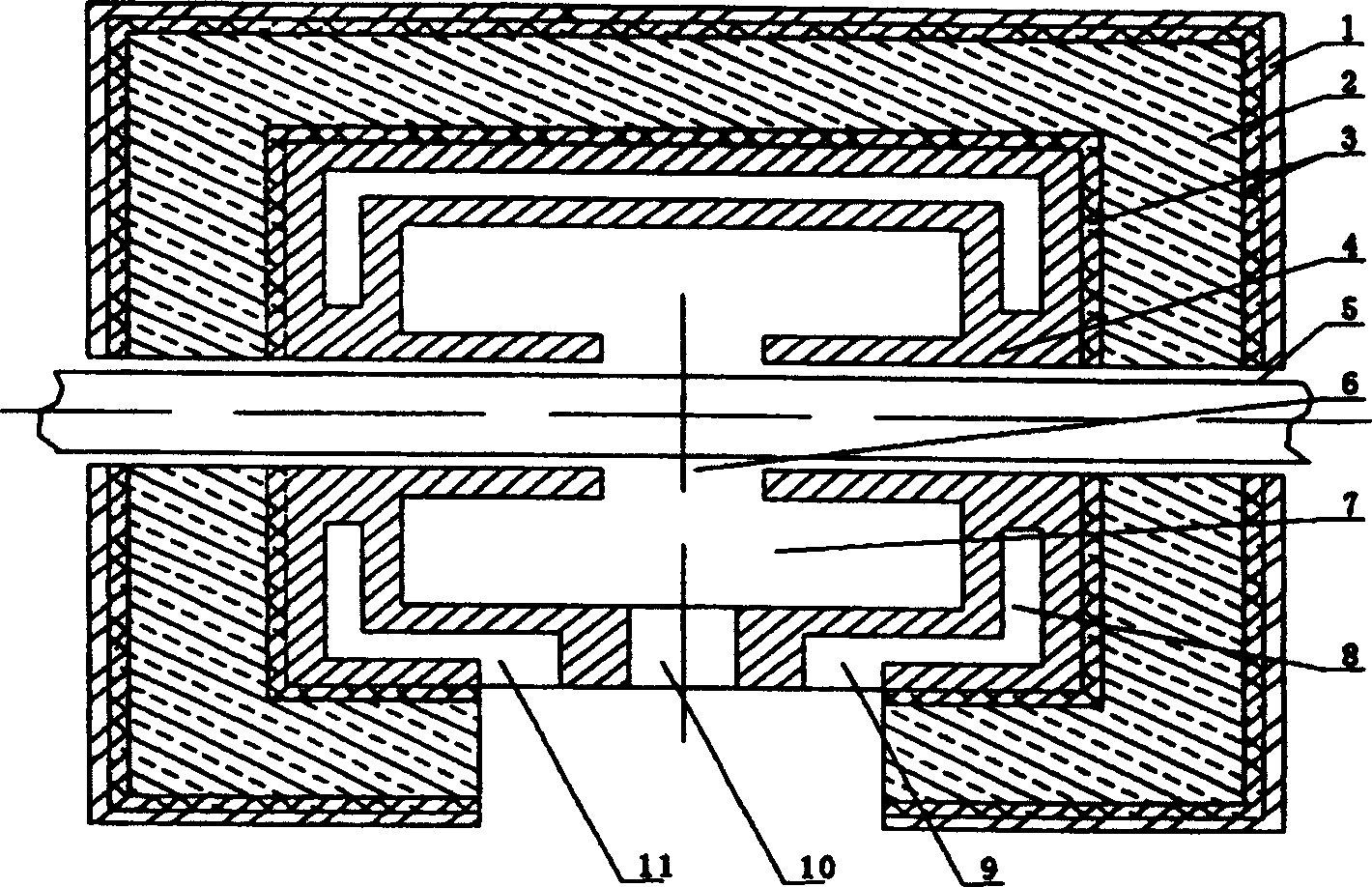

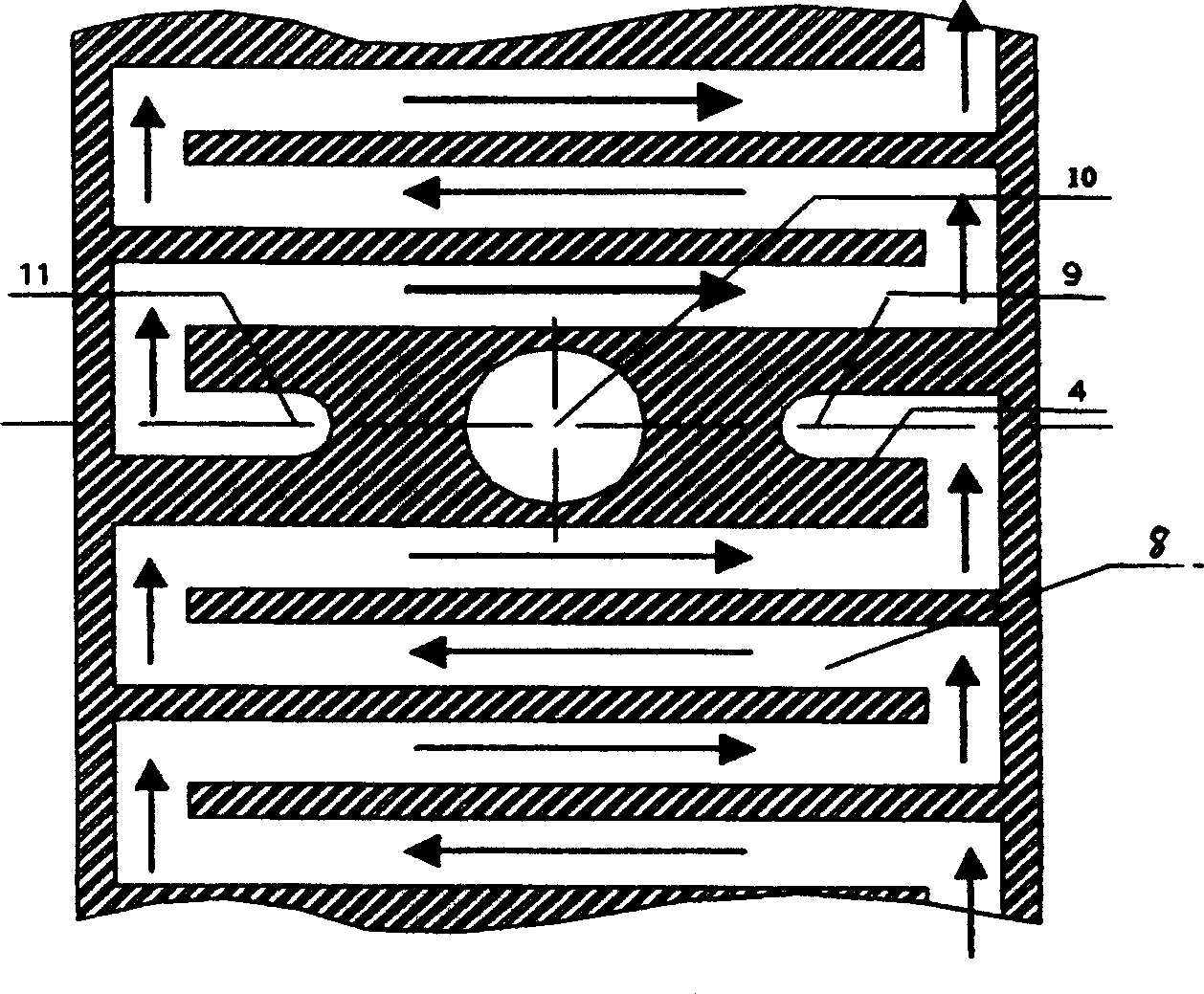

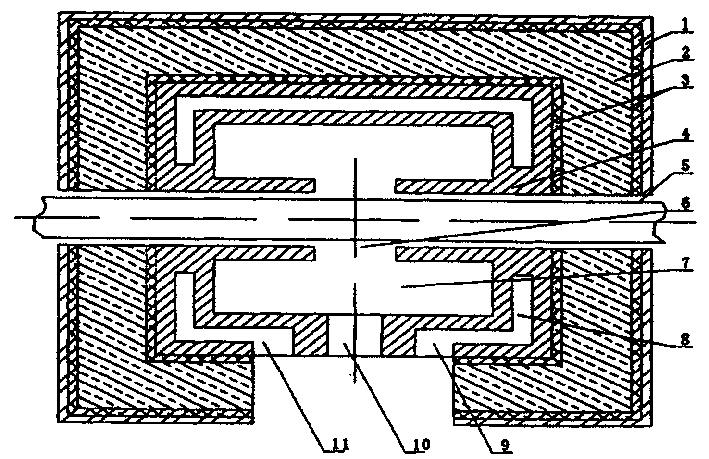

[0011] The embodiments of the present invention are further described below with reference to the accompanying drawings, including a cylindrical resonant cavity shell 4, the resonant cavity shell is made of metal material, and includes an outer cylindrical surface and an inner cylindrical surface, and the middle part is provided with an axial Through hole, a ring-shaped resonant cavity 7 is arranged in the resonant cavity shell, the inner cylindrical surface of the resonant cavity is provided with a power output port 6, and the outer cylindrical surface of the resonant cavity is connected to the power input hole 10, and the power The output hole is generally located in the middle of the resonant cavity shell, and an axial reciprocating circuit cooling water channel 8 is arranged around the periphery and both ends of the resonant cavity shell in the resonant cavity shell, and the cooling water channel at the turning point of the two ends extends inward for a certain distance. , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com