Manufacture of head universal joint assembly and device for cutting ball bonding connection

A manufacturing method and universal joint technology are applied in the installation/connection of the transducing head relative to the arm parts, the configuration/installation of the recording head, the electrical connection between the arm and the arm frame, etc., which can solve the problem of high manufacturing cost The high proportion of HGA and the increase of average manufacturing cost of HGA

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

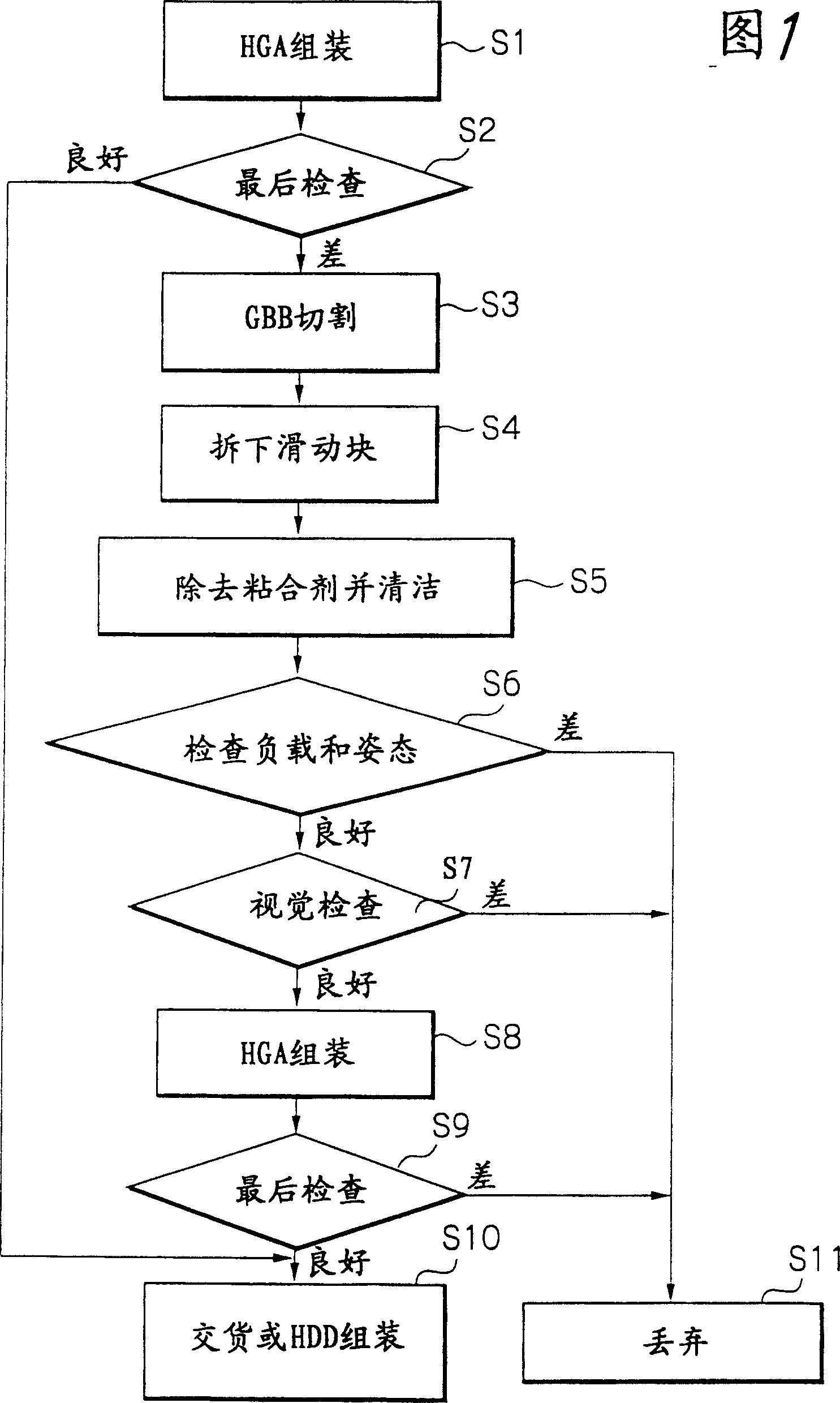

[0029] A method of manufacturing an HGA in a preferred embodiment according to the present invention will be described below with reference to FIG. 1. FIG.

[0030] First, the HGA is assembled according to a conventional manufacturing method (step S1). That is, by fixing the magnetic head slider having the thin-film magnetic head element on the top end portion of the wireless suspension by using an adhesive such as epoxy resin adhesive, and then using GBB to connect the connection soldering of the terminal electrode of the slider and the lead conductor pattern of the suspension. The pads are electrically connected, thereby assembling the HGA. An IC chip having a head driving circuit and a read signal amplifier circuit may be mounted on the lead conductor pattern extending backward from the suspension.

[0031] Then, a final inspection is performed using a DP tester to check whether the thin film magnetic head element has the required electrical properties (step S2). Products...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com