Line centering no-tillage sowing machine for wheat in farmland covered by corn stalk

A corn stalk and seeder technology, which is applied in the directions of sowing seeders, harvesters, crop processors, etc., can solve the problems of long farming hours, reduce the amount of stalks on the surface, and it is difficult to improve work efficiency, so as to reduce soil moisture evaporation and prevent soil The effect of churn and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

[0019] Attached below figure 1 - attached Figure 5 The implementation of the present invention is described.

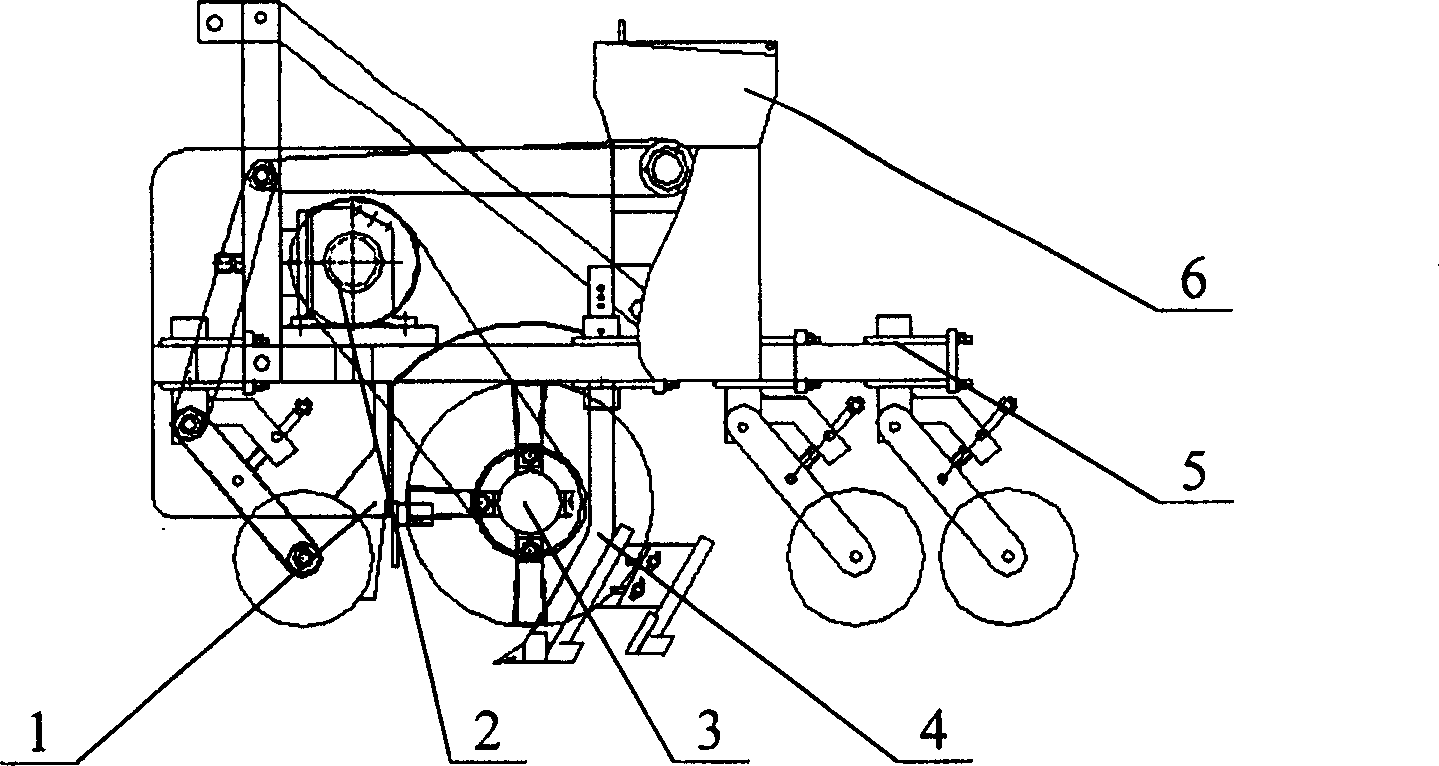

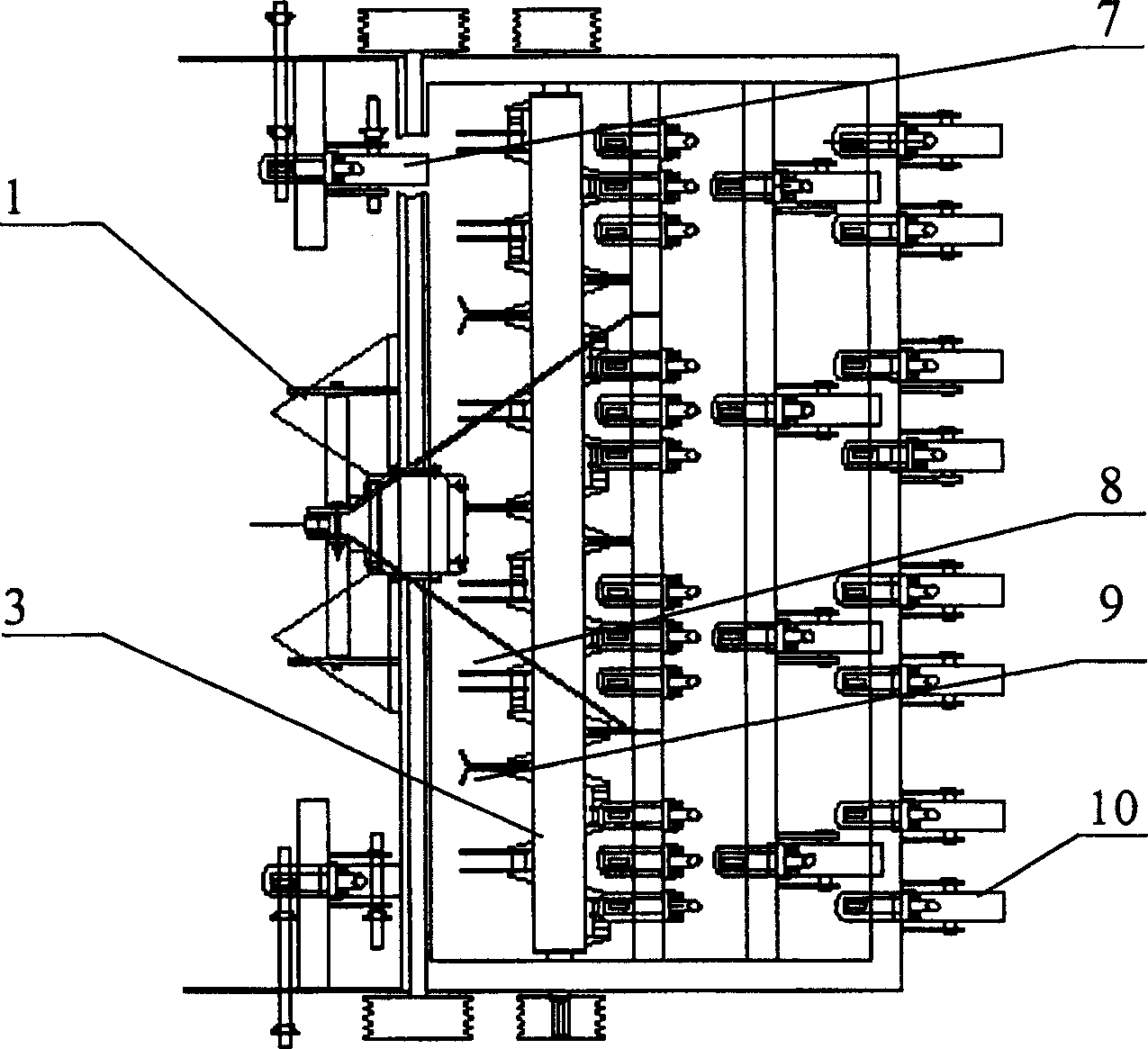

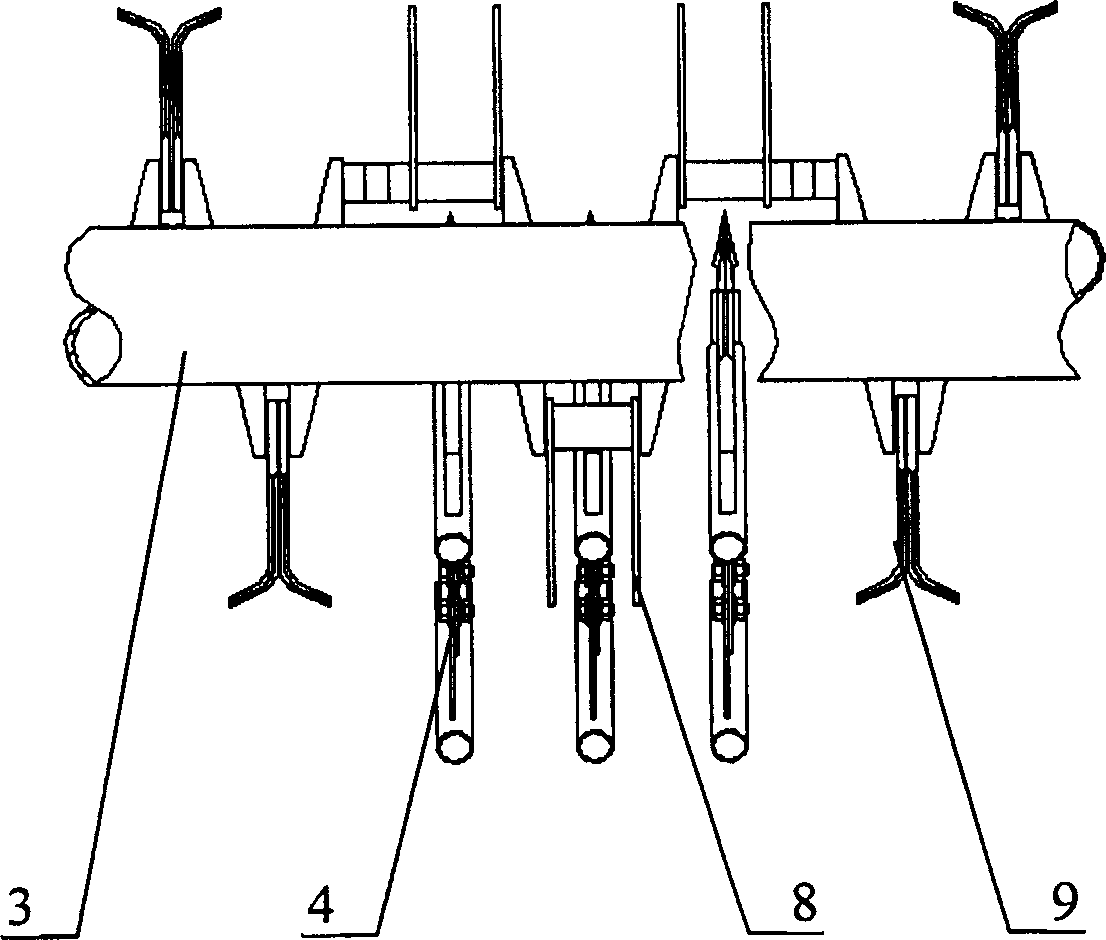

[0020] As shown in the figure, 5 is the frame, 2 is the power transmission system, 3 is the cutter shaft, 4 is the ditch opener for seed row and fertilizer discharge, 6 is the seed fertilizer box, 7 is the ground wheel, 10 is the pressing wheel, the straw collector The strip device 1 is placed in front of the frame 5, and is used to collect the straw into strips; the transmission system 2 is the power source for the rotation of the cutter shaft 3; the ground wheel 7 is the power source for the fertilizer box 6; the straw anti-blocking straight Knife 8 is used to remove the stalks and weeds mounted on the ditch opener 4 for seeding and fertilizer discharge; the stalk chopping knife 9 is used for chopping corn stalks.

[0021] During operation, by planning the walking mode, the straw collector 1 walks between the corn rows and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com