Power generation motor system for vehicle

一种发电电动机、电动机的技术,应用在同步发电机、控制发电机、交流电动机控制等方向,能够解决电池充放电电流增大、电动机特性恶化、发电效率降低等问题,达到抑制动作复位、变动减少、延长寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiment 1

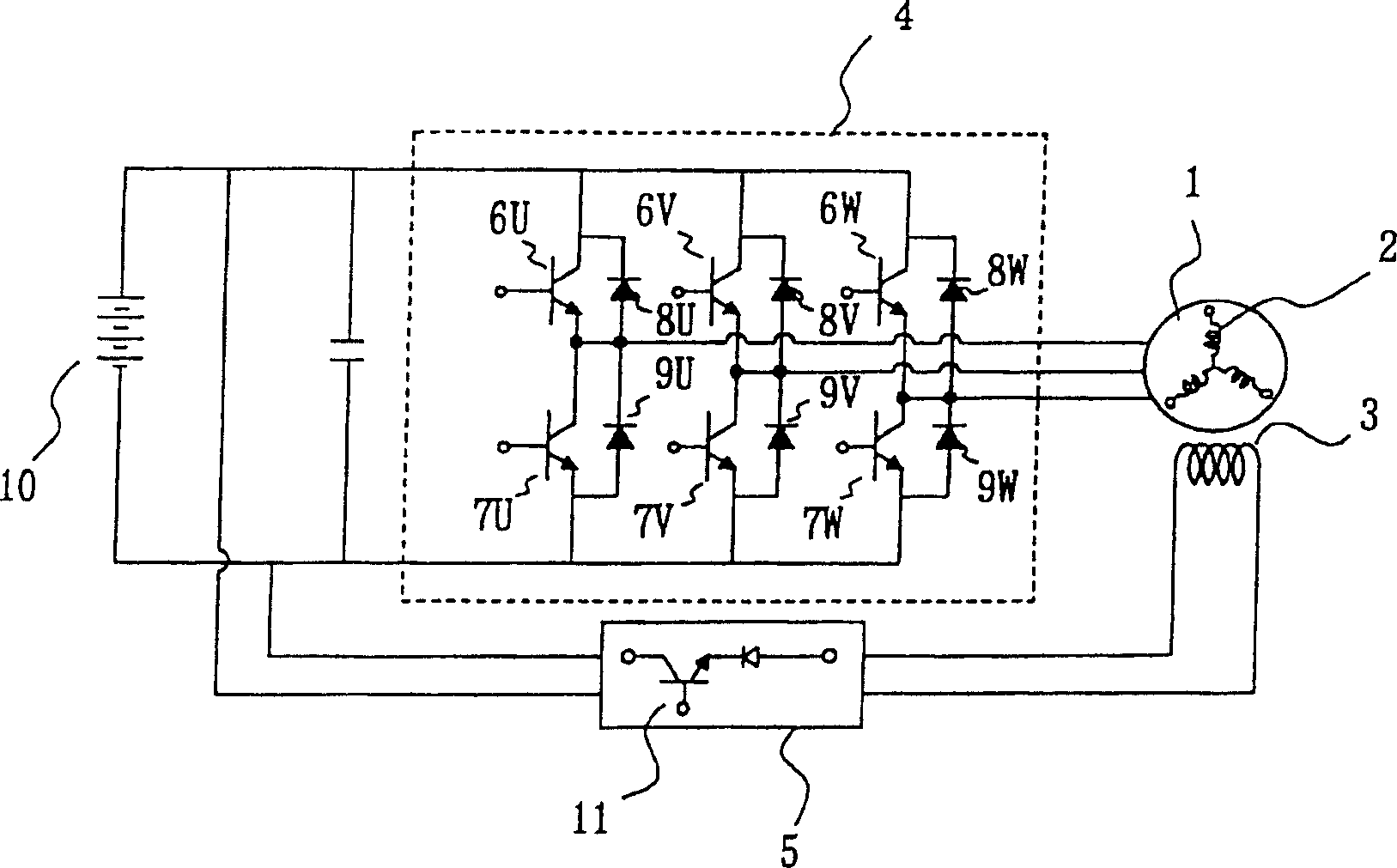

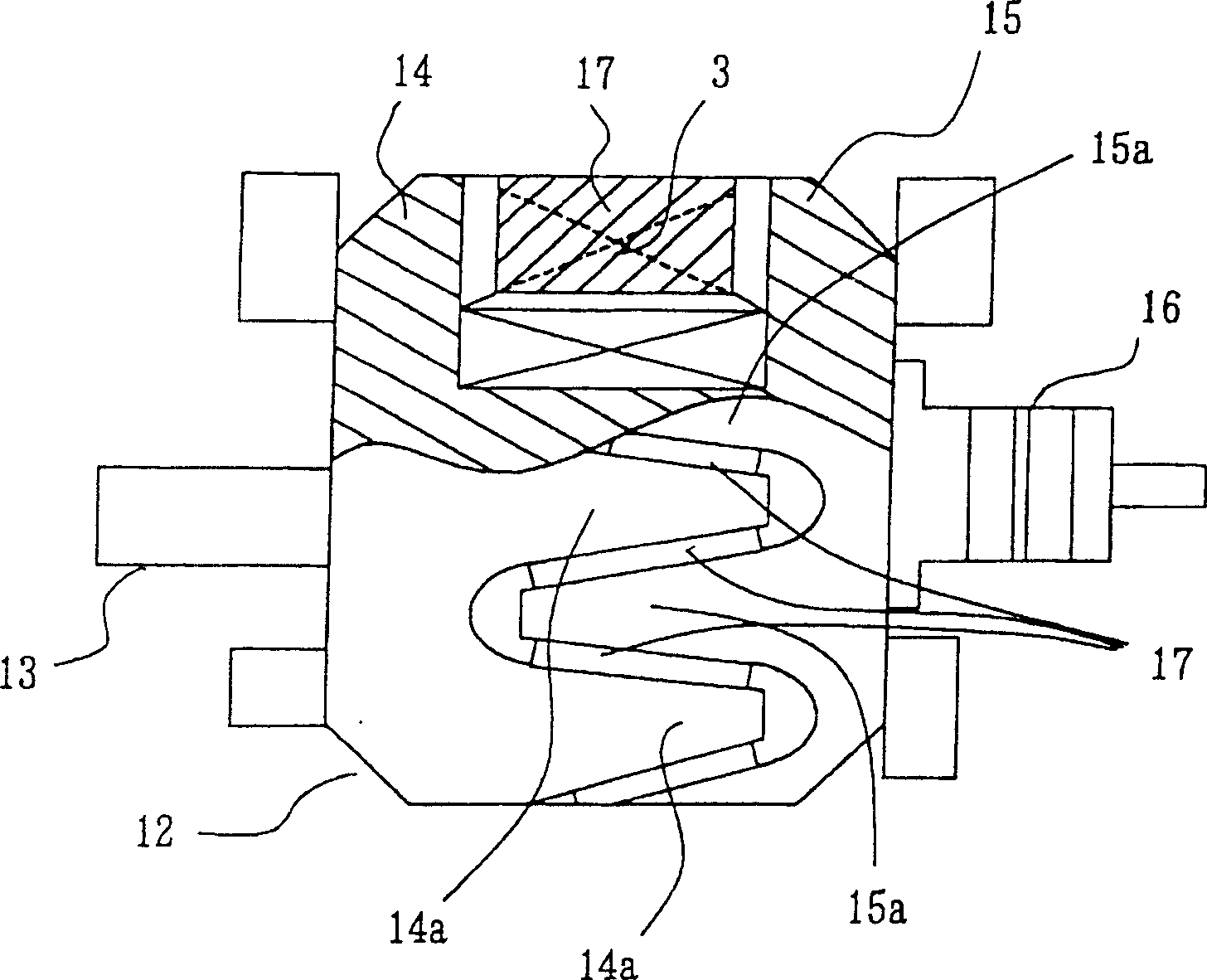

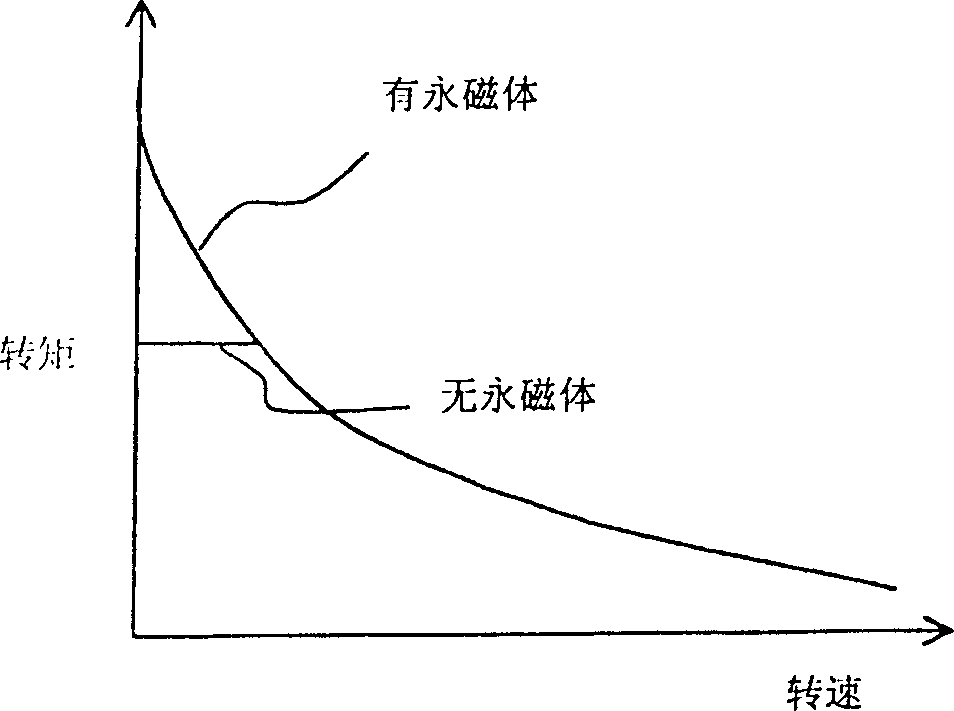

[0024] Figure 1 to Figure 6 Described is a vehicle generator-motor system according to Embodiment 1 of the present invention, figure 1 It is a system configuration diagram of a generator motor for a vehicle, figure 2 is a partial cross-sectional view showing an example of the structure of a rotor used in the vehicle generator-motor system according to the present embodiment, Figure 3 to Figure 6 A characteristic diagram illustrating the effect.

[0025] exist figure 1 Among them, the generator motor 1 has a three-phase armature winding 2, an excitation winding 3 and utilizes figure 2 A synchronous rotating electrical machine with permanent magnets for excitation as described later is mounted on a vehicle internal combustion engine, and functions as a starter motor when the internal combustion engine is started under the control of a control device not shown in the figure. To function as a charging generator, control commands from a control device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com