Coating for parper making surface finishing

A coating and topcoating technology, applied in paper coatings, papermaking, textiles and papermaking, etc., can solve the problems of poor ink absorption, increased production cost, reduced whiteness, etc. The effect of fluffy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The present invention is further described and examples are given below.

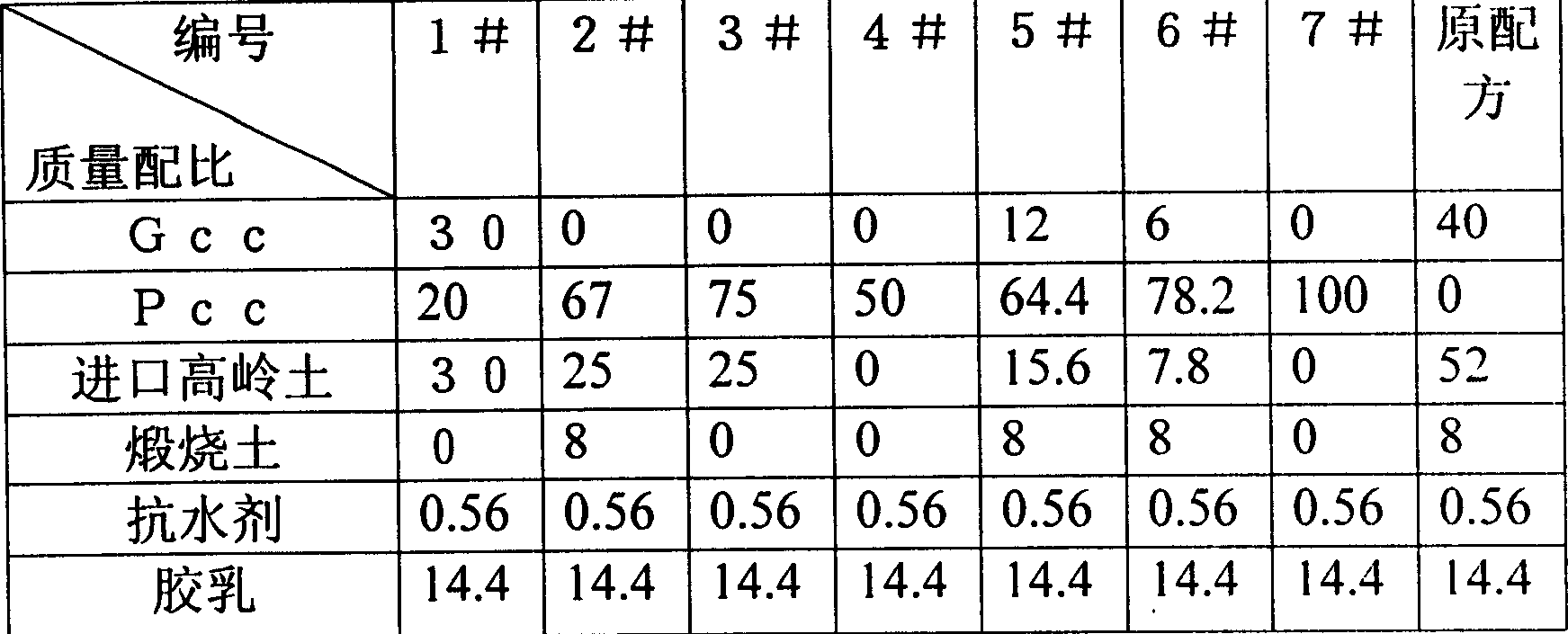

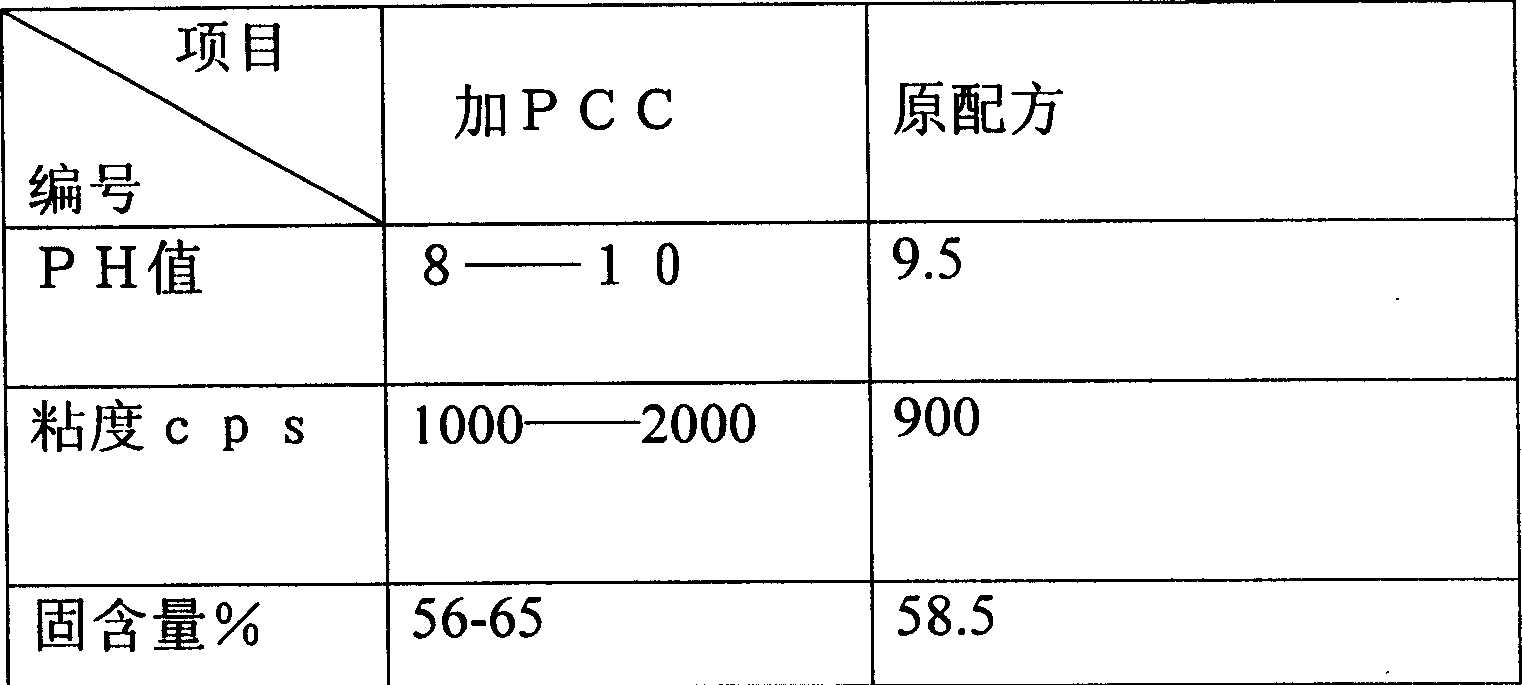

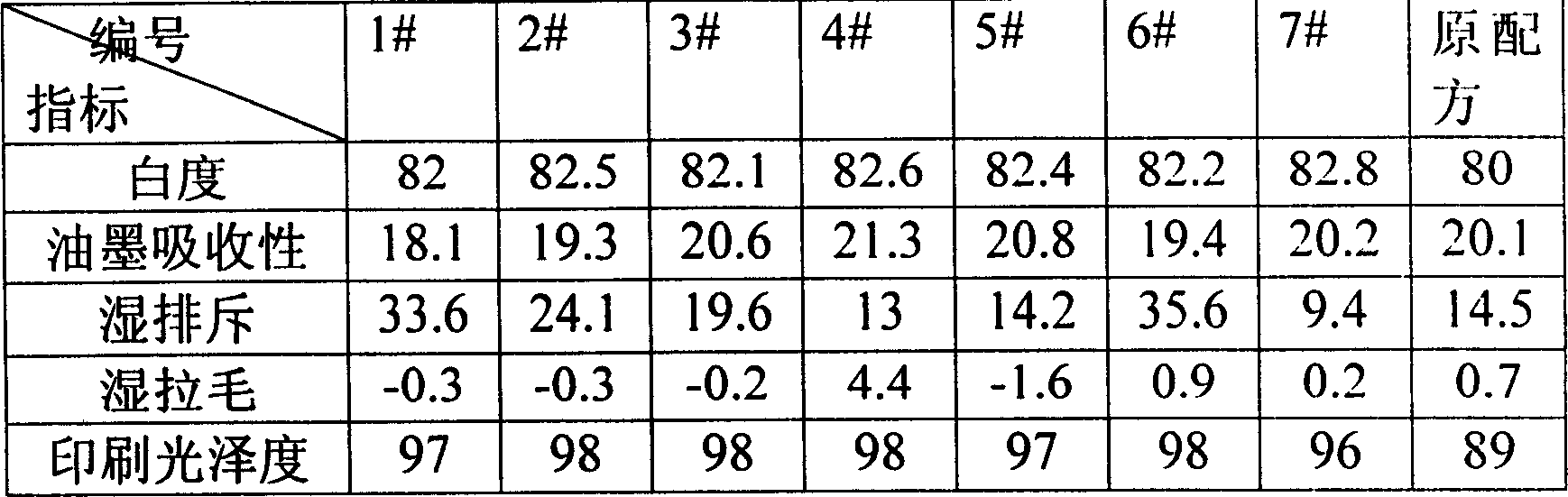

[0007] The present invention is a paint for papermaking surface coating, characterized in that: the composition and weight percentage of the paint are: 30-55% of light calcium carbonate, 5-10% of kaolin, and 0.1% of water-resistant agent -0.5%, the latex is 0.5-6%, and the balance is water; the components and weight percentages of the coating described in the specific implementation are: light calcium carbonate is 30-45%, heavy calcium carbonate is 1-10%, The content of kaolin is 5-10%, the anti-water agent is 0.1-0.5%, the latex is 0.5-6%, and the balance is water; the kaolin includes washed kaolin and calcined clay, and the washed kaolin accounts for 70-85% by weight of the kaolin, and the calcined The clay accounts for 15-30% by weight of the kaolin, the water-resistant agent is polyurea-formaldehyde resin, and the latex is generally commercially available latex.

[0008] In the following, li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com