Rubber extruding machine

A technology of rubber extruder and rubber raw material, applied in the field of rubber extruder, can solve the problems of loud noise, exhaust gas, environmental pollution, affecting the traveling speed of the piston rod 121, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

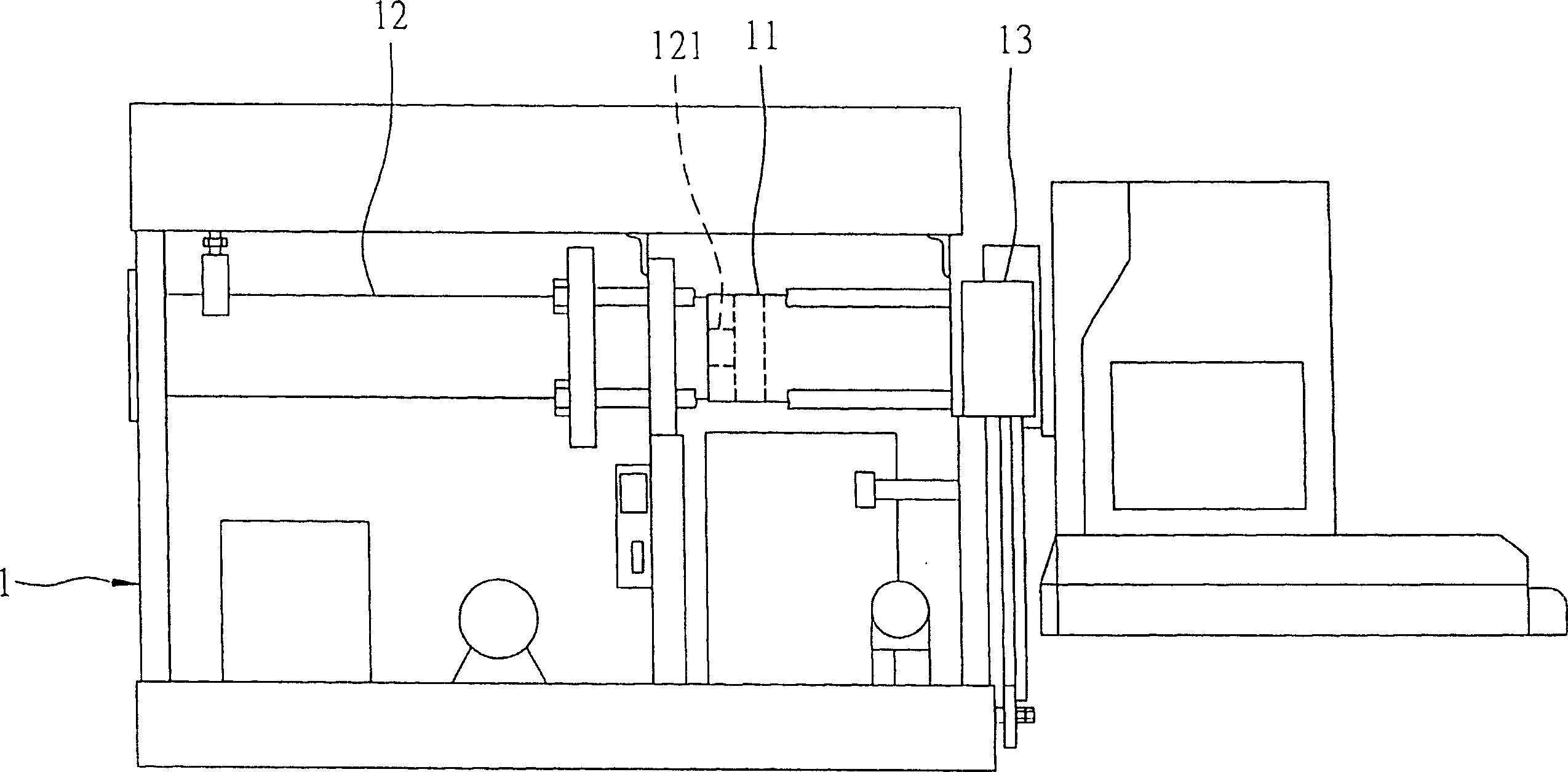

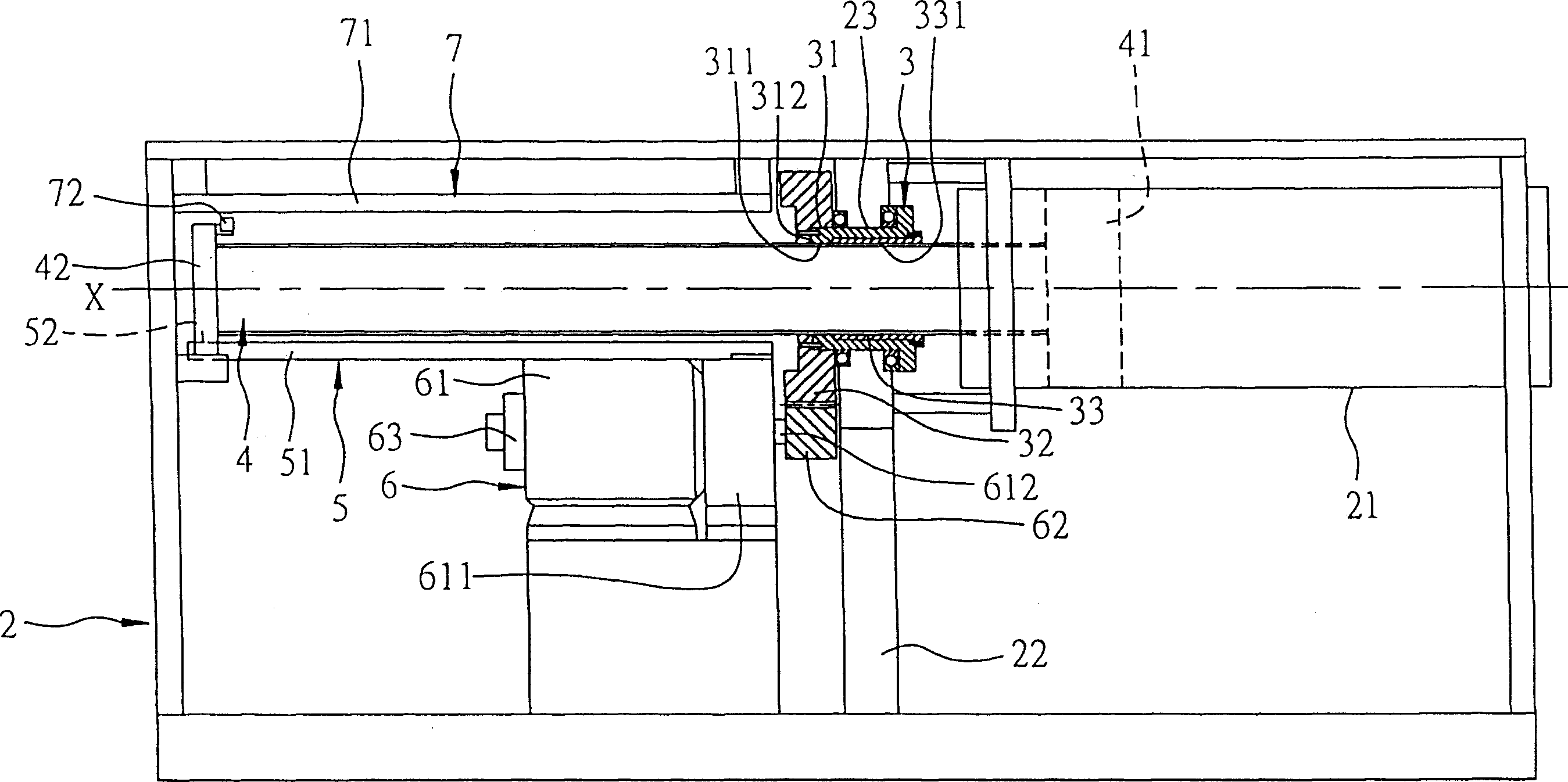

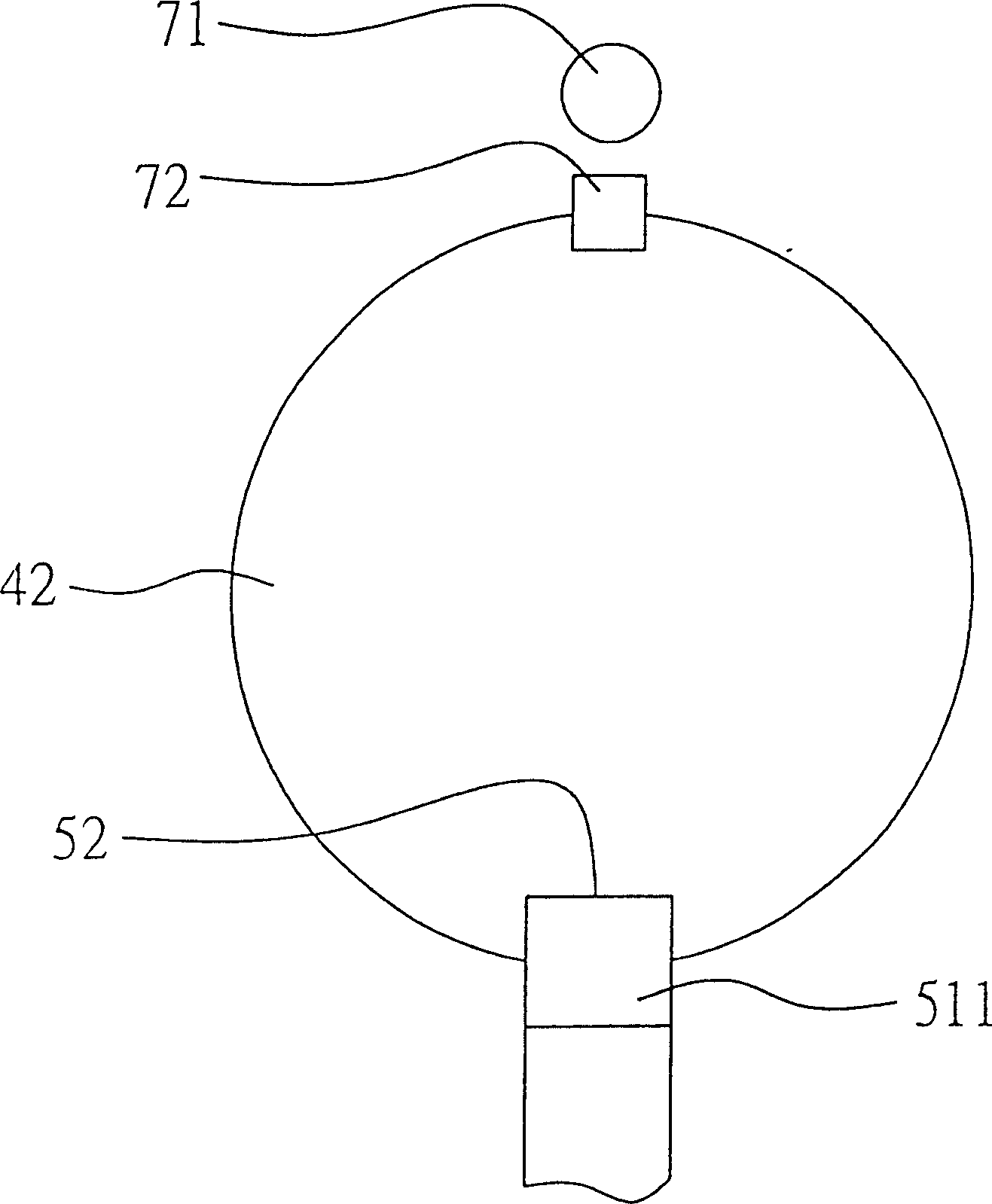

[0013] Such as figure 2 , image 3 , The preferred embodiment of the rubber extruder of the present invention includes a main body 2, a screw assembly 3, a pressure feeding screw 4, a limit assembly 5, a drive assembly 6 and a magnetic detection assembly 7.

[0014] The main body 2 has a rubber material cylinder 21 extending along an axis X for accommodating rubber materials, and a through hole 23 penetrating through a machine wall 22 along the axis X and opposite to the rubber material cylinder 21 .

[0015] The threaded assembly 3 has a gear sleeve 31 , a driven gear 32 and a shaft sleeve 33 pivoted in the through hole 23 of the body 2 . The gear sleeve 31 has a through hole 311 through which the shaft sleeve 33 penetrates along the axis X, and an exit end 312 through which the driven gear 32 is sleeved. The sleeve 33 has a threaded hole 331 extending along the axis X.

[0016] The pressure feeding screw 4 (which can be a kind of ball screw) is screwed with the screw hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com