Decoration plate and its mfg. method, articles and time-pieces therewith

A manufacturing method and technology of decorative boards, applied in the field of decorations and clocks, can solve the problems of thick and noble, difficult to manufacture thin boards, increase the thickness, etc., and achieve the effect of beautiful appearance and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Embodiments of the present invention will be described below with reference to the drawings.

[0073] 1st form of implementation

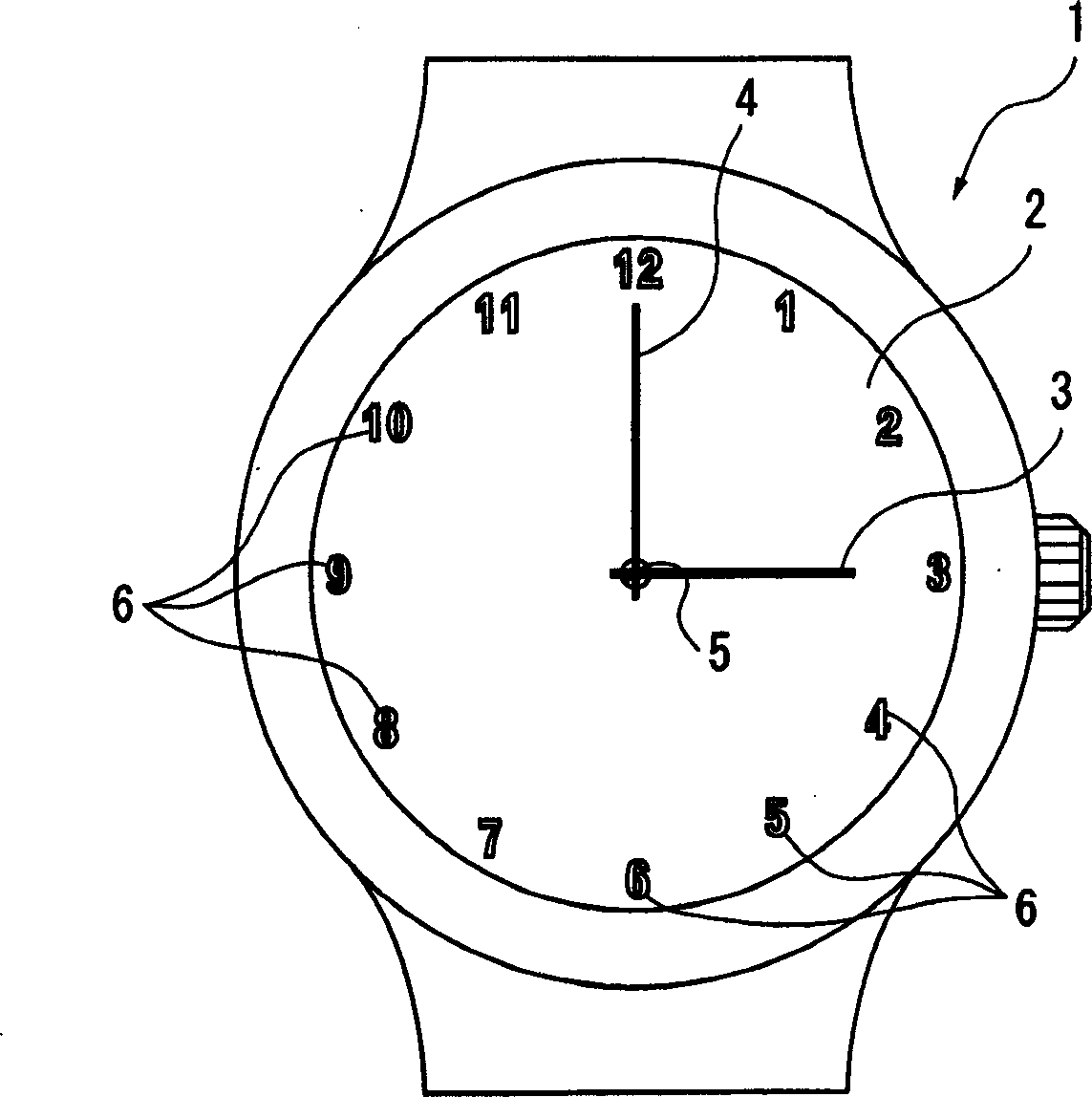

[0074] image 3 A timepiece 1 according to a first embodiment of the present invention is shown. This timepiece 1 is equipped with a dial 2 as a decorative plate of the present invention.

[0075] The center of the dial 2 is provided with a through hole 5 for passing the drive shaft of the hour hand 3 and the minute 4, the hour hand 3 is used to indicate the time, and the peripheral part of the dial has a plurality of time display parts 6 composed of printed numbers.

[0076] Dial 2 as Figure 4 As shown, the decorative groove 7 extending spirally from the inner side to the outer side is cut out on the entire surface, so that the entire surface becomes a decorative part.

[0077] Decorative slot 7 as Figure 5 As shown, the section forms a V shape.

[0078] Among the pair of hypotenuses that form a V on the inner part of the scroll of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com