Capacitance type pressure sensing element structure and mfg. method

A manufacturing method and sensing element technology, applied in electrical digital data processing, character and pattern recognition, instruments, etc., can solve problems such as poor effect, complex composition materials, sensor noise, etc., to improve sensing effect and reduce thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

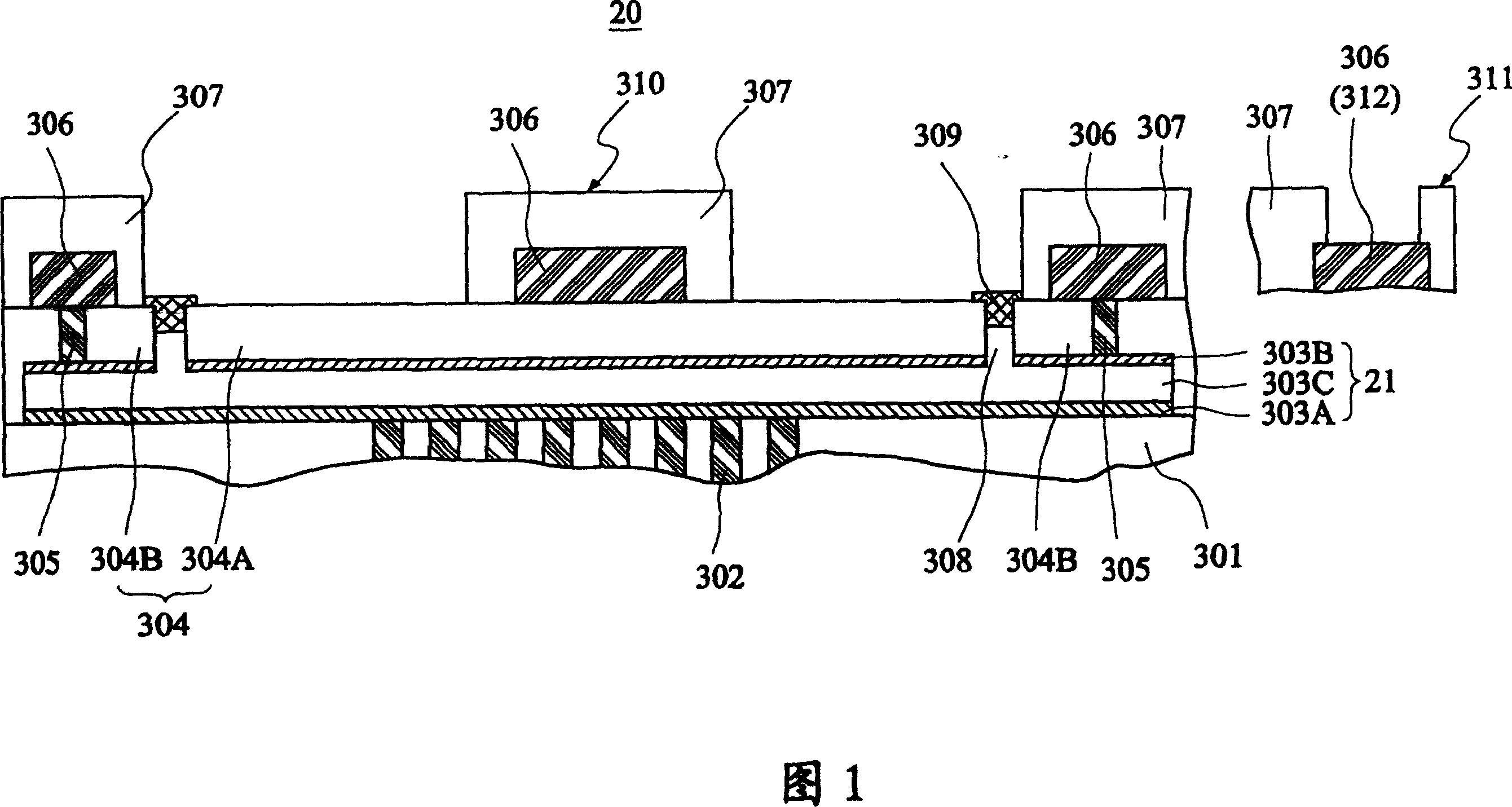

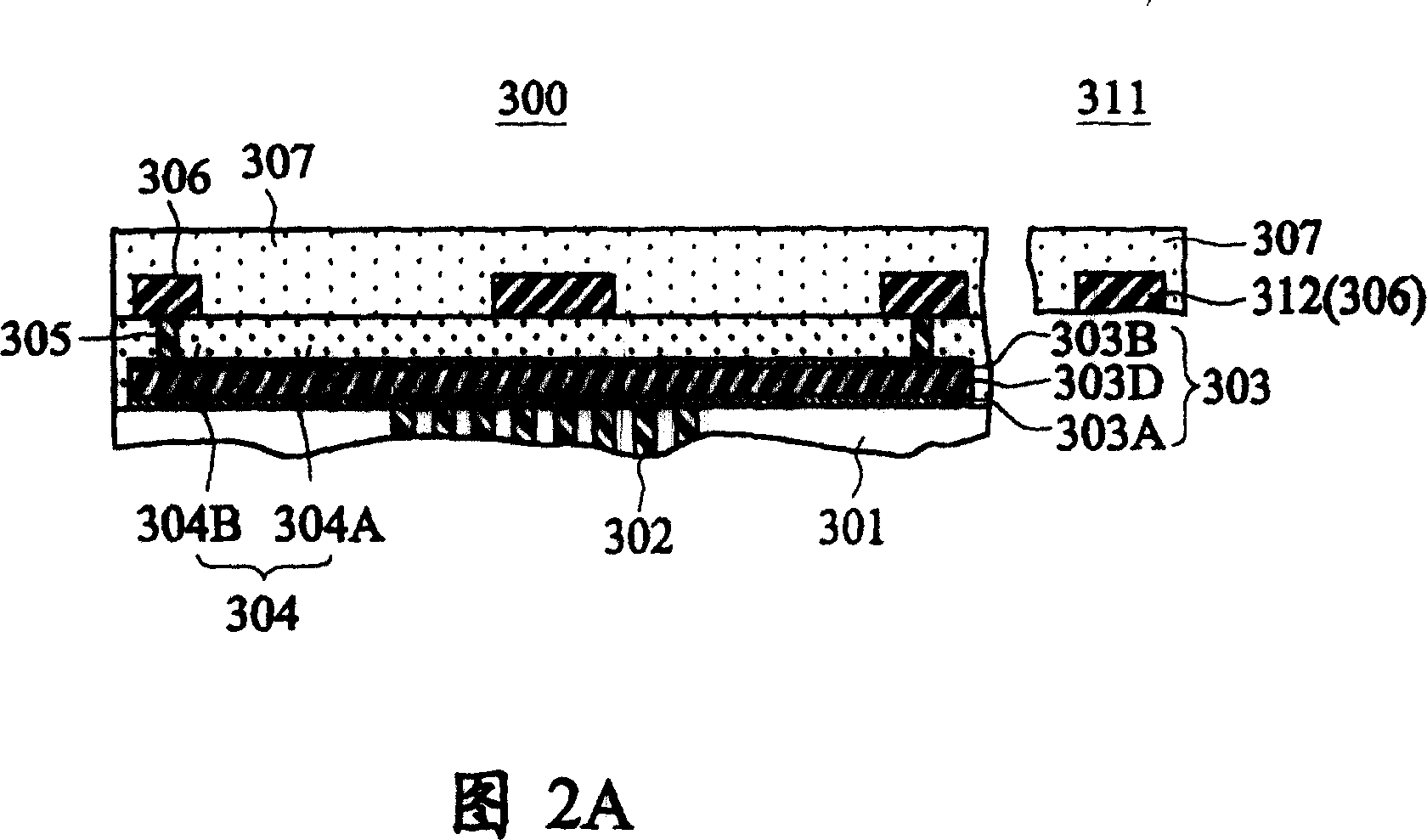

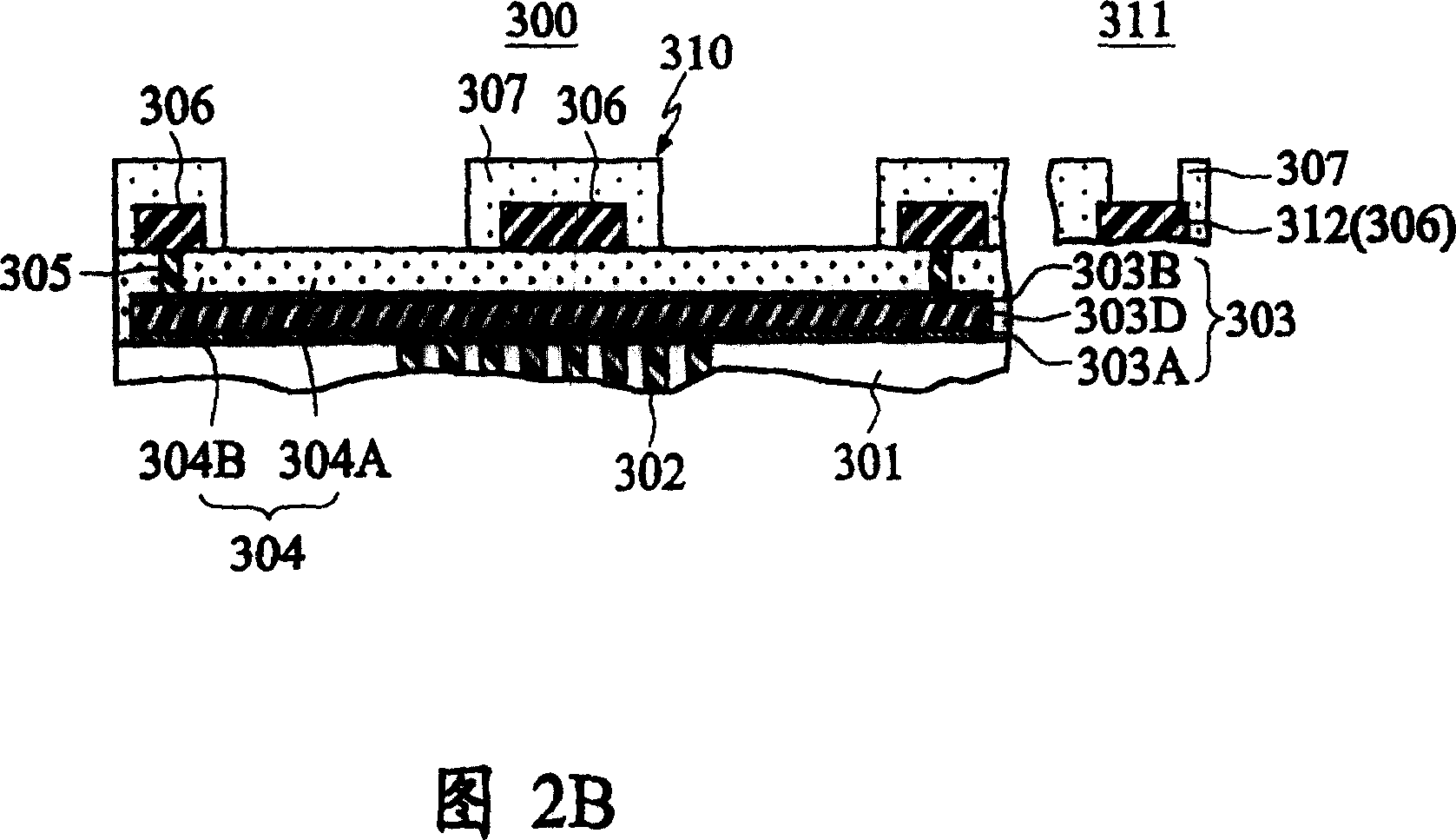

[0031] FIG. 1 shows a cross-sectional view of a capacitive pressure sensing element structure according to a preferred embodiment of the present invention.

[0032] As shown in FIG. 1, the capacitive pressure sensing element 20 of this embodiment includes a base layer 301, a fixed lower electrode plate 303A, a floating upper electrode plate 303B, a gap 303C, a first dielectric layer 304, a The upper metal composite layer 306 , a protection layer 307 , a plurality of etching holes 308 and sealing plug posts 309 .

[0033] A plurality of lower metal plug posts 302 and related circuit components are formed in the base layer 301 . The fixed lower electrode plate 303A is fixed on the base layer 301 and electrically connected to the lower metal plug posts 302 . The fixed lower electrode plate 303A is made of a titanium or titanium nitride material. Similarly, the floating upper electrode plate 303B is made of a titanium or titanium nitride material, and is suspended above the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com