Printed circuit assembly, its mfg. method

A printed circuit assembly, printed circuit board technology, applied in printed circuit manufacturing, printed circuit components, printed circuits, etc., can solve problems such as undesired solder reflow, module failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will now be described with reference to the accompanying drawings, wherein like reference numerals refer to like elements throughout. The terms used in this specification are to be interpreted in their broadest reasonable manner, even if such terms are used in conjunction with descriptions of specific details of certain preferred embodiments of the invention. This is also emphasized below with reference to certain specific terms used herein. In this specification, any term understood by the reader in any restrictive manner shall be so expressly and specifically defined.

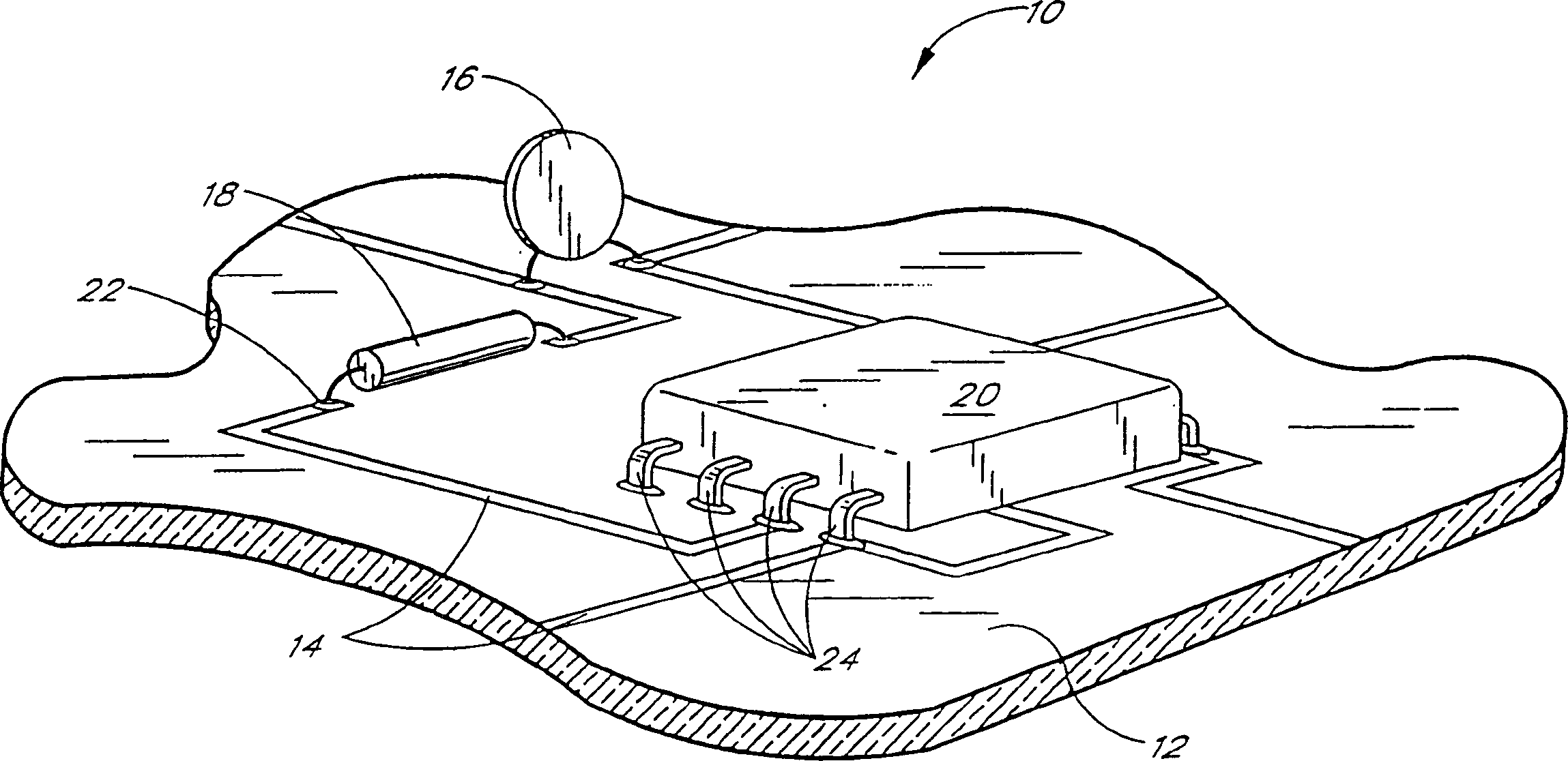

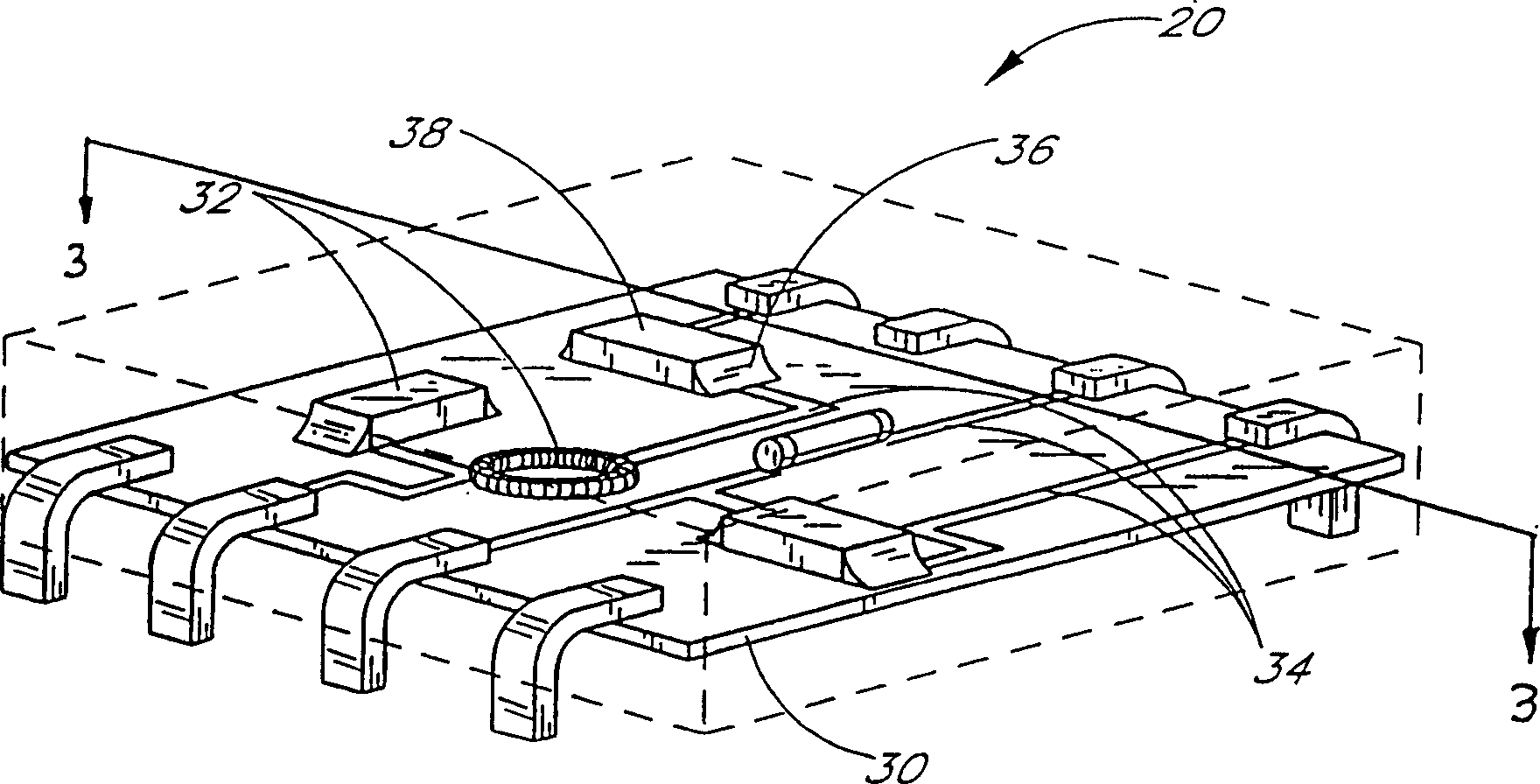

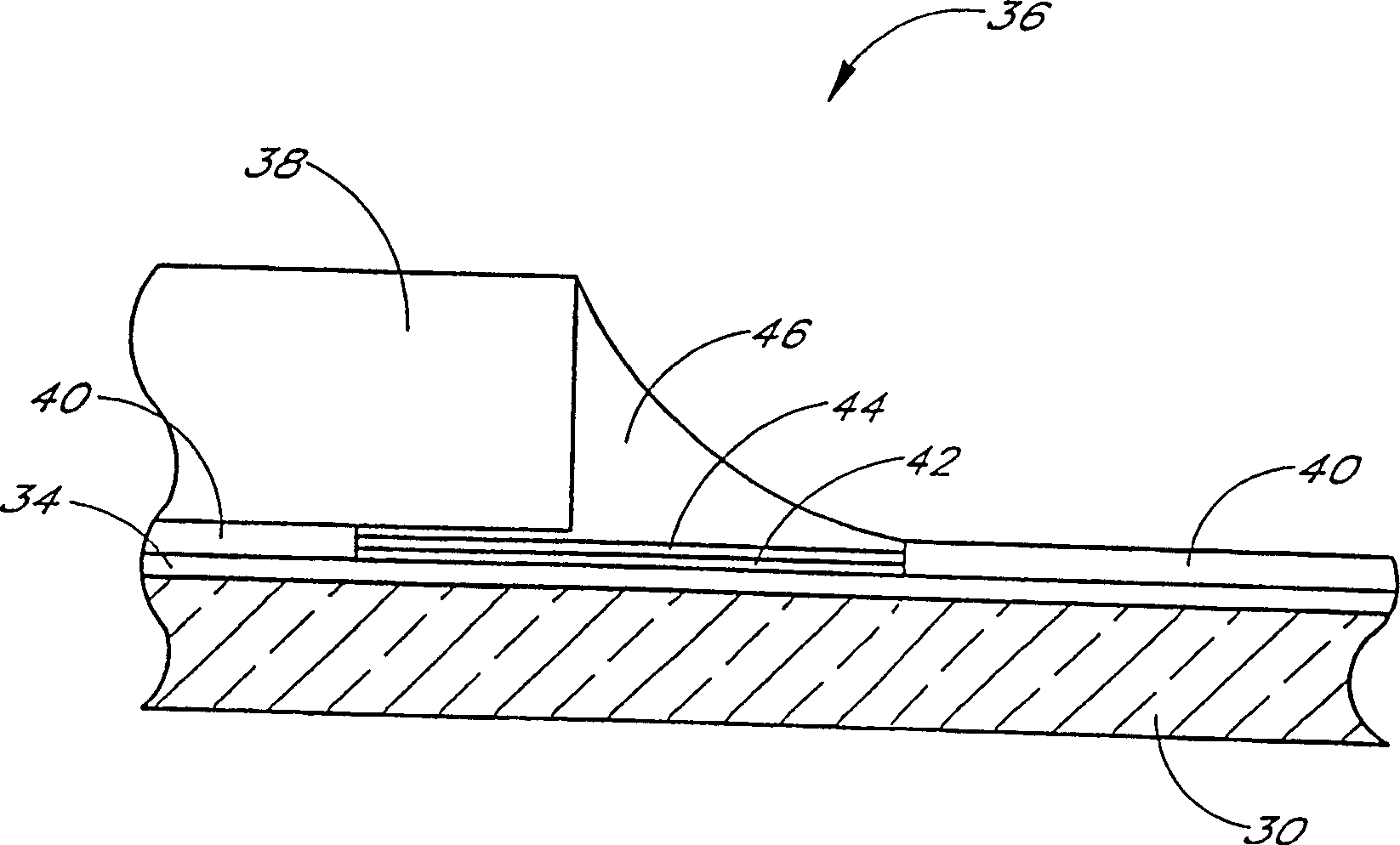

[0018] exist figure 1 , a portion of a printed circuit assembly 10 is shown. The printed circuit assembly 10 includes a printed circuit board 12 made of a dielectric material, which can include a variety of materials and structures known to those skilled in the art. Some known alternatives include laminated paper / phenolic and glass / epoxy constructions. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap