Method and apparatus for manufacturing optical fiber preforms using the outside vapor deposition process

An external vapor deposition, optical fiber preform technology, used in glass manufacturing equipment, manufacturing tools, glass deposition furnaces, etc., can solve the problem of cooling the preform for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in more detail below with reference to the embodiments shown in the drawings.

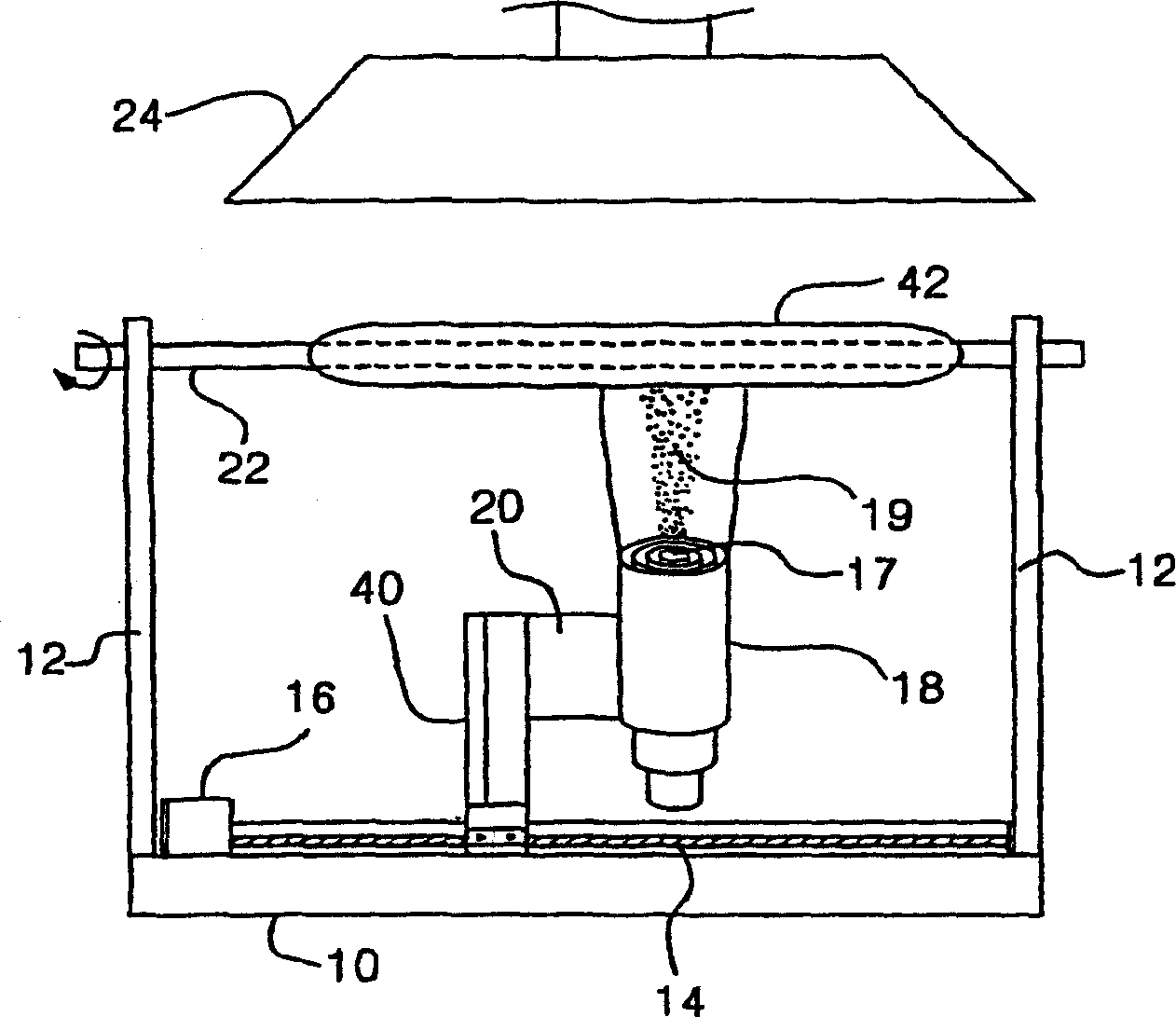

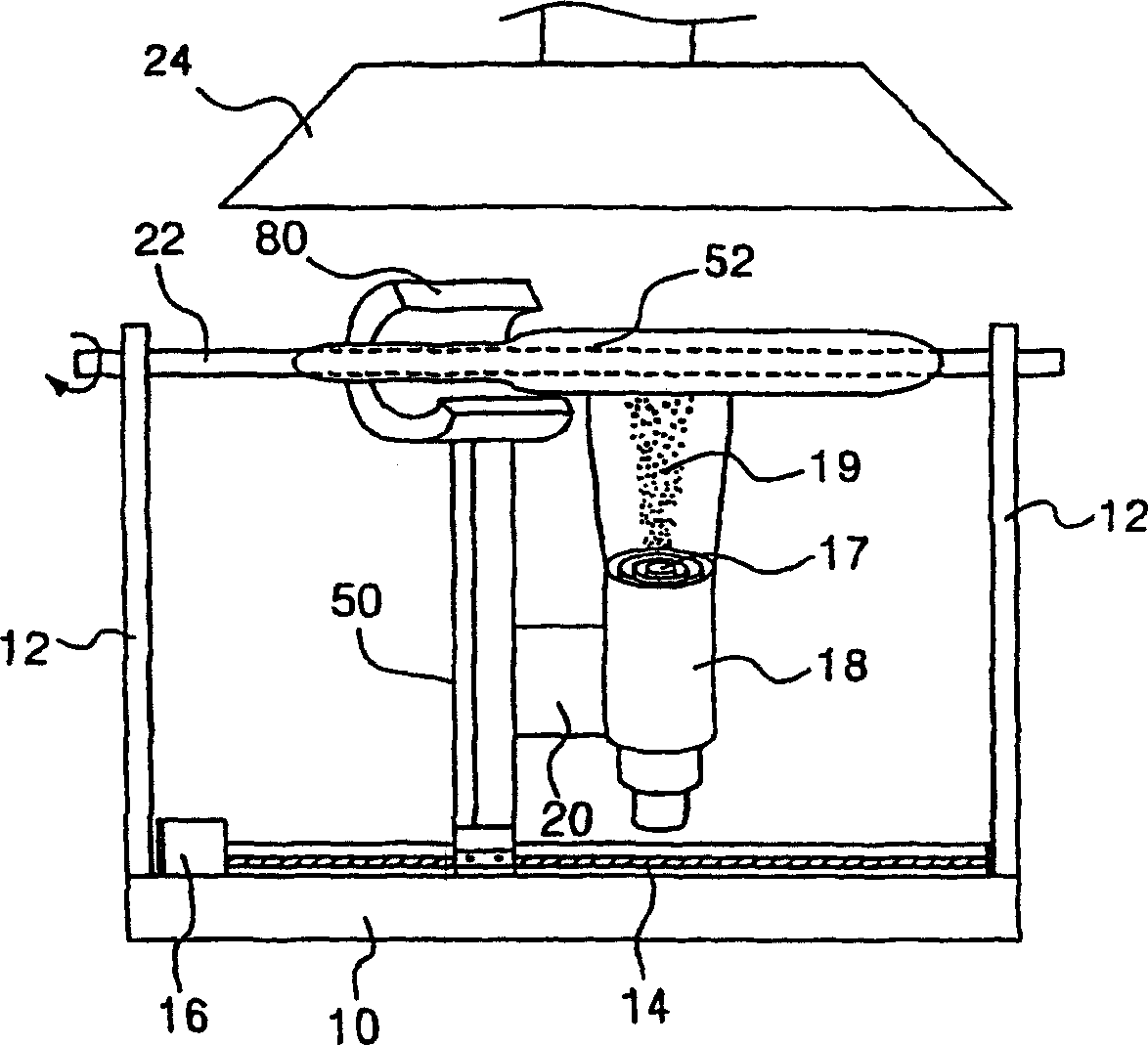

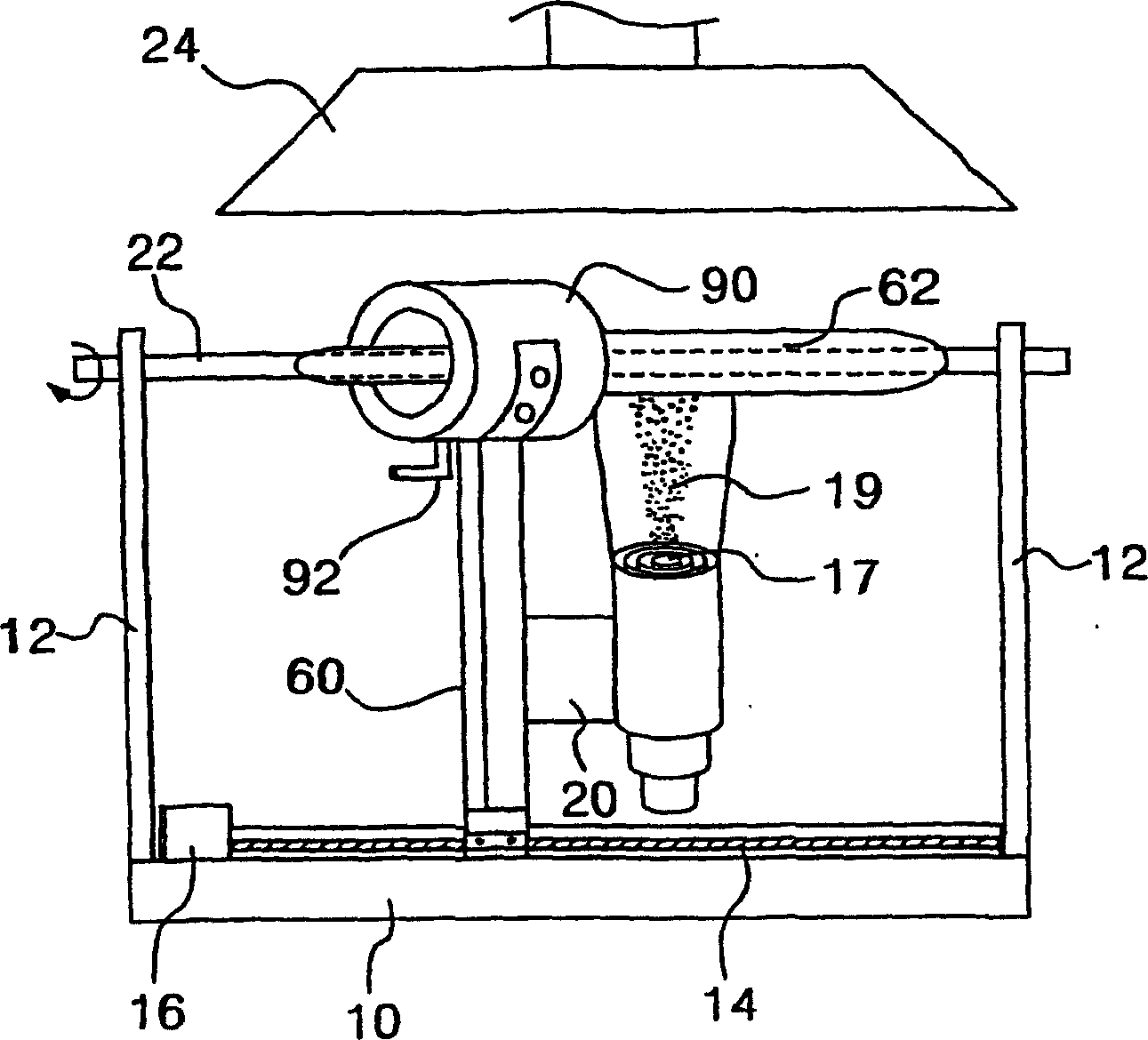

[0049] The present invention provides an apparatus for manufacturing an optical fiber preform using an outside vapor deposition (OVD) method. figure 2 is a schematic diagram of an optical fiber preform manufacturing apparatus according to an embodiment of the present invention. image 3 is a schematic diagram of an optical fiber preform manufacturing apparatus according to another embodiment of the present invention.

[0050] exist figure 2 and image 3 in, with figure 1 The corresponding components adopt the same figure 1 The same reference numerals are used, so descriptions thereof are omitted.

[0051] like figure 2 or image 3 As shown, the optical fiber preform manufacturing equipment includes: a deposition torch 18, suitable for spraying flame hydrolyzate 19 on the rotating circular target rod 22, so as to deposit a cladding 52 on the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com