Array type optical probe scanning IC photoetching method

A technology for scanning integrated circuits and optical probes, applied in chemical instruments and methods, circuits, optics, etc., can solve problems such as difficulty in reducing and increasing production costs, and achieve the effect of simplifying the production process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

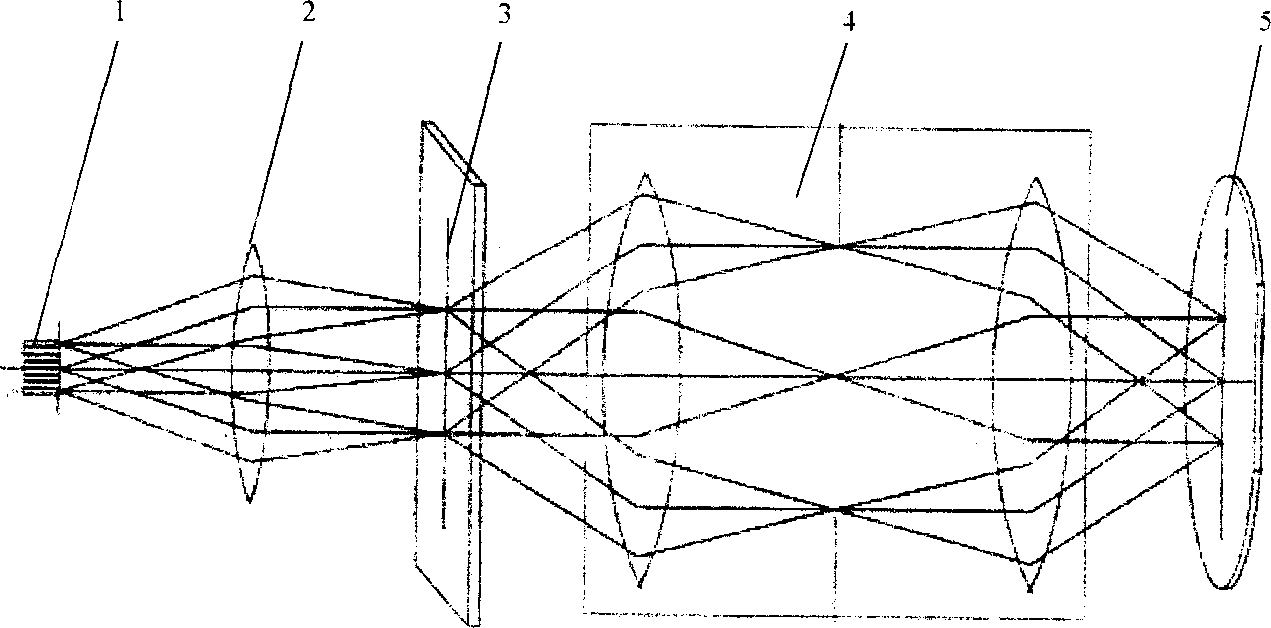

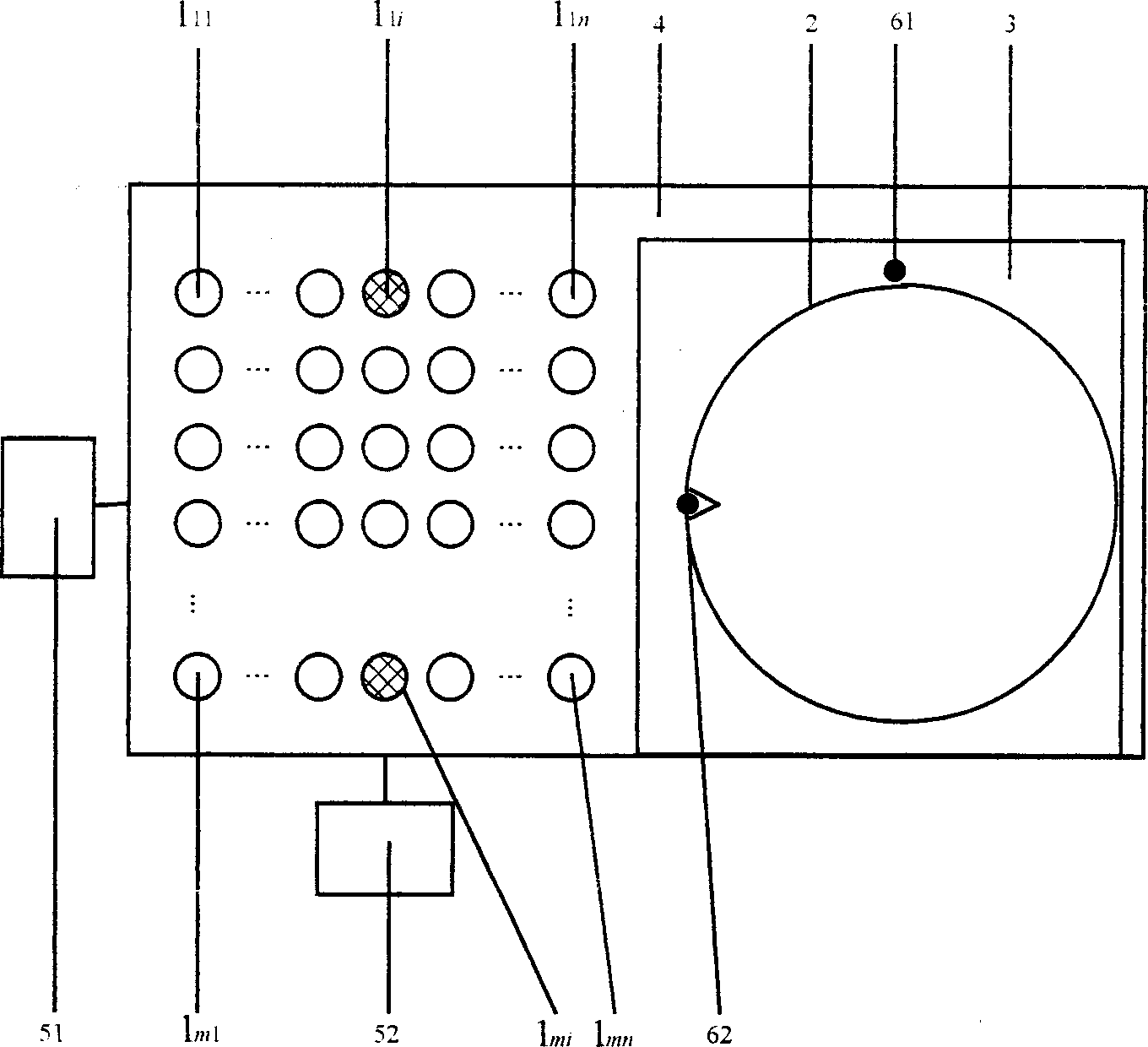

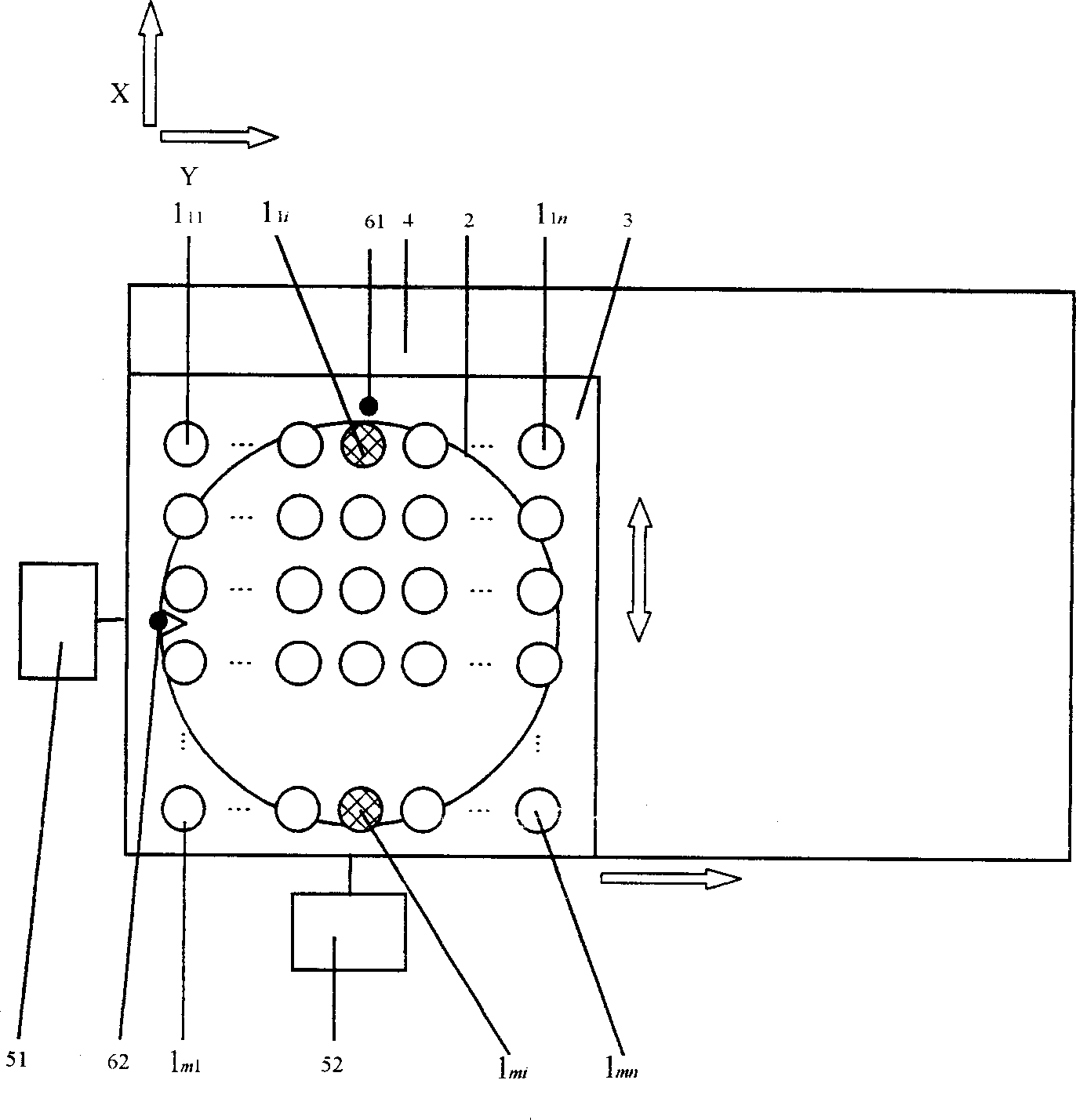

[0042] An embodiment of an array optical probe scanning integrated circuit lithography method proposed by the present invention is as follows figure 2 , 3 Shown, in conjunction with accompanying drawing, describe in detail as follows:

[0043] The optical probe array of this embodiment is a 40*40 square array formed by 1600 probe units, and its X-direction and Y-direction intervals can be adjusted by a computer. The adjustment range is 8mm-20mm, and the adjustment value is written according to the desired The size of the integrated circuit chip is determined. Probe unit 1 at the upper and lower ends li and 1 mi A unit for precise alignment in an array, with both read and write capabilities. When writing the circuit pattern, the movement and switching state of other units are the same. When performing precise alignment, they can read the signal on the silicon wafer, ensuring that the same silicon wafer is in a matching position every time it is written. whole unit 1 il ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com