Conductive nitride film, process for producing the same, and antireflection object

A technology of nitride film and conductivity, applied in the direction of non-metallic conductors, conductive layers on insulating carriers, sputtering plating, etc., can solve problems such as pressure changes, prolonged vacuum exhaust time, and reduced conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

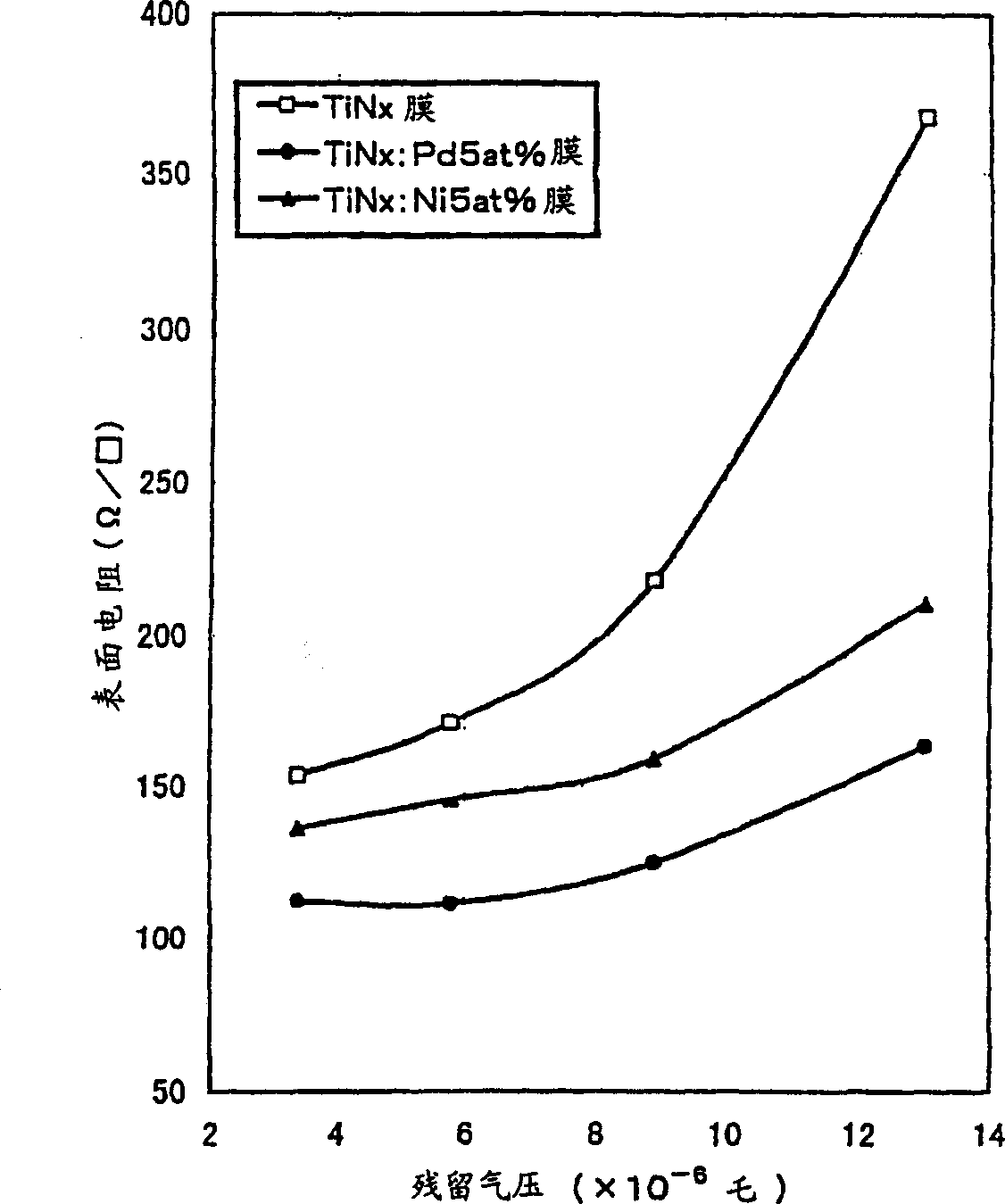

[0050] At a residual air pressure of 1.3 x 10 -5 Torr (1.73×10 -3 Pa) (approximately 5×10 -6 Torr (6.65×10 -4 Pa) is large, residual gas is large), Ar:N 2 =9:1 (volume ratio) mixed gas (6mm Torr (798mmPa)) atmosphere, at a power density of 2.2W / cm 2 Under the condition of , the Ti target containing Pd5at% (only Pd except Ti) is used to form a film on the glass substrate by the magnetron DC sputtering method. The obtained nitride film is a titanium nitride film (TiN x : Pd5at% film) with a film thickness of 20 nm.

[0051] The surface resistance (R s ), the difference in resistance between batches after 5 batches of film formation, and the change in resistance after heat resistance test (250°C, 30 minutes). The results are shown in Table 1.

Embodiment 2

[0053] Film formation was carried out in the same manner as in Example 1, except that the target used in Example 1 was replaced with a Ti target containing Ni 5 at % (only Ni in addition to Ti). The obtained nitride film is a titanium nitride film (TiN x : Ni5at% film), the film thickness is 20nm. The same measurement as in Example 1 was performed. The results are shown in Table 1.

Embodiment 3

[0055] A film was formed in the same manner as in Example 1 except that the target used in Example 1 was replaced with a Ti target. The obtained nitride film is titanium nitride film (TiN x film), the film thickness is 20nm. The same measurement as in Example 1 was performed. The results are shown in Table 1.

[0056] As can be seen from Table 1, with TiN x films compared to the inventive TiN x : Pd5at% film and TiN x : The difference in resistance between batches of Ni5at% film and the change in resistance after the heat resistance test are much smaller, and the repeatability and heat resistance are also very good.

[0057] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com