Embedded air inlet lip anti-icing heating assembly and manufacturing method

A technology for heating components and manufacturing methods, which are applied in aircraft parts, deicing devices, transportation and packaging, etc., can solve the problems of poor conformal curing, small contact area, difficult temperature control, etc. High measurement accuracy and good resistance repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The novel technical solution of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

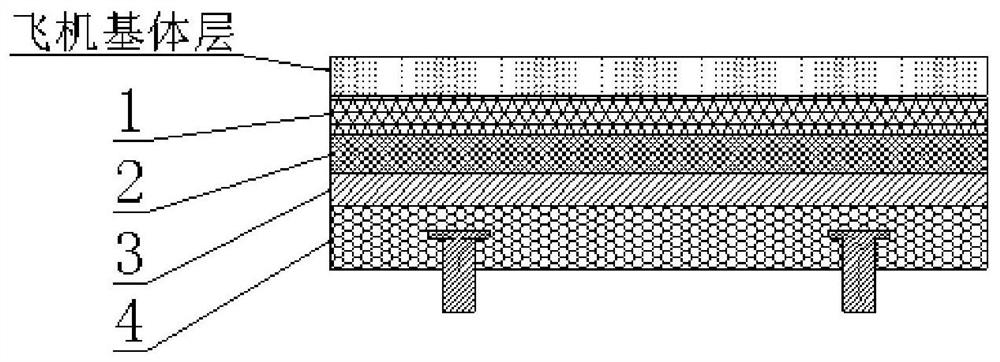

[0047] See attached Figure 1~6 As shown, an embedded air inlet lip anti-icing heating assembly includes a heating function unit (1), a temperature measurement function unit (2), an overcurrent protection unit (3), and an electrical connection unit (4);

[0048] A method for making an embedded air intake lip anti-icing heating assembly, the specific implementation includes the following steps:

[0049] Step 1: Make the heating unit(1)

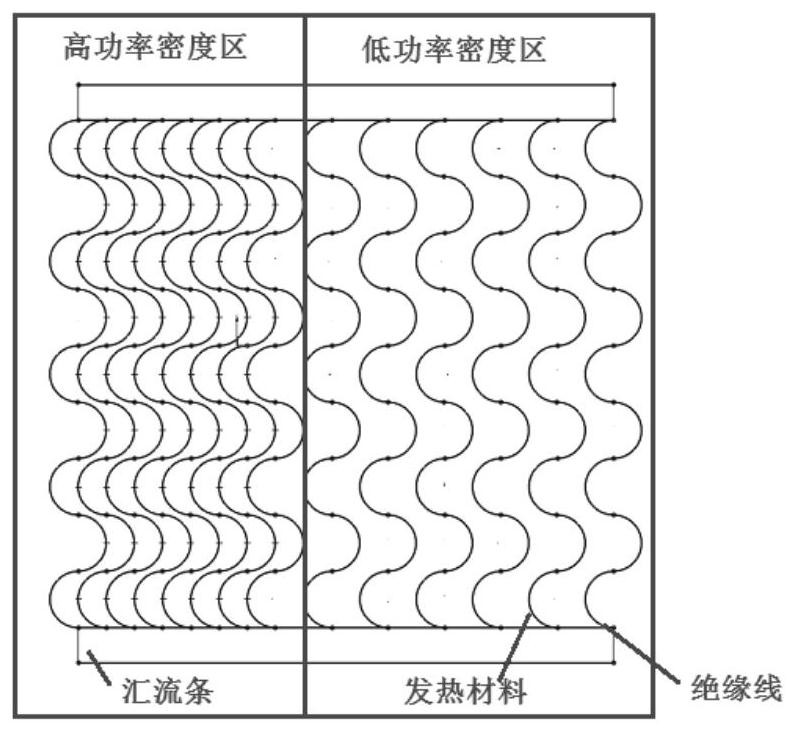

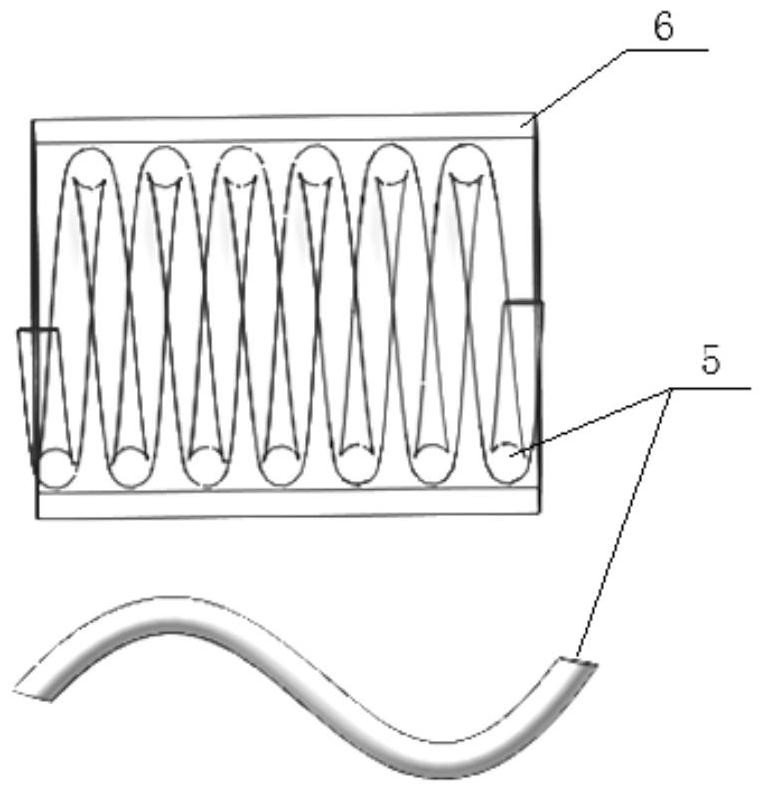

[0050] Use 30% carbon nano paper, 50% graphite, 10% paraffin, and 10% polypropionate to prepare conductive polymer (5), use 3D printing technology, print on polyethylene fiber, and then impregnate it in In the rubber solution of 9225 brand silicone, the rubber sheath (6) after curing is used as an insulating protective layer to make a flexible heating unit.

[0051] According to dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com