Thermoplastic rubber composition

A thermoplastic, rubber technology, applied in the field of rubber matrix composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] Example 1-General steps for making composite materials

[0124] The following are general steps for manufacturing the composite material of the present invention. The amount of each component is given in the following specific examples.

[0125] Step: Pre-plasticize the natural rubber together with the first and second compatibilizers and peptizer (if necessary) in an internal mixer or open mill for about 5 minutes or less, although if open In the case of a mill, this process may take more than 10 minutes. The time depends on the viscosity of the rubber. The temperature during mixing or mastication should preferably not exceed 120°C. Any additives such as fillers can be added during the mastication process. After mixing, the raw materials are usually stable in viscosity, sliced and cured with the polyethylene flakes between the pieces. The curing time can be 6-12 hours. The rubber matrix is then cut into strips and added to a Branbury mixer or mixing extruder (such as a...

Embodiment 21

[0126] Example 2.1-Rubber thermoplastic composition containing nitrile first compatibilizer and polyamide thermoplastic

[0127] The composite materials listed in Table 1 were manufactured according to the steps of Example 1.

[0128] NR

NIR / N

BR

PA-6

PVA

Phenolic

Resin

Chlorination

Zinc acid

HVA 2

DCP

5

25

70

5

5

0.5

1

0.75

0.05

1

10

30

60

5

5

0.5

1

0.75

0.06

1

20

30

50

5

5

0.5

1

0.75

0.07

1

30

30

40

5

5

0.5

1

0.75

0.08

1

40

30

30

5

5

0.5

1

0.75

0.09

1

[0129] Ethylene rubber o...

Embodiment 22

[0131] Example 2.2-Rubber thermoplastic composition containing nitrile first compatibilizer and polyolefin thermoplastic

[0132] The composite materials in Tables 2 and 3 are manufactured below.

[0133] Shaw

NR

NBR

LLDPE

EVA

Engage

HVA 2

Peroxygen

Compound

MBTS

Zinc acid

65A

15

30

10

35

10

0.75

0.07

0.25

1

1

60A

15

30

10

30

15

0.75

0.07

0.25

1

1

55A

15

30

5

25

20

0.75

0.075

0.25

1

1

50A

15

30

5

20

25

0.75

0.075

0.25

1

1

45A

15

30

5

10

30

0.75

0.08

0.25

1

1

40A

15...

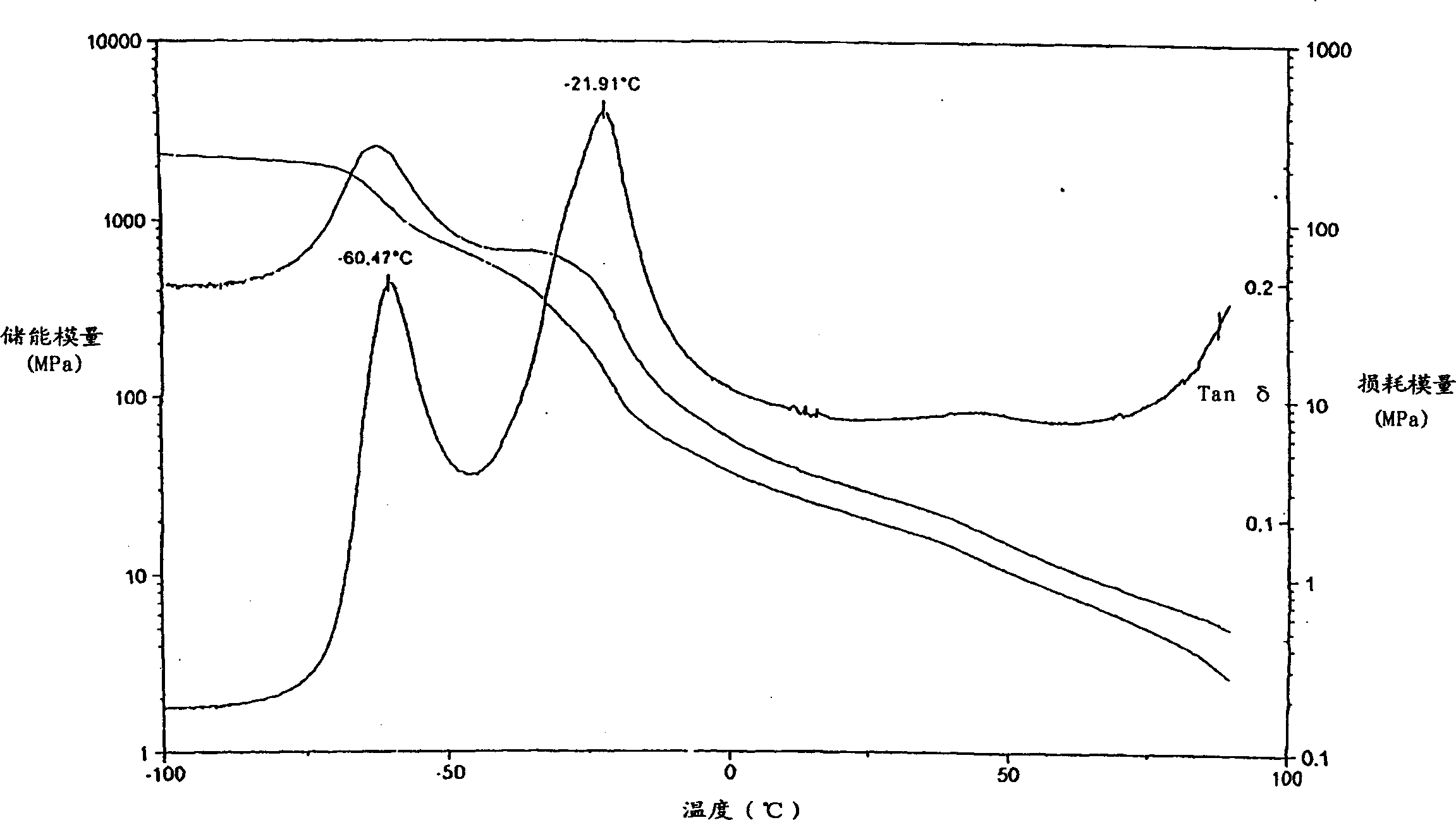

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com