Apparatus and process for monitor and control of ammoxiation reactor with fourier transform infrared spectrometer

A technology of infrared spectroscopy and reactors, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of not being able to provide at the same time, and achieve the effects of control improvement, real-time analysis and process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

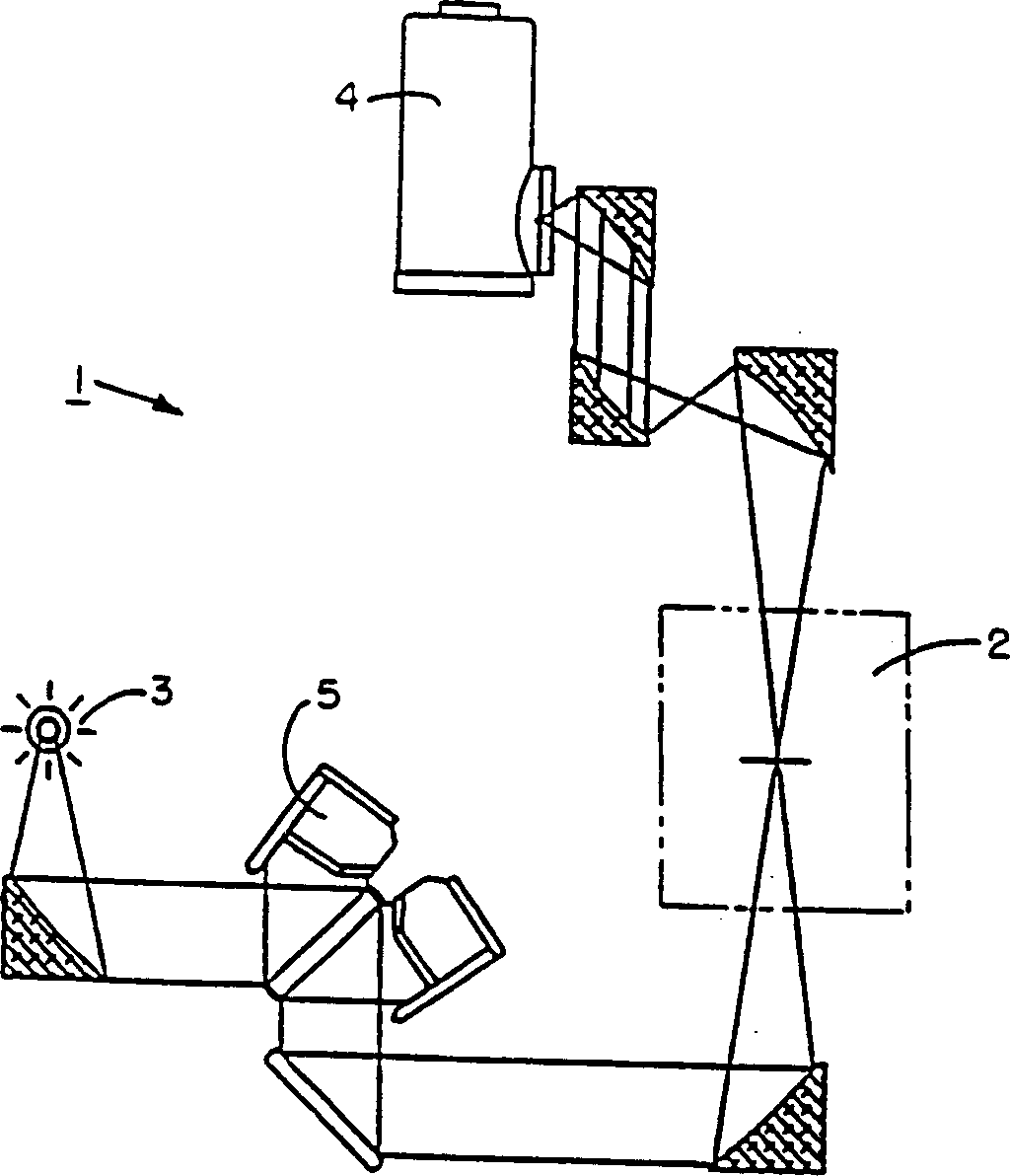

[0021] Fourier transform infrared (FT-IR) spectroscopy uses energy in the form of infrared (IR) radiation, which lies between the visible and microwave regions of the electromagnetic spectrum. figure 1 is a schematic diagram of the optics of an FT-IR spectrometer 1, for example for obtaining an IR spectrum of the combined effluent of an acrylonitrile reactor in accordance with the present invention. In one embodiment, figure 1 The FT-IR spectrometer shown schematically illustrates a BOMEM Michelson FT-IR spectrometer incorporating a Michelson interferometer. In the FT-IR spectrometer, a sample to be analyzed is placed in or passed through an FT-IR sample cell 2, which is specially designed to transmit light at infrared wavelengths. IR radiation emitted by a broad-spectrum infrared source passes through the sample cell 2 and travels to a sensitive IR detector 4 . The IR radiation emitted from the light source 3 is split by the interferometer 5 so that the IR radiation follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com