Process for adding drug sterilizing in water washing procedure at mfg. printed circuit board

A technology for printed circuit boards and fungicides, which is applied in the field of sterilization in the washing process of printed circuit boards, can solve the problems of filamentous copper slag of circuit boards, polluted water bodies, and the range and strength of contact cannot be effectively killed. Effects of rejection, copper dross ratio reduction, simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

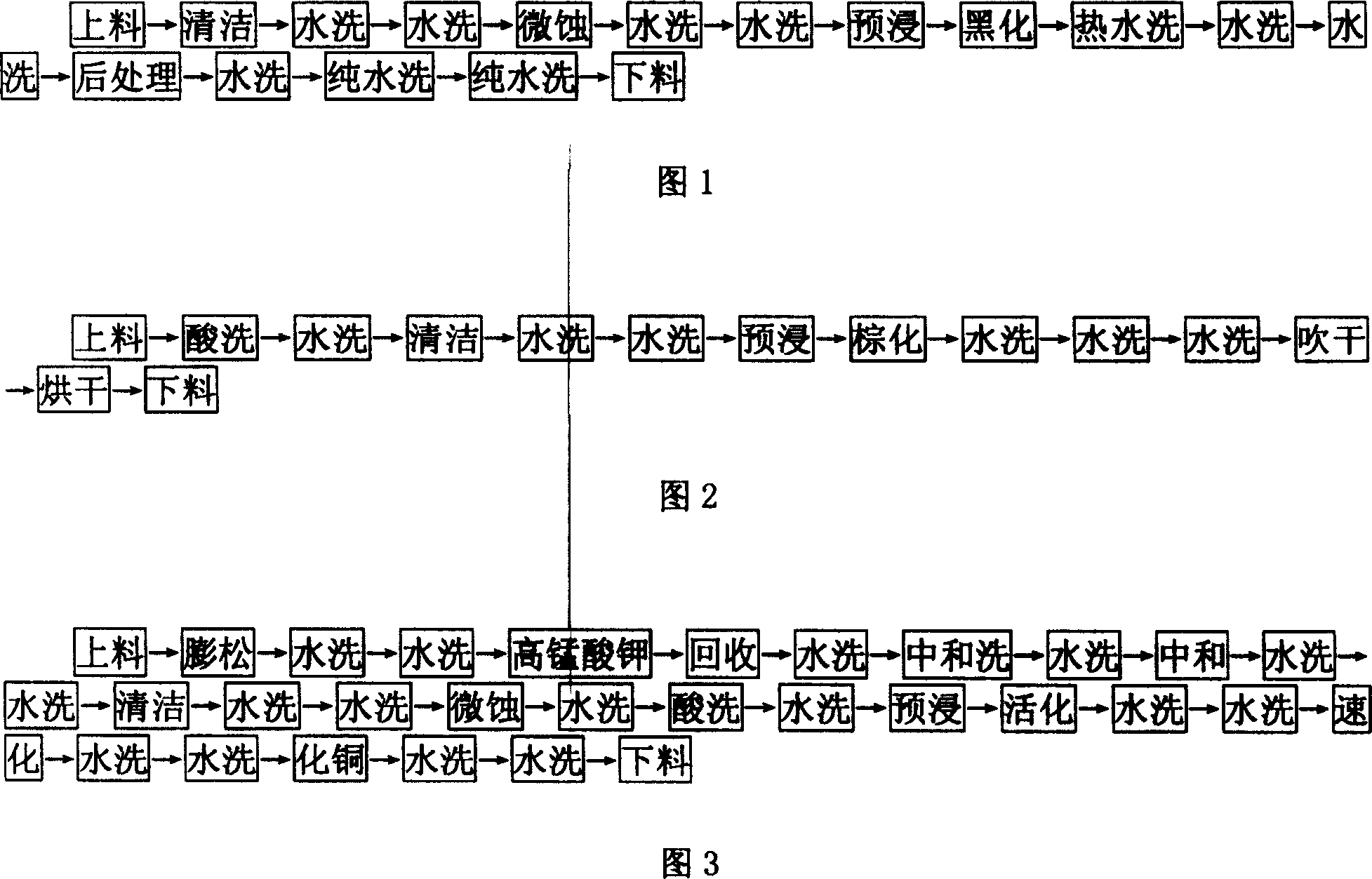

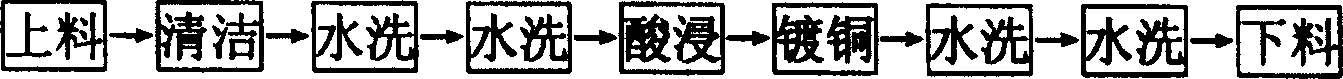

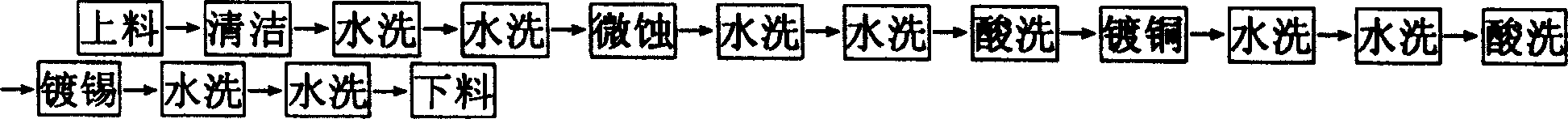

[0014] 1. Selected production line: Take the secondary copper process as an example,

[0015] The production process is: feeding, cleaning, washing 1, washing 2, micro-etching, washing 3, washing 4, pickling, copper plating, washing 5, washing 6, pickling, tin plating, washing, washing, cutting;

[0016] Note: The volume of the washing tank is about 1900L, and the flow rate is about 6-10L / min.

[0017] 2. Experimental method:

[0018] A. Select a second copper wire for testing, clean the second copper section, micro-etch, and add a fungicide to the washing tank (No. 1-6 washing tank, a total of 6 tanks) after copper plating.

[0019] B. Adding method of fungicide: Manually add once every 4 hours, add 300ml to each washing tank each time (that is, add 1.8L fungicide to 6 washing tanks each time, add 10.8L every day).

[0020] C. After the second copper wire is maintained, immediately start adding fungicide in the washing tank, record the amount and time of addition, last for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com