Rare earth modified full non-lead X-ray screen rubber

A rare earth modification, X-ray technology, applied in shielding, reactor, nuclear engineering and other directions, can solve the problems of difficult to guarantee the uniform performance of material shielding, difficult to control the stability of material properties, easy to appear voids, etc., to achieve good interface compatibility , High dispersion interface compatibility, various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

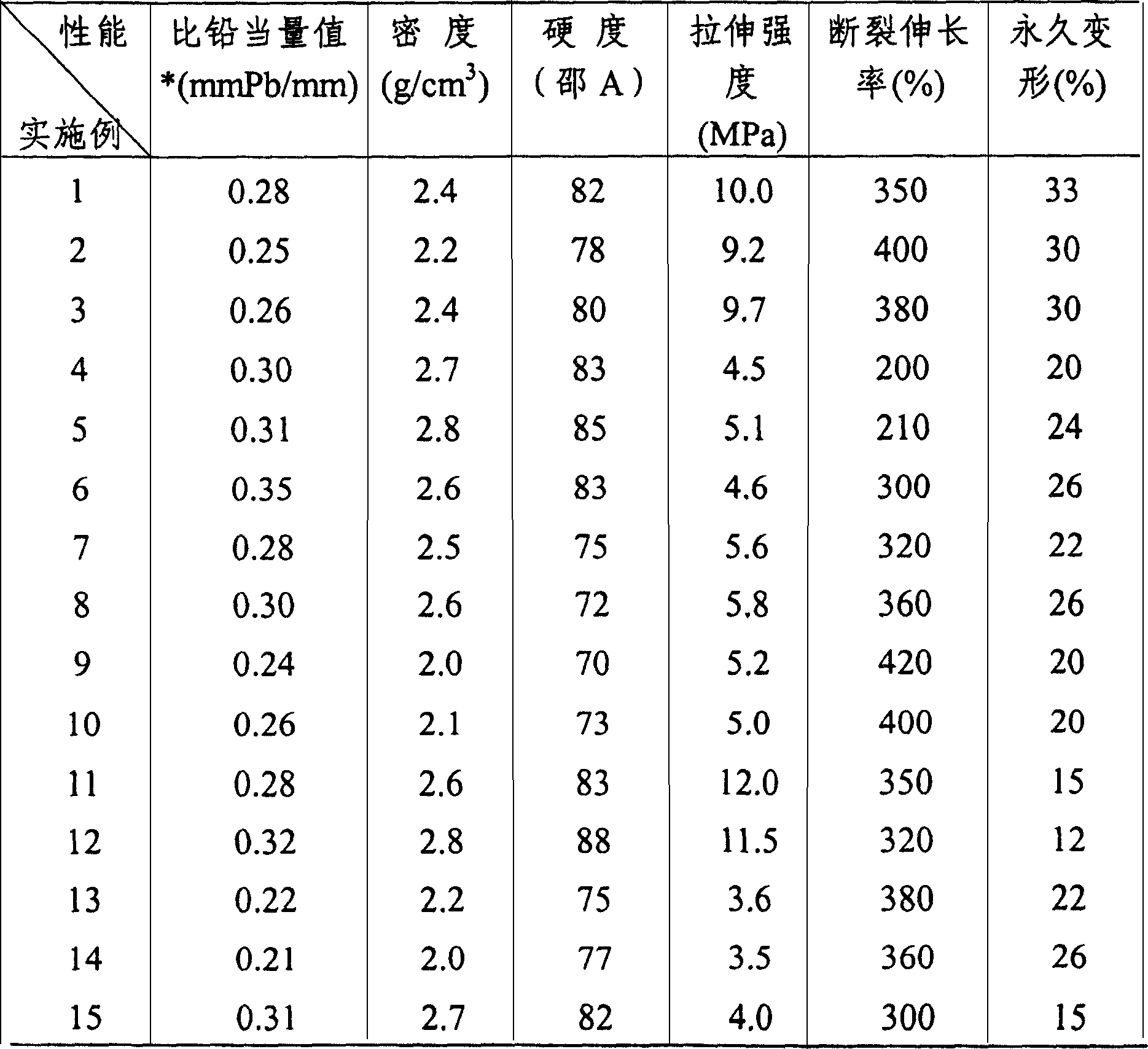

Embodiment 1

[0035] The composition and parts by weight of each component are:

[0036] Natural Rubber 100

[0038] stearic acid 2

[0039] Accelerator CZ 1.5

[0040] Gadolinium Acrylate 20

[0043] Gadolinium oxide 150

[0044] Si69 1.2

[0045] naphthenic oil 10

[0046] sulfur 3

[0047]Add 100 parts (parts by weight) of natural rubber to the internal mixer at normal temperature, and add 5 parts of zinc oxide and 2 parts of stearic acid in sequence at a rotor speed of 60-80 rpm at a shear rate, and mix for 1-2 minutes; Then add 1.5 parts of accelerator CZ and mix for 1-2 minutes; add 20 parts of gadolinium acrylate and 20 parts of neodymium acrylate in batches and mix for 5-8 minutes; add 150 parts of samarium oxide and 150 parts of gadolinium oxide in batches, and batch Add 10 parts of naphthenic oil, mix for 10-20 minutes, then add 1.2 parts of Si69, and mix for 2 minutes; finally, add 3 parts ...

Embodiment 2

[0049] The composition and parts by weight of each component are:

[0050] Natural Rubber 100

[0051] Zinc oxide 5

[0052] stearic acid 2

[0053] Accelerator CZ 1.5

[0054] Gadolinium Acrylate 20

[0055] Neodymium Acrylate 20

[0056] Neodymium oxide 150

[0057] Europium oxide 150

[0058] Si69 1.2

[0059] naphthenic oil 10

[0060] sulfur 3

[0061] Add 100 parts (parts by weight) of natural rubber to the internal mixer at normal temperature, and add 5 parts of zinc oxide and 2 parts of stearic acid in sequence at a rotor speed of 60-80 rpm at a shear rate, and mix for 1-2 minutes; Then add 1.5 parts of accelerator CZ, mix for 1-2 minutes; add 20 parts of gadolinium acrylate and 20 parts of neodymium acrylate in batches, and mix for 5-8 minutes; add 150 parts of neodymium oxide and 150 parts of europium oxide in batches, and batch by batch Add 10 parts of naphthenic oil and mix for 10-20 minutes, then add 1.2 parts of Si69 and mix for 2 minutes; finally, add ...

Embodiment 3

[0063] The composition and parts by weight of each component are:

[0064] Natural Rubber 100

[0065] Zinc oxide 5

[0066] stearic acid 2

[0067] Accelerator CZ 1.5

[0068] Europium acrylate 20

[0069] Samarium acrylate 20

[0070] Neodymium oxide 150

[0071] Terbium oxide 150

[0072] Si69 1.2

[0073] naphthenic oil 10

[0074] sulfur 3

[0075] Add 100 parts (parts by weight) of natural rubber to the internal mixer at normal temperature, and add 5 parts of zinc oxide and 2 parts of stearic acid in sequence at a rotor speed of 60-80 rpm at a shear rate, and mix for 1-2 minutes; Then add 1.5 parts of accelerator CZ and mix for 1-2 minutes; add 20 parts of europium acrylate and 20 parts of samarium acrylate in batches and mix for 5-8 minutes; add 150 parts of neodymium oxide and 150 parts of terbium oxide in batches, and batch by batch Add 10 parts of naphthenic oil and mix for 10-20 minutes, then add 1.2 parts of Si69 and mix for 2 minutes; finally, add 3 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com