Method for modifying thermoplastic engineering plastics by using glass fibre and its equipment

A glass fiber and engineering plastic technology, applied in the field of glass fiber modified thermoplastic engineering plastics, can solve the problems of inability to add lengths, glass fiber waste glass fibers can not be used, uneven fibers, etc., to save costs and be beneficial to environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A method for glass fiber modified thermoplastic engineering plastics. It adds glass fibers in the molten state of thermoplastic engineering plastics, and extrudes modified engineering plastics after stirring. The added glass fibers are glass fibers with uneven lengths, and their lengths are not more than 8 cm. The addition of the glass fiber can be added in a vibration state, which is that the vibration frequency is 50 Hz, and of course it can be at any value in the range of 20-200 Hz. The aforementioned thermoplastic engineering plastic is nylon 66, and of course the method of the present invention is also suitable for nylon 6 syndiotactic polystyrene or polymethylene terephthalate or polybutylene terephthalate or polystyrene.

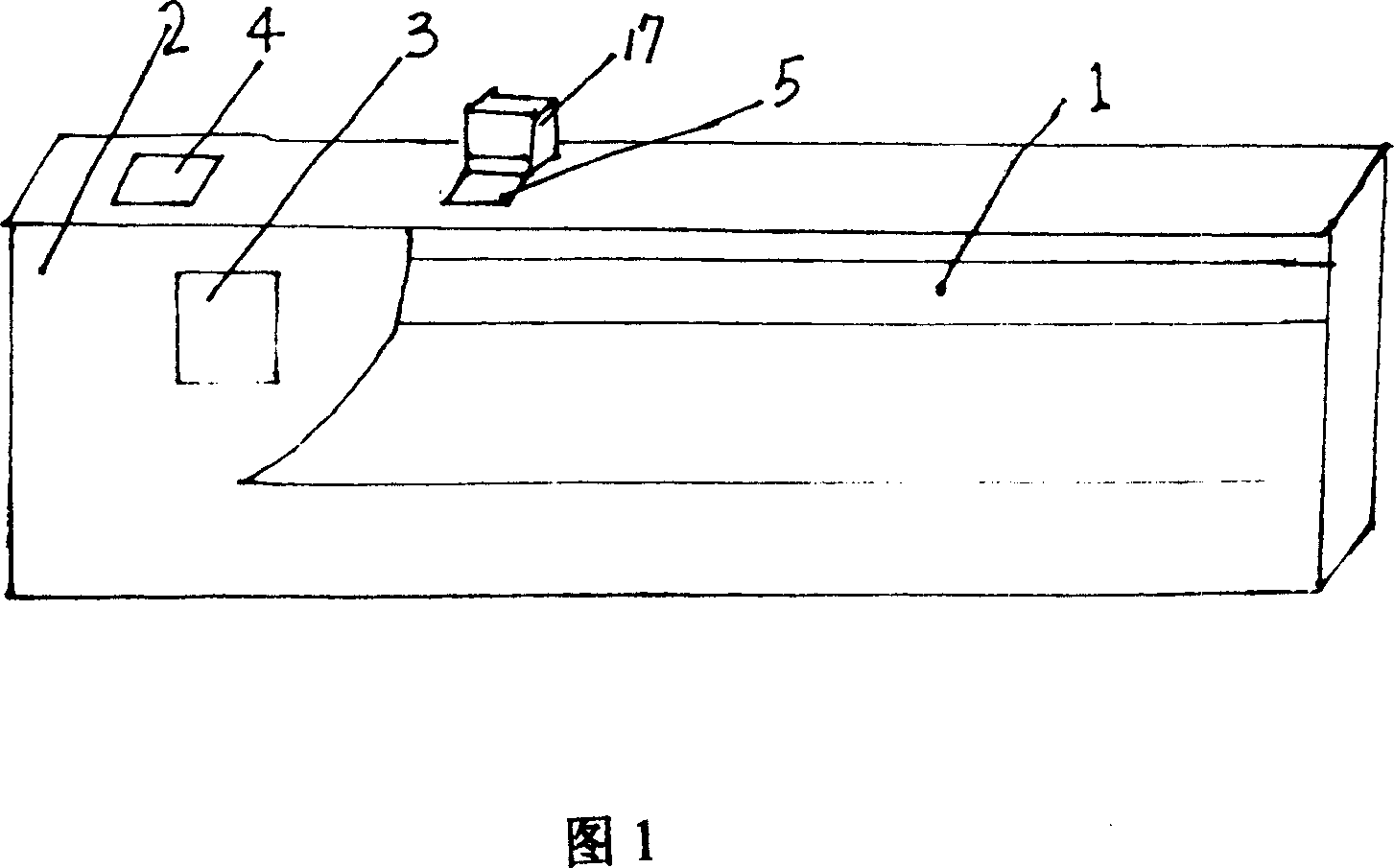

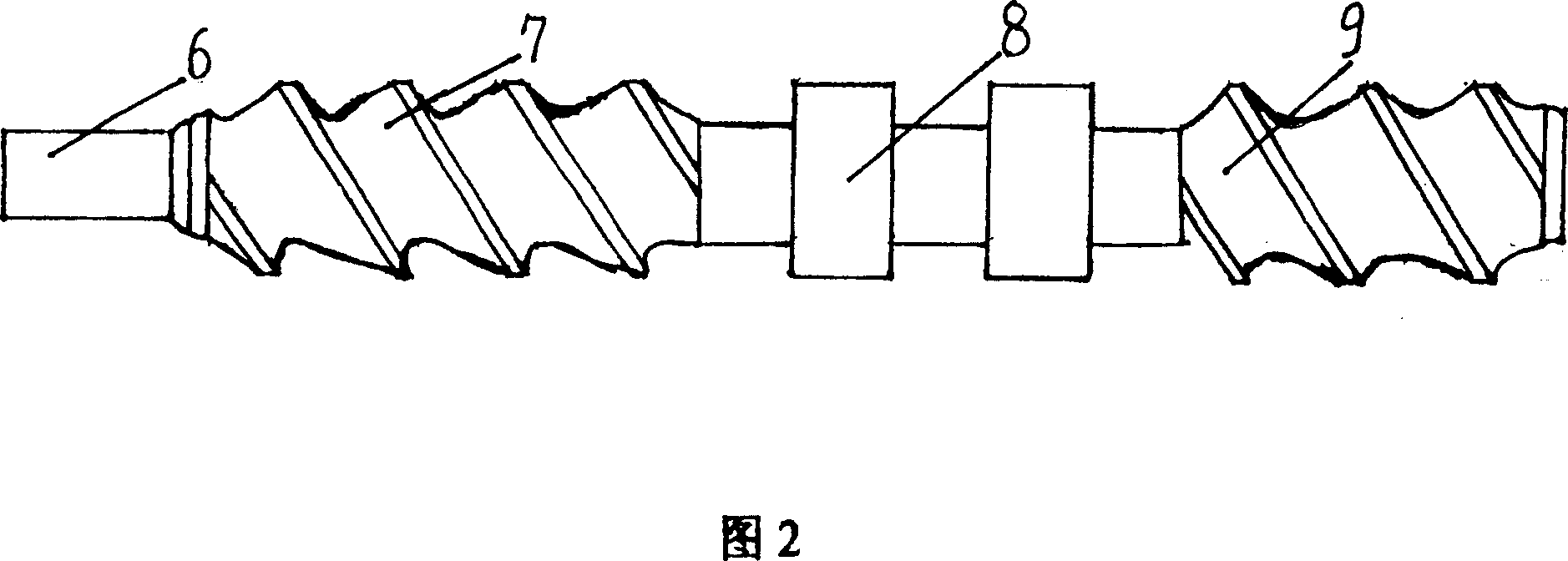

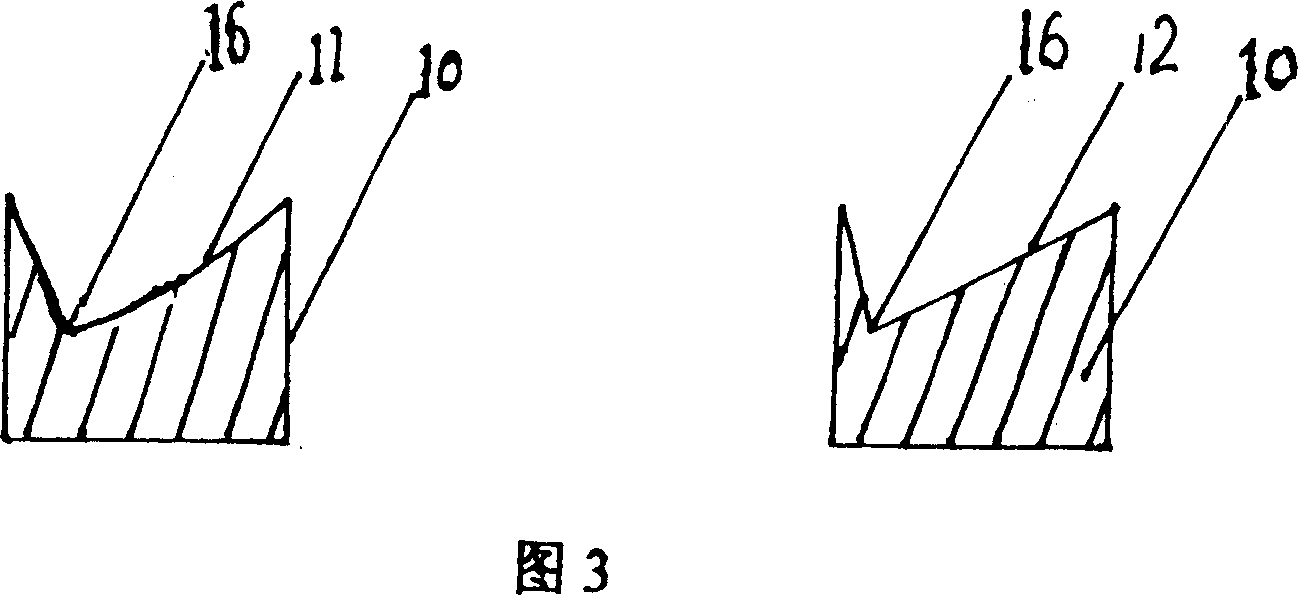

[0015] The above-mentioned equipment for glass fiber modified thermoplastic engineering plastics. Its production equipment comprises twin-screw extruder as shown in Figure 1, Figure 2, Figure 3, and described twin-screw extruder comprises two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com