Low-consumption permanent-magnet offset external rotor radial magnetic bearing

A permanent magnet bias, low power consumption technology, applied in the direction of bearing, shaft and bearing, shaft, etc., can solve the problems of weakening the suction force of the permanent magnet to the rotor shaft, losing too much magnetomotive force, large excitation current, etc. Operation stability, low power consumption, and the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

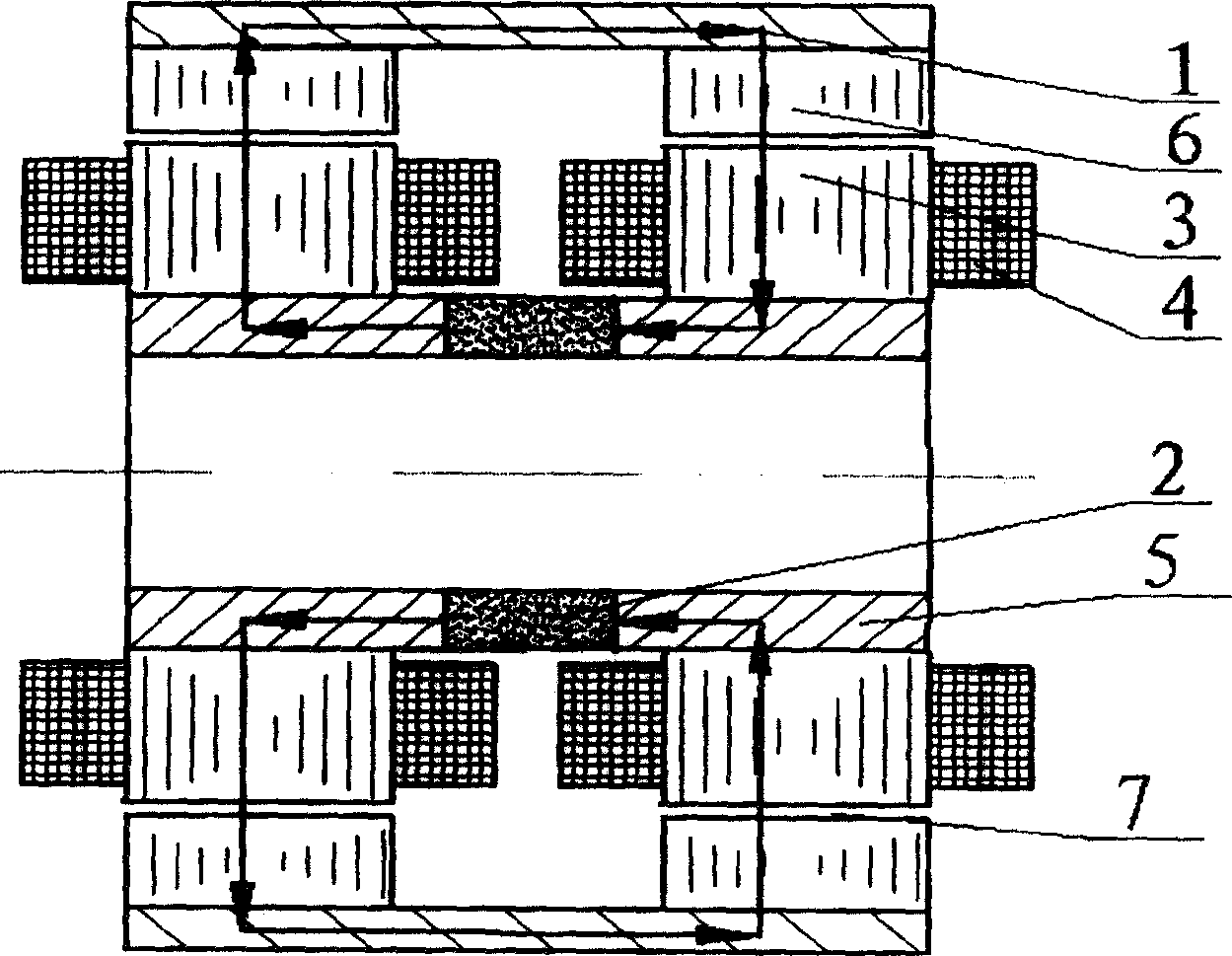

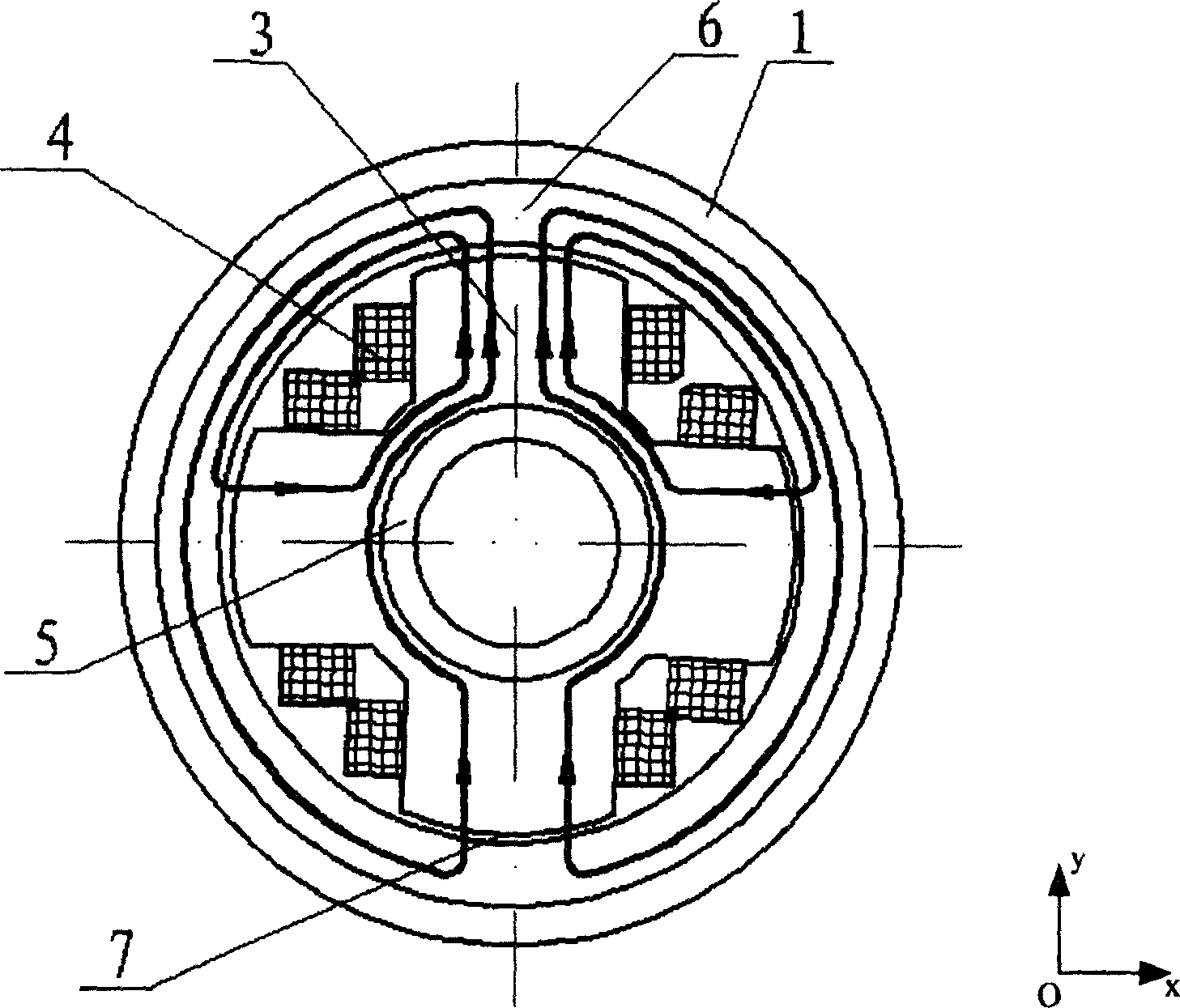

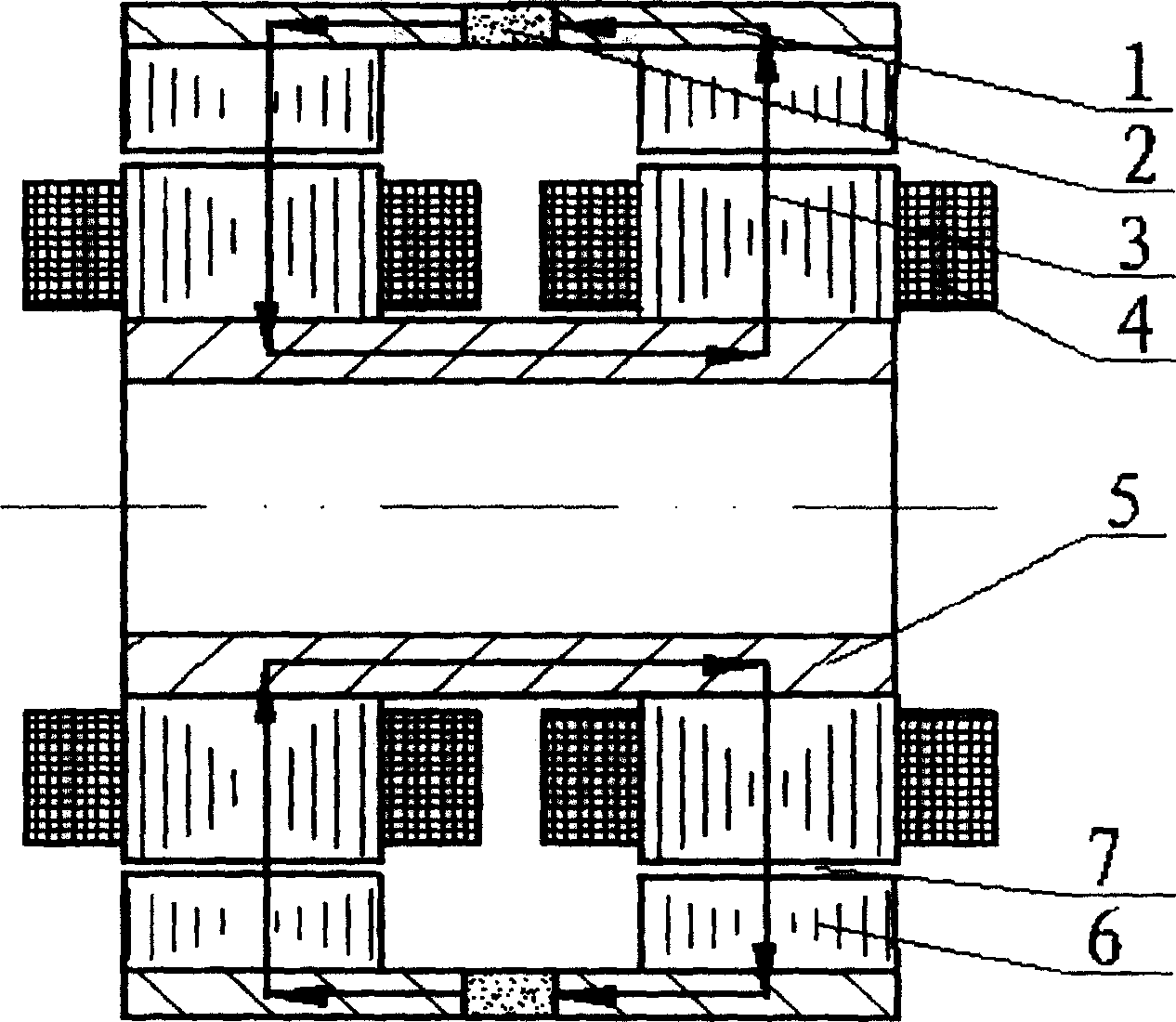

[0014] Such as figure 1 , 2 As shown, it is one of the technical solutions of the present invention, the inner magnetic steel, the inner excitation coil, the low power consumption permanent magnet bias outer rotor radial magnetic bearing, which is the basic form of the present invention, and it consists of an outer magnetic ring 1, 1 permanent magnet 2, 2 stator cores 3, 8 excitation coils 4, 2 inner magnetic rings 5, 2 rotor cores 6, 8 air gaps 7, each stator core 3 consists of 4 magnetic poles, 2 A stator core 3 forms 8 magnetic poles at the left and right ends of the magnetic bearing, which respectively form the magnetic poles in the positive and negative directions of the X and Y axes. The magnetic ring 1 is connected with the rotor core 6, the interior of the rotor core 6 is the stator core 3, and there is a certain gap between the outer surface of the stator core 3 and the inner surface of the rotor core 6, forming an air gap 7, and the inner magnetic ring 5 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com