Etherified-cross linked-pregelated ternary composite modified starch, its preparing process and application

A ternary technology of compound modified starch and pregelatinization is applied in the field of starch modification to achieve the effect of scientific and practical process design and easy popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

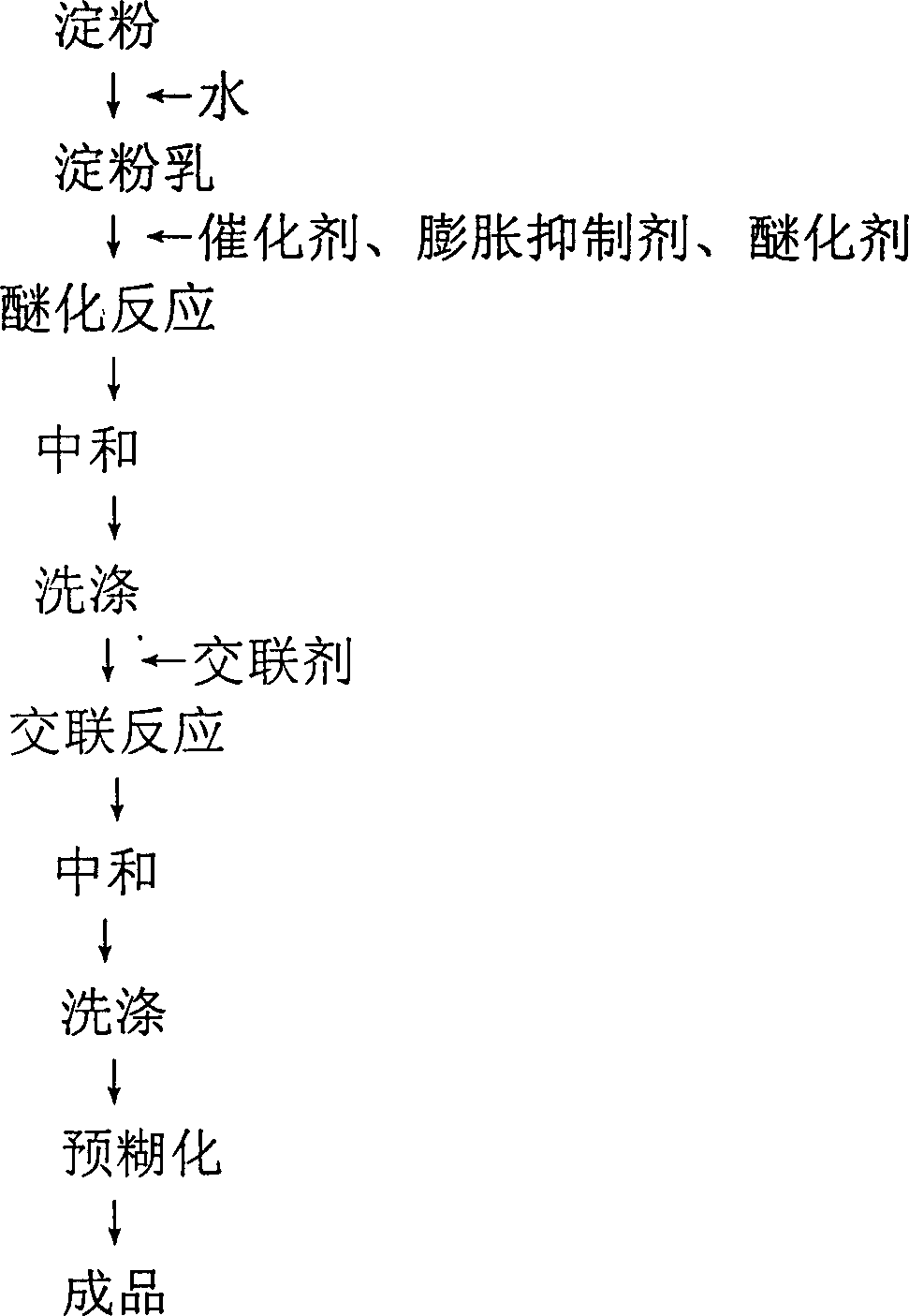

Method used

Image

Examples

Embodiment 1

[0027] Add water to 800g of starch and slurry into starch milk with a mass fraction of 40% (dry basis), add catalyst and expansion inhibitor according to the above-mentioned proportion of the instructions, then add 64g of propylene oxide, and control the temperature at 45°C in a closed container. -50°C, pH10.5-12.0, react for 8-24h, neutralize, wash, adjust the slurry to 40%, control the temperature at 25-30°C, adjust the pH7.5-9.0 with 3% hydrochloric acid solution, drop while stirring Add 36g of adipic acid and acetic anhydride mixture, add dropwise for 0.5-4h, neutralize, wash, adjust the slurry until 40% of the upper roller is pregelatinized, the temperature is 110°C-150°C, the time is 2-8min, and the product is obtained .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com