Integral stretching technology of double (three)-tank stainless steel water tanks

A technology of stainless steel and sink, applied in the field of kitchen utensils, can solve the problems of inability to reach deeper dimensions, water splashes, lack of practical significance, etc., achieve good practical significance, avoid missing welding, and have good price advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The overall stretching process of the present invention will be further described in detail below in conjunction with the above-mentioned drawings and taking the model of the mother-in-law double groove as 28211 as an example. The process is as follows:

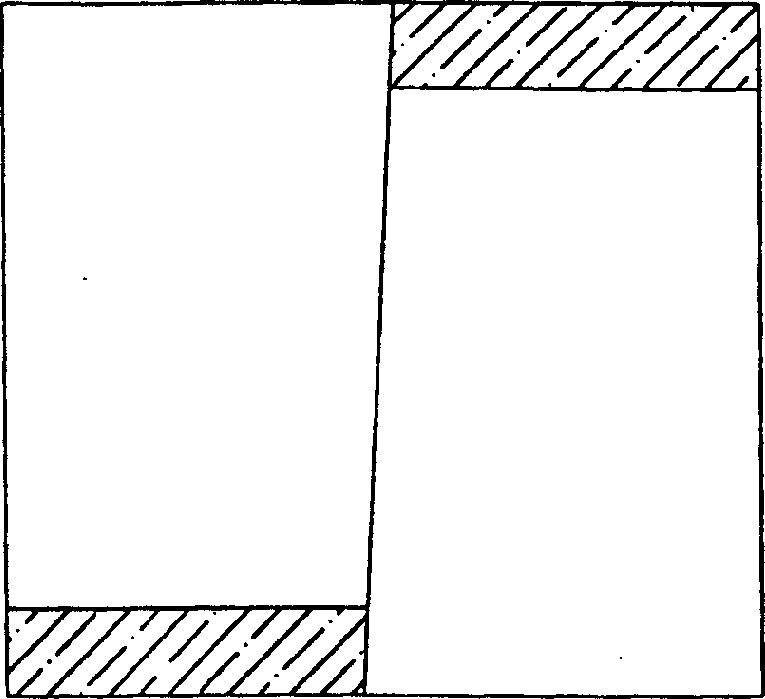

[0042] (1) Cutting material: send the stainless steel grade SUS304 and the specification of 1×1219×C coil material into the shearing machine and cut it into the required expansion size of the water tank ( figure 1 ), in order to save material, adopt paired shearing;

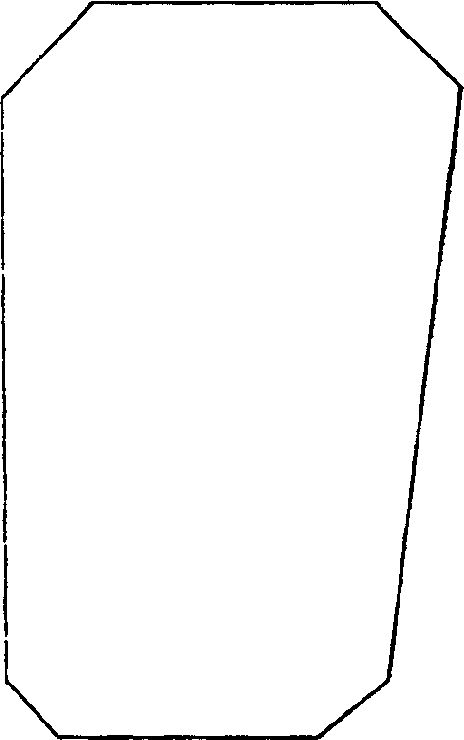

[0043] (2) Corner cutting: Send the flat material after blanking into the shearing machine, and cut the excess material at the four corners ( figure 2 ), to prevent wrinkling in the next stretching process;

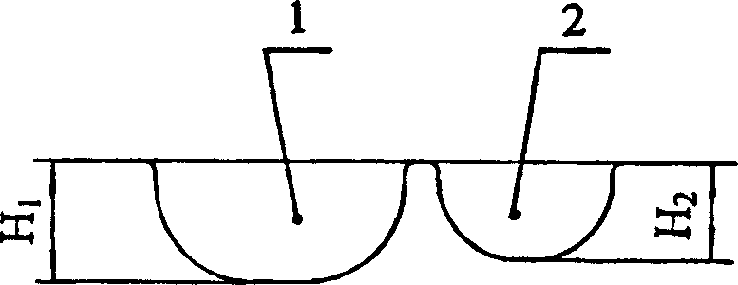

[0044] (3) The first stretching: Send the flat material after cutting the angle into the 630T hydraulic press. In order to prevent the material flow of individual parts and prevent the phenomenon of pulling cracks, the stretching ribs must be reaso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com