Vacuum microwave dehydration plant

A dehydration device and vacuum microwave technology are applied in the fields of dehydration preservation of fruits/vegetables, food preservation, food science, etc., which can solve the problems of high production cost, restricted promotion and application, and large energy consumption, and achieve large-scale, low-cost, Retain the original flavor, good recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

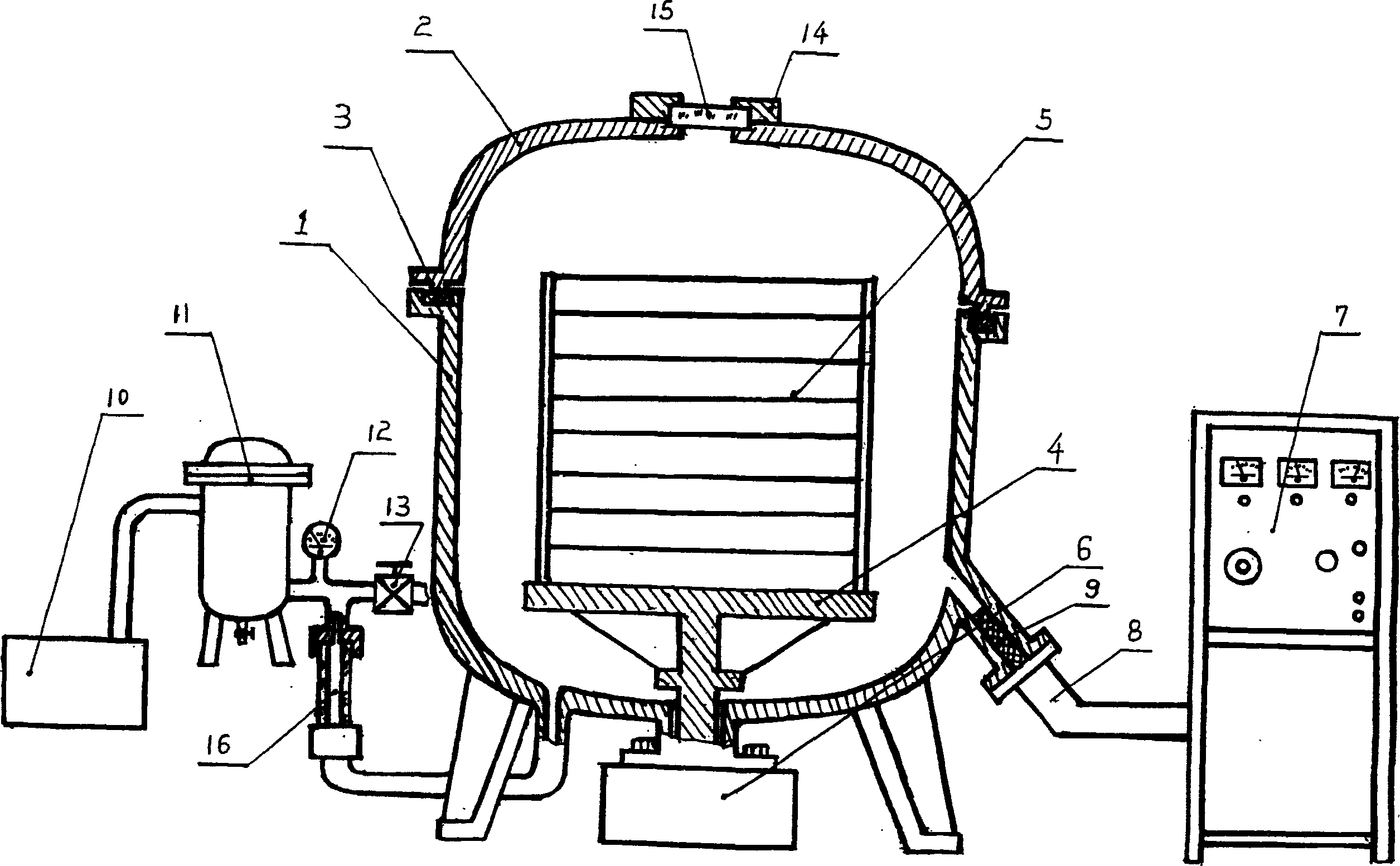

[0010] The present invention mainly consists of the substrate 1 of the negative pressure sealing chamber, the cover 2 of the negative pressure sealing chamber, the silicone rubber sealing ring 3, the rotating tray 4, the food or medicine to be dried and the shelf 5, the rotating device 6 of the rotating tray, and the microwave power generator. Device 7, microwave waveguide 8, air-tight high-frequency solution in microwave waveguide 9, vacuum pump 10, vacuum buffer tank 11 vacuum gauge 12 air release valve 13, observation window glass pressure ring 14, observation window glass 15, water vapor observation Condensation glass tube 16 etc. are formed.

[0011] The negative pressure sealing chamber cover 2 is used to cover the base body 1 of the negative pressure sealing chamber. The silicone rubber sealing ring 3 is poured into the flange cavity of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com