Method for producing Sushi rice

A production method and technology of rice, applied in the preparation of vinegar, food preparation, confectionery, etc., can solve the problems of dehydration, aging of rice grains, affecting the taste, etc., and achieve the effect of long storage time and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

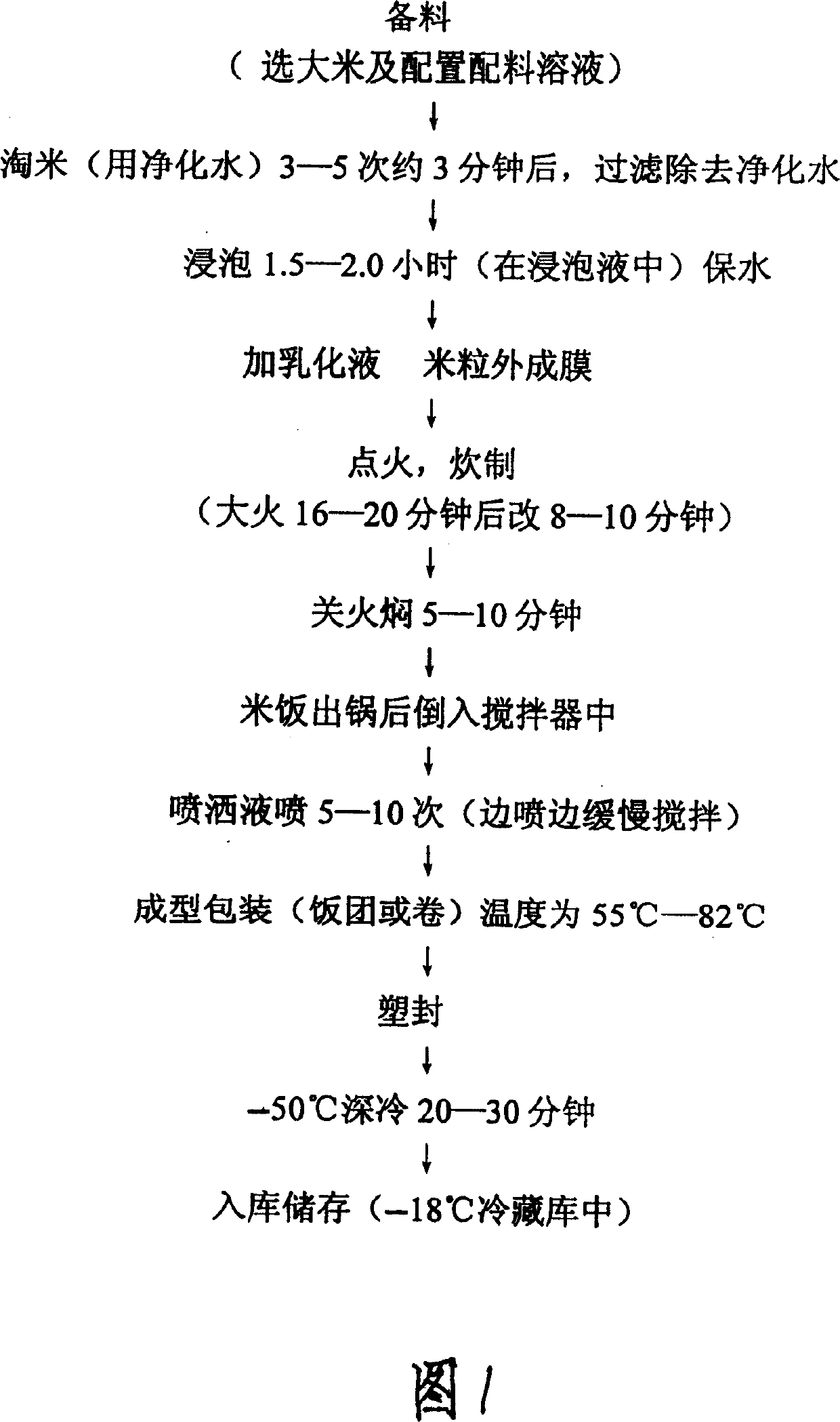

[0025] Embodiment 1: as shown in Figure 1: the production method is divided into the following operations in order:

[0026] (1) Choose rice that meets the edible standard or high-quality rice, and the taste of the rice made is better;

[0027] (2), ingredients:

[0028] No. 3 material liquid: Weigh 90 grams of table salt, 45 grams of sodium citrate, 10 grams of sodium tripolyphosphate, 75 grams of xylitol, add 4100 grams of purified water, and then stir evenly to make a solution to form a soaking liquid;

[0029] No. 5 material liquid: Weigh 1.2 grams of sodium carboxymethyl cellulose, 1.7 grams of guar gum, 2 grams of edible gelatin, 21 grams of maltodextrin, 47 grams of edible salad oil, add 800 grams of purified water, and place in the homogenate Homogenize in the machine for 3-5 minutes to make an emulsion;

[0030] No. 4 material liquid: weigh 150 grams of soft white sugar, 220 grams of trehalose, 155 grams of white vinegar, and 237 grams of white rice vinegar, mix and...

Embodiment 2

[0047] (1) Choose rice that meets the edible standard or high-quality rice, and the taste of the rice made is better;

[0048] (2), ingredients:

[0049] No. 3 material liquid: Weigh 42 grams of table salt, 42 grams of sodium citrate, 10 grams of sodium tripolyphosphate, 150 grams of mannitol, add 4050 grams of purified water, stir fully, and make a solution to form a soaking liquid;

[0050] No. 5 material liquid: Weigh 1.3 grams of sodium carboxymethyl cellulose, 1.7 grams of guar gum, 2 grams of edible gelatin, 2 grams of maltodextrin, 47 grams of edible salad oil, add 800 grams of purified water, and place in the homogenate Homogenize in the machine for 3-5 minutes to make an emulsion;

[0051] No. 4 material liquid: Weigh 45 grams of soft white sugar, 180 grams of trehalose, 135 grams of xylitol, add 390 grams of purified water and stir to dissolve, because it has high permeability and special flavor, sour agent and sugar Mix in proportion to make a sweet and sour solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com