Biological enzyme oil-displacing agent for increasing crude oil production rate and its oil displacing method

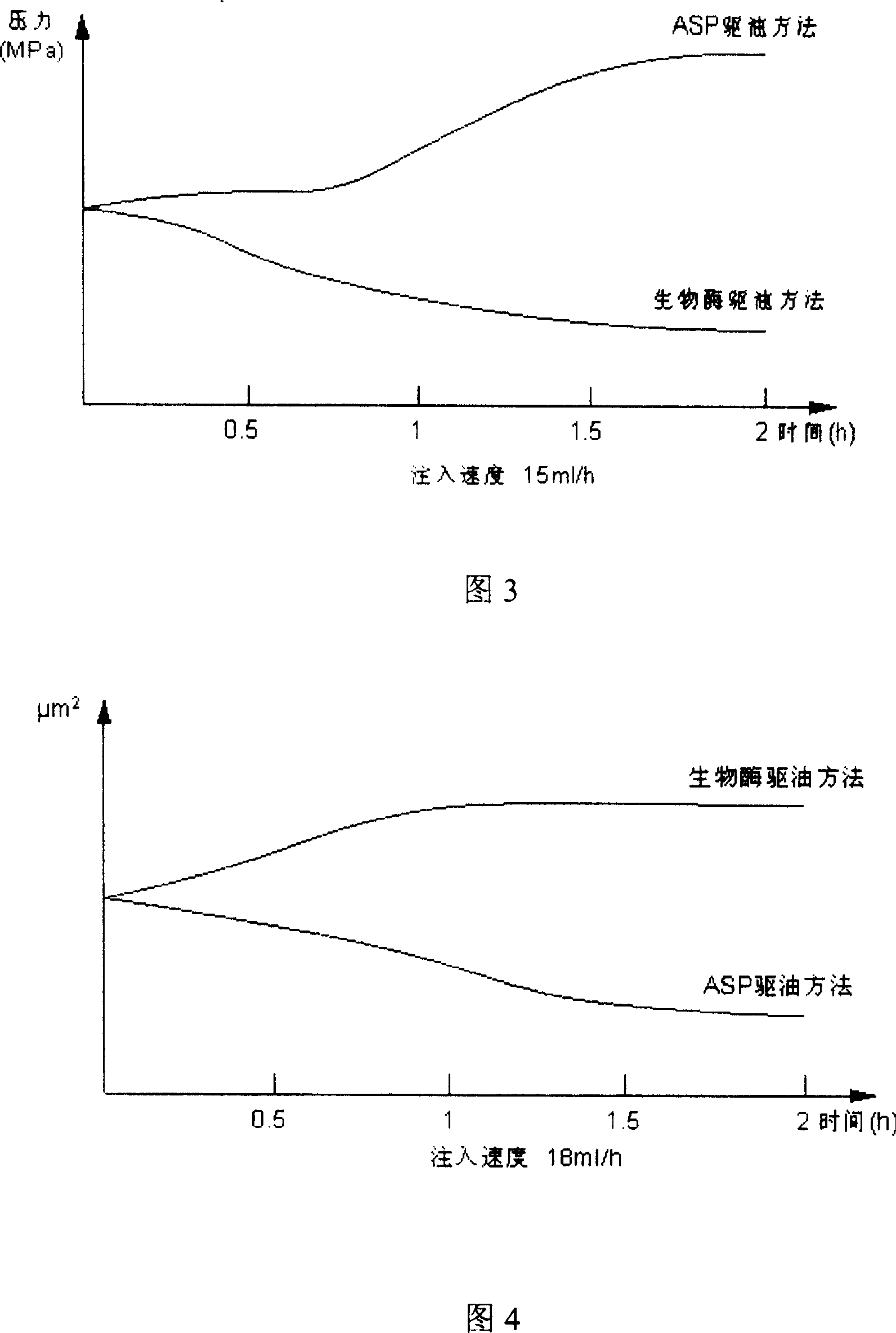

An oil displacement method and bio-enzyme technology, applied in drilling compositions, chemical instruments and methods, and production fluids, etc., can solve problems such as environmental and formation pollution, large temperature influence, and non-degradability, so as to improve water injection capacity, Prevent water damage and improve oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

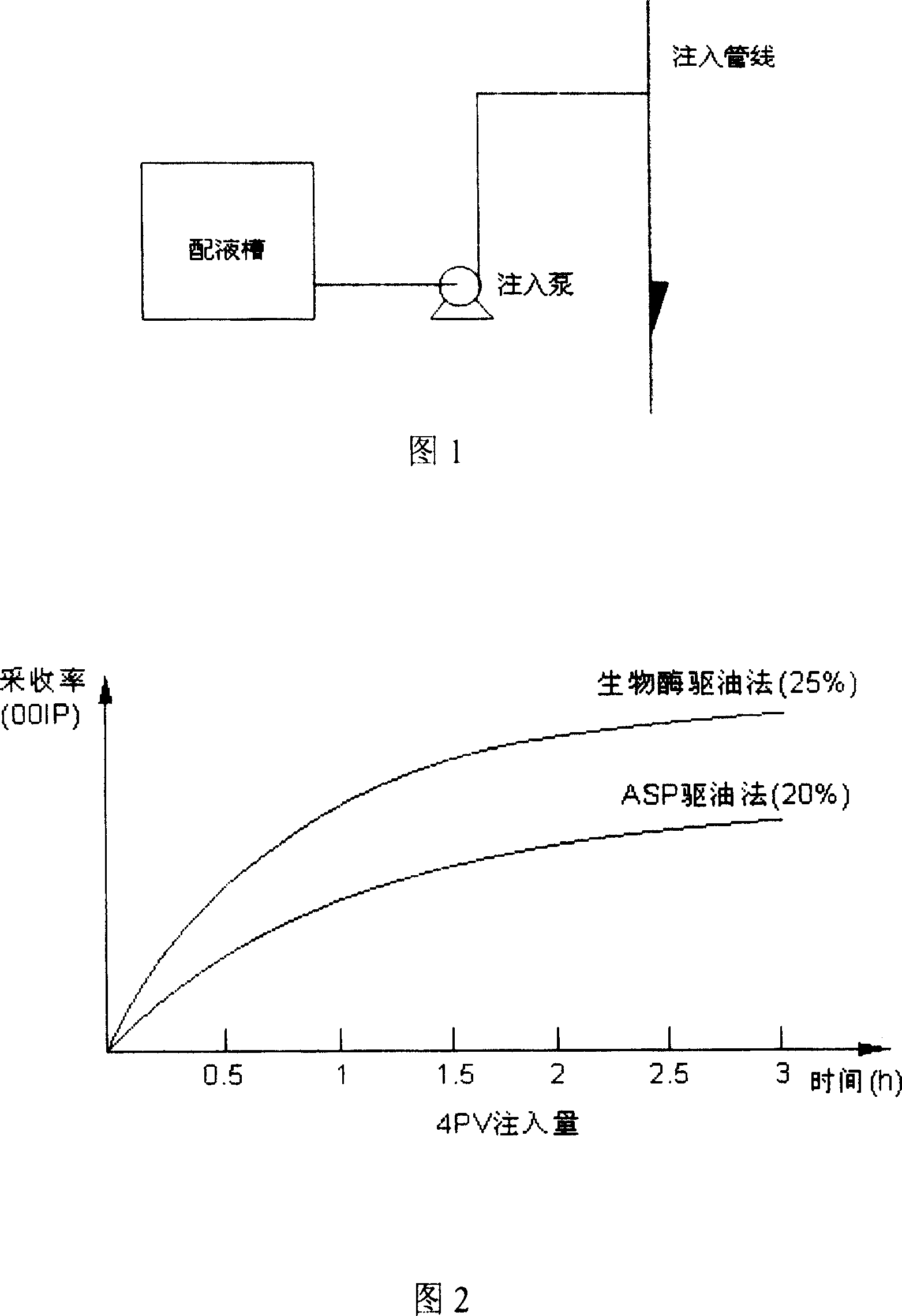

[0016] Example 1, 120 kg of biological enzymes, 40 kg of bis-quaternary ammonium salts, alkyl glycoside C 8~10 120 kg of APG and 720 kg of water are put into the liquid distribution tank, and injected into the formation by the injection pump through the injection pipeline.

Embodiment 2

[0017] Example 2, 200 kilograms of biological enzymes, kilograms of double quaternary ammonium salts 4, alkyl glycoside C 8~10 50 kg of APG and 746 kg of water are put into the liquid distribution tank, and injected into the formation by the injection pump through the injection pipeline.

Embodiment 3

[0018] Example 3, 160 kg of biological enzymes, 120 kg of bis-quaternary ammonium salts, alkyl glycoside C 8~10 4 kg of APG and 716 kg of water are put into the liquid distribution tank, and injected into the formation by the injection pump through the injection pipeline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com