Simultaneously acid hydrolysis and esterizing modified composite modified starch and its preparing method and use

A technology of compound modified starch and esterification reaction, which is applied in the field of modified starch to achieve good economic benefits, cost reduction, and scientific and practical process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

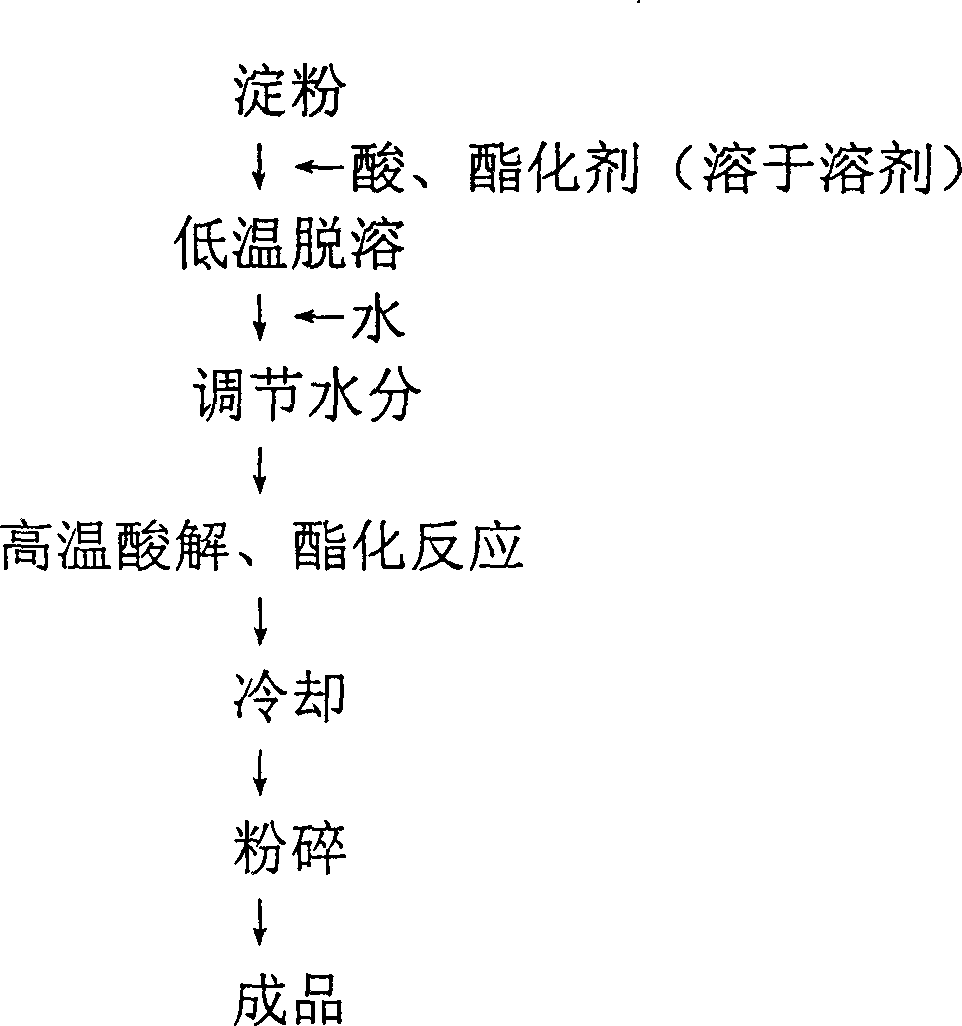

Method used

Image

Examples

Embodiment 1

[0020] Weigh 3g of stearic acid, dissolve it in 80ml of absolute ethanol at 70°C, then slowly add it to 100g of starch (dry basis), and keep stirring, then add 1ml of 2mol / L hydrochloric acid, and keep stirring, pass through 10 mesh Sieve into granules, place at 50°C, dry for 1 hour, cool down, measure the moisture mass fraction, then adjust the moisture mass fraction to 20%, and balance for 24 hours, then place at 150°C, react for 3 hours, cool, pulverize, pack, and obtain Finished starch stearate.

[0021] Degree of substitution

[0022] Degree of substitution

[0023] Note: The viscosity is measured by NDJ-79 rotary viscometer at 90°C.

Embodiment 2

[0025] Taking linoleic acid as an esterifying agent, all the other formulas and operating conditions are the same as in Example 1 to obtain the finished product linoleic acid starch ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com