Method for obtaining woven fabric

A kind of craft and fabric technology, applied in the improvement of textile technology, in the field of fabrics with novel patterns, which can solve the problems of lost time, unsolvable, expensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

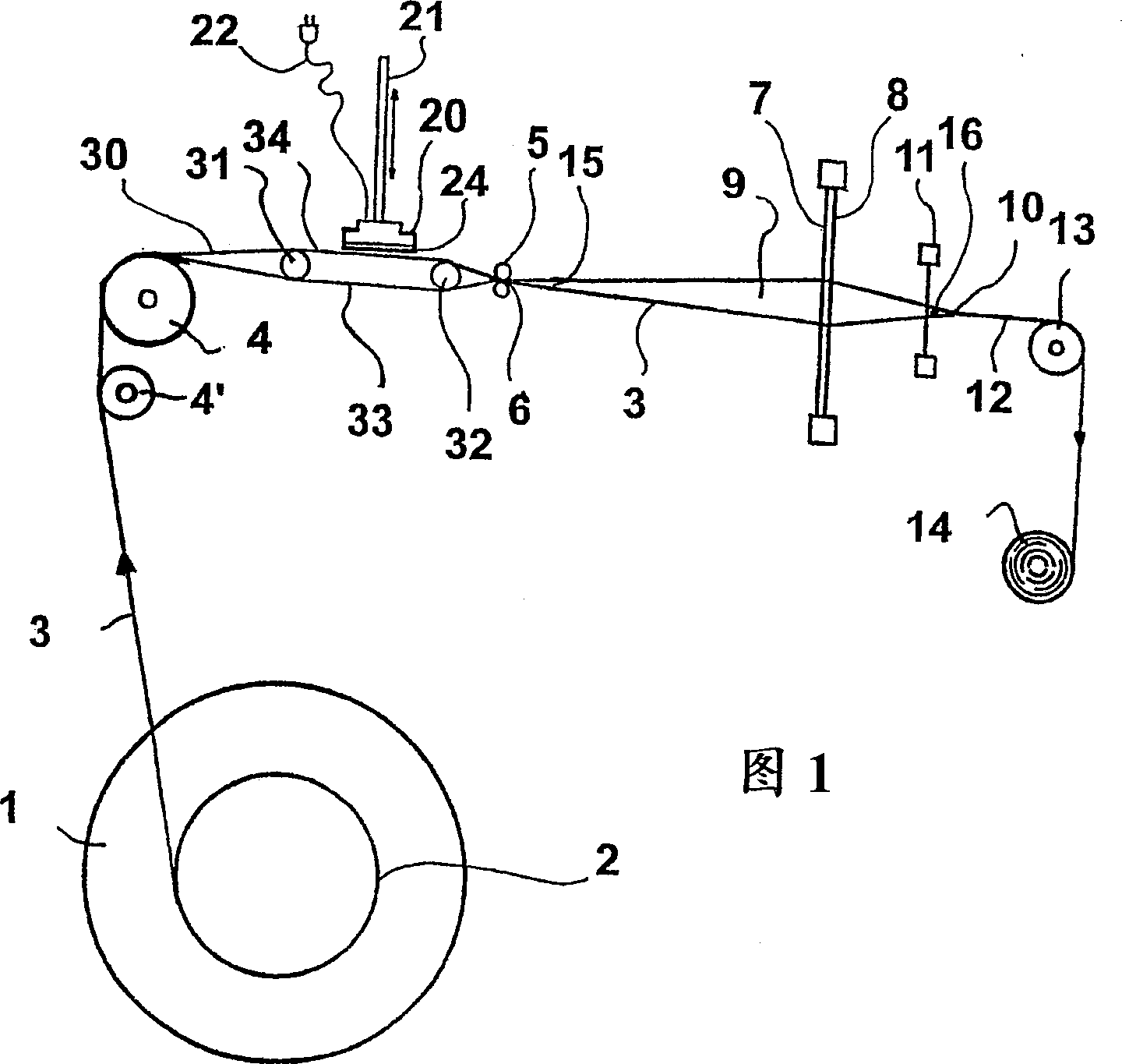

[0040]As mentioned above, the present invention relates to a textile process in which warp threads are treated differently. The process described has several applications, of which two main ones are the production of seersucker type fabrics and the production of striped fabrics. In the following, the production of seersucker type fabrics will be described first, followed by the production of striped fabrics. first implementation

[0041] In the first application, the textile process is applied to warp yarns, which generally have a higher modulus of elasticity.

[0042] The process can be employed on a conventional loom. Said loom should have means enabling the warp threads to be heat-treated while being tensioned by the take-up rollers of the loom, as described in French Patent No. 2751350.

[0043] Said weaving machine should also include specific components enabling the production of fabrics with the characteristics of the invention.

[0044] Thus, as shown in Figure 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com