Method and equipment of machining reducing deep hole with small mouth and large middle part

A processing device and processing method technology, applied in metal processing equipment, manufacturing tools, boring/drilling and other directions, can solve the problems of difficult processing, long processing cycle, high cost, and achieve simple and easy methods, high processing efficiency, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

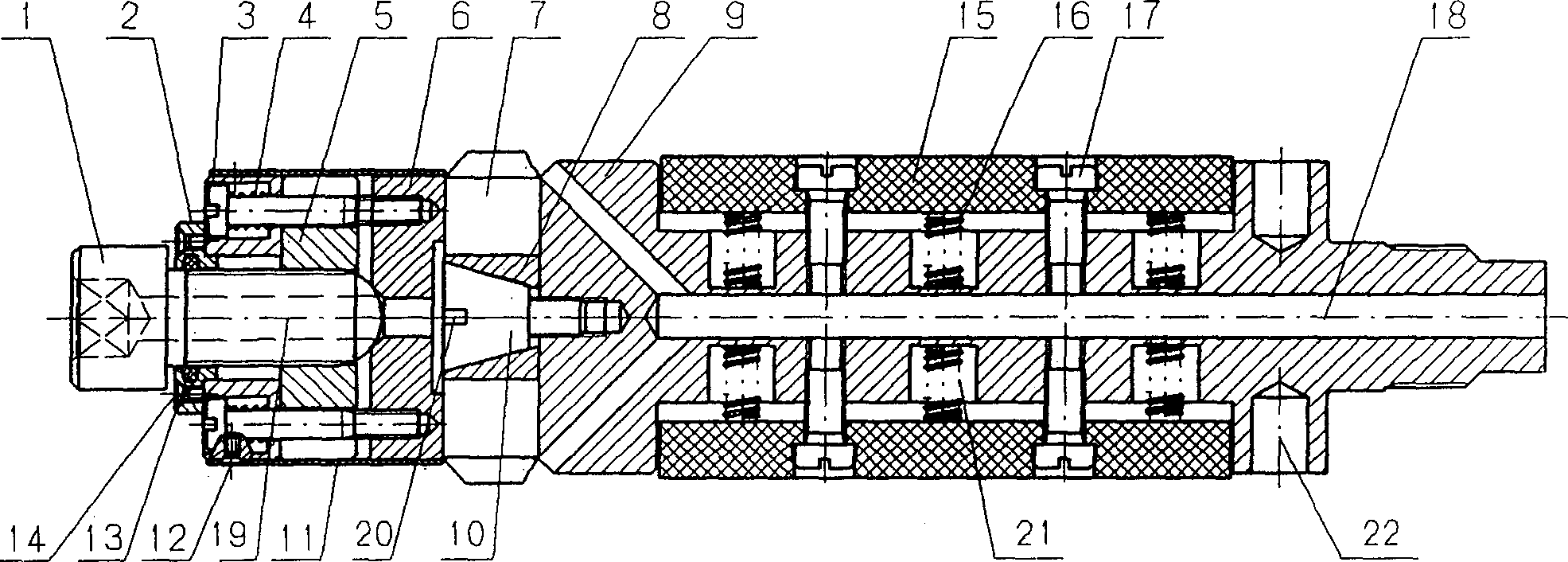

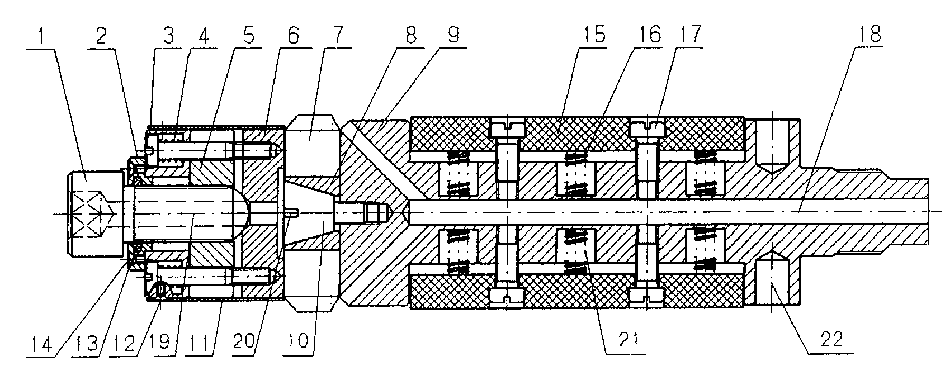

[0020] Refer to figure 1 , The boring device specially designed to implement the processing method of the variable diameter deep hole with a small entrance and a large middle diameter is composed of a boring head body 9, a cutter head adjustment mechanism, a guide centralizing bar 15, a compression spring 16, a countersunk screw 17, etc. The overall shape is cylindrical. The cutter head adjusting mechanism is located on the upper part of the boring head body 9, and it is mainly composed of the set screw 1, the pressure sleeve 2, the connecting screw 3, the pressure spring 4, the tightening nut 5, the pressure plate 6, the cutter head 7, the adjusting ring 8, and the adjusting cone. 10. The sheath 11, the sealing ring 13 and the like are constituted. At a certain distance from the top of the boring head body 9, a rectangular installation groove is machined downward along the axis. In the installation groove, an adjusting cone 10, an adjusting ring 8, a cutter head 7, a pressing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com