Steel wire drive scroll saw

A jig saw and steel wire technology, applied in the field of sawing machinery, can solve the problems of complex structure, complex shape, large vibration, complex processing technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

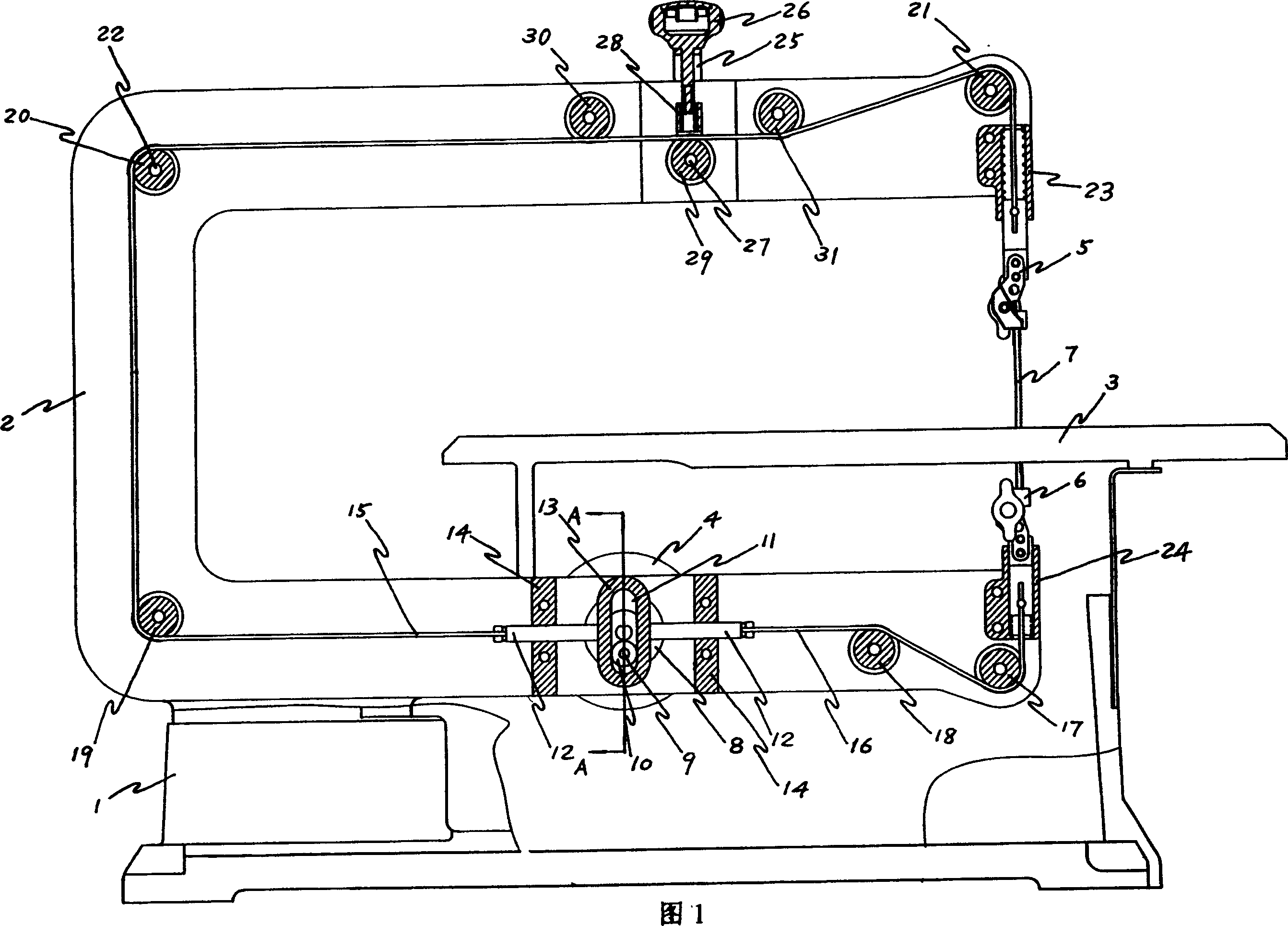

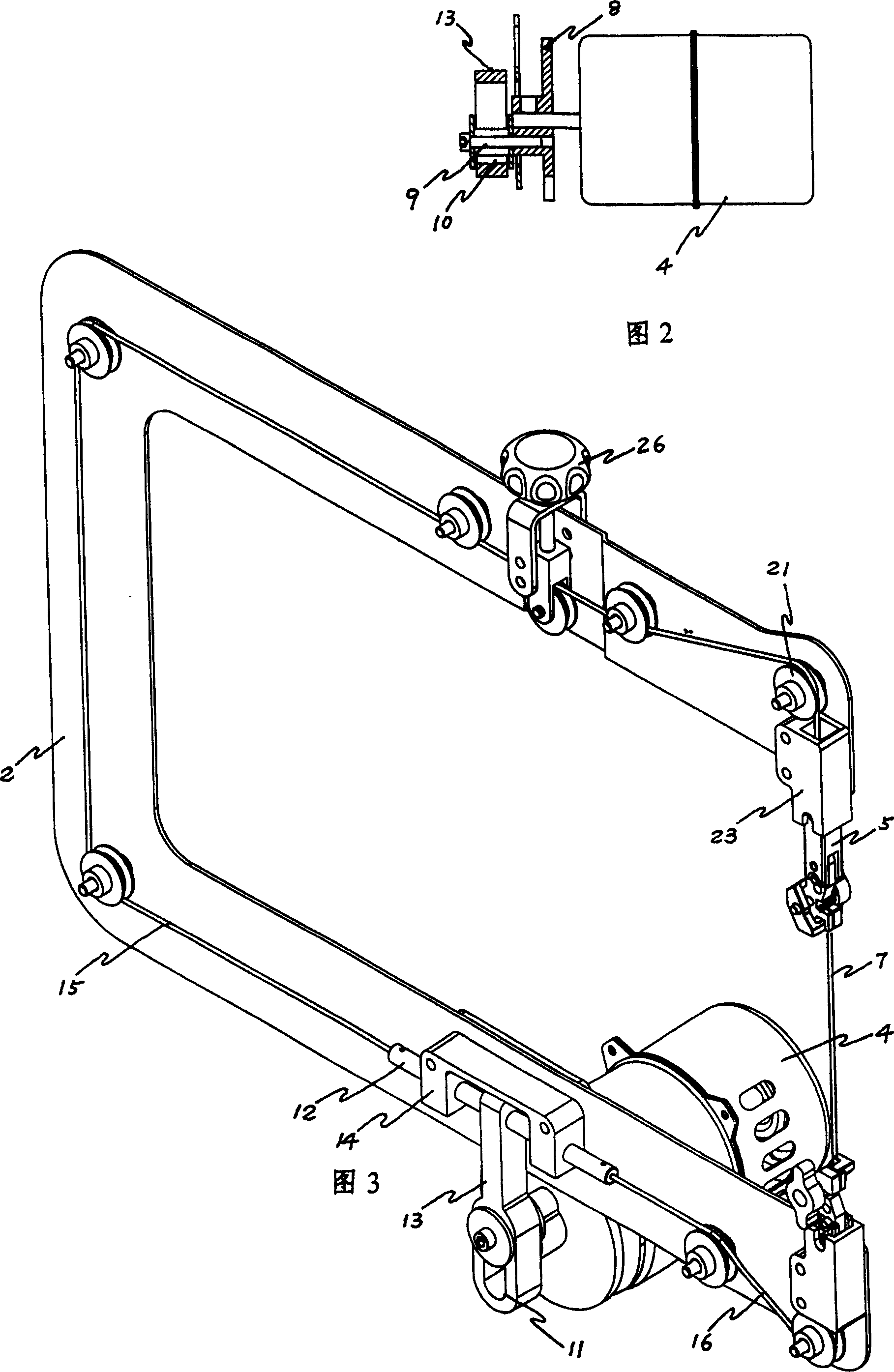

[0015] Example 1. A wire-driven jigsaw, as shown in Figures 1-2. It includes a base 1, a casing 2 installed on the base 1, a workbench 3 and a motor 4, upper and lower saw blade holders 5, 6 and saw blades 7 installed in the casing 2 and installed in the base 1 and the casing 2 transmission mechanism. The transmission mechanism consists of a flywheel 8 fixed on the shaft of the motor 4, a small shaft 9 eccentrically fixed on the flywheel 8, a roller 10 set on the small shaft 9, and a long groove 11 set on the roller 10 with left and right arms. The slide block 13 of 12, the guide block 14 fixed on the casing 2 with the left and right guide holes to be respectively sleeved on the left and right arms 12 of the slide block 13, the long steel wire 15 and the short steel wire fixedly connected to the two ends of the slide block 13 respectively 16. The guide wheel set installed on the casing 2, the upper and lower guide rails 23 and 24 with guide grooves installed on the casing 2,...

Embodiment 2

[0018] Example 2. A wire-driven jigsaw, the long steel wire and the short steel wire 16 are both made of steel wire ropes. The left and right arms 14 of the slider 13 are located at the upper end. All the other are with embodiment 1.

[0019] Embodiment 1 and Embodiment 2 have simple structure, good processing technology, small vibration and low noise during operation, and greatly reduce mold cost, material and processing cost. Its overall production cost is only a quarter of what it used to be. It can be widely used in the sawing of thin boards such as wood boards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com