Method and apparatus for grinding magnetic components and method and apparatus for treatment of waste liquid

A technology of grinding fluid and magnetic parts, applied in the direction of grinding/polishing safety devices, fine working devices, grinding/polishing equipment, etc., can solve filter clogging, grinding edge wear, and difficulty in effectively removing sediment and other issues to achieve the effect of easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, an embodiment of the present invention will be described with reference to the accompanying drawings.

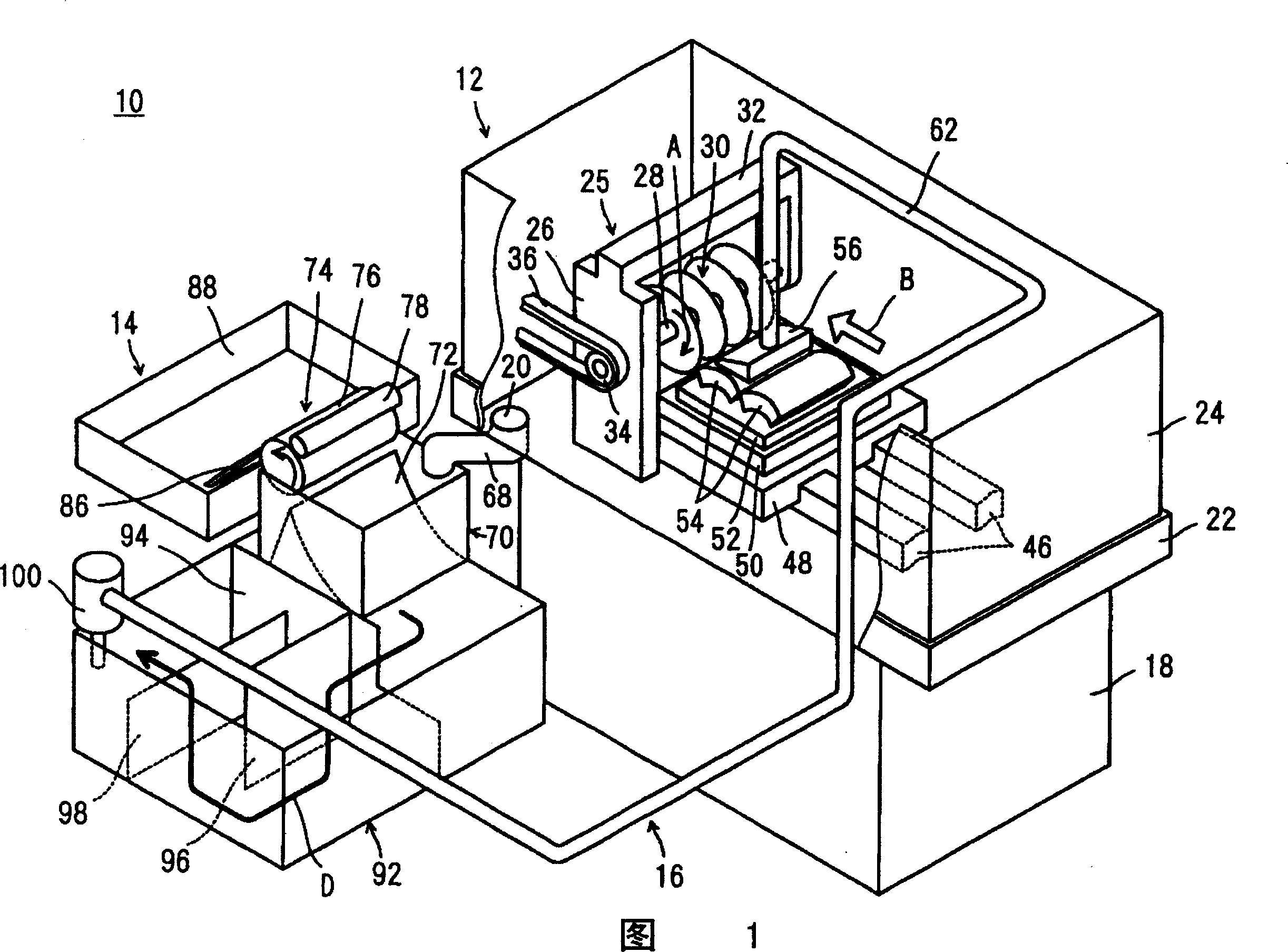

[0029] Referring to Fig. 1, as an embodiment of the present invention, the device 10 for grinding magnetic parts comprises a grinding operation part 12 for grinding magnetic parts 54 (will be described hereinafter), for by deposit 90 (It will also be described later) the purification part 14 for separating and purifying the grinding liquid 58 from the grinding liquid 58 used in the grinding operation part 12, and for retransmitting the purified grinding liquid 58 to the grinding operation Circulation section 16 of section 12.

[0030] The grinding operation part 12 includes a base 18 . The base 18 has an upper surface with an upwardly facing disc 22 having a drain 20 for discharging grinding fluid 58 thereon. The disc 22 has an upstanding plate 24 for preventing the grinding fluid 58 from splashing outside.

[0031] The disc 22 has an upper surface wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com