Method and system of controlling dummy dispense

A technology of liquid and formula, which is applied in the direction of jet program control, photo-plate-making process coating equipment, photo-plate-making process exposure device, etc., can solve the problems of increasing the manufacturing cost of semiconductor integrated circuits, so as to improve product yield and prevent wafer coating Cloth, prevent re-doing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

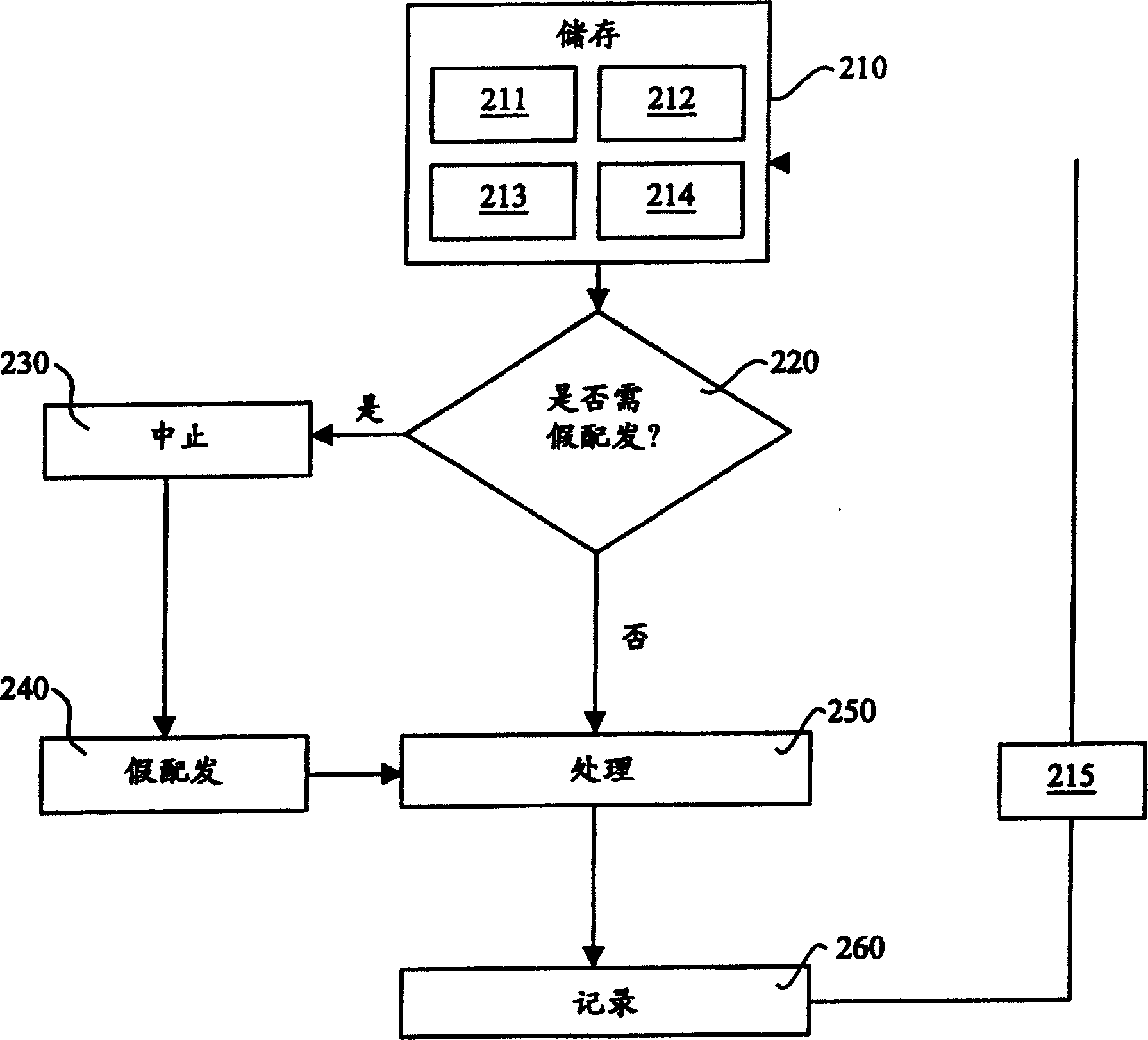

[0015] figure 2 A flow chart of a method for controlling fake distribution according to an example of the present invention is shown. exist figure 2 In the preferred embodiment shown, the method includes a storing step 210 , a comparing step 220 , an aborting step 230 , a pseudo-dispensing step 240 , a processing step 250 and a recording step 260 .

[0016] The storage step 210 is used to record the time 211 when the substrate is processed and the time 212 when the liquid is dispensed. In some embodiments, the storing step 210 also records the recipe 213 of the dispensed liquid and the name 214 of the liquid.

[0017] The time 211 when processing the substrate can be, for example, the time in any process when processing the substrate, such as the time of moving in and moving out of the substrate in any process. The substrate can be, for example, a semiconductor wafer substrate, a liquid crystal display substrate [such as a thin film transistor liquid crystal display (TFT ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com