Penetration filter material and preparing method and use of said material

A filter material and activated carbon technology, applied in the field of permeation and filtration materials, can solve problems such as clogging of percolation irrigation systems, and achieve the effects of convenient maintenance, free disassembly and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 60 g of activated carbon, 8 g of vinyl acetate copolymer, 28 g of polypropylene, and 0.05 g of gold-layer molybdenum. Among them, the vinyl acetate copolymer and polypropylene are powders that pass 60 meshes. Put the activated carbon into the water, add the gold layer molybdenum, so that the metal molybdenum is completely immersed in the activated carbon, remove the water liquid, dry the activated carbon impregnated with the metal molybdenum, mix it with vinyl acetate copolymer and polypropylene powder thoroughly, and heat it. After the temperature is raised to about 100°C, the polymer is softened and bonded, the mixture is filled into the heated mold, and pressure is applied to fully compress the material. After the compressed mold is cooled, the molded material is removed from the mold Unload it. The made permeable filter material is then cut, polished and modified into a product. According to needs, the product can also be drilled or welded with plastic parts.

Embodiment 2

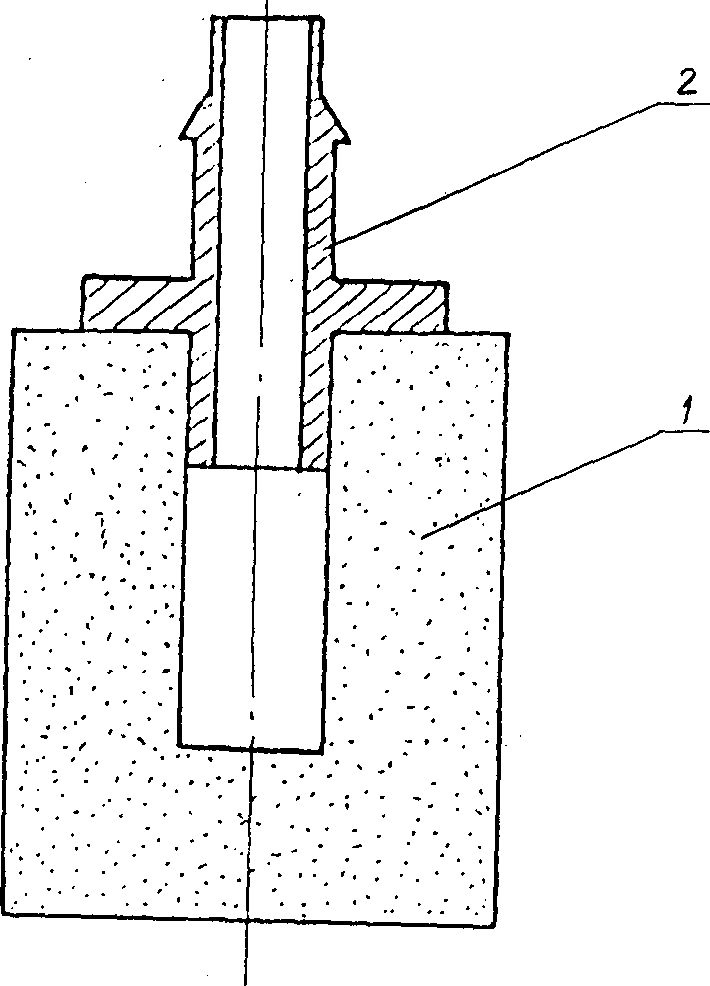

[0030] figure 1 It is an infiltration irrigation head made of permeable filter material. In the figure, a circular groove is drilled in the center of the cylindrical permeable filter material 1, and a plastic joint 2 is welded in the groove to form an infiltration irrigation head.

Embodiment 3

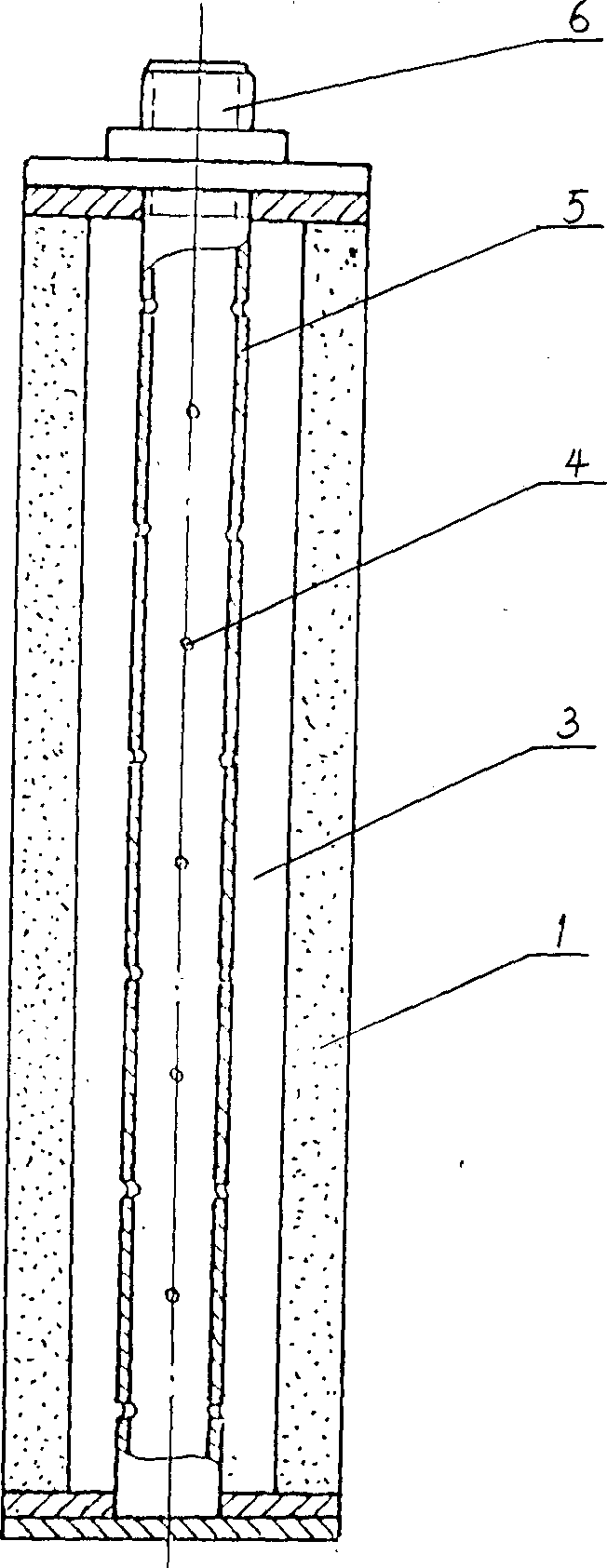

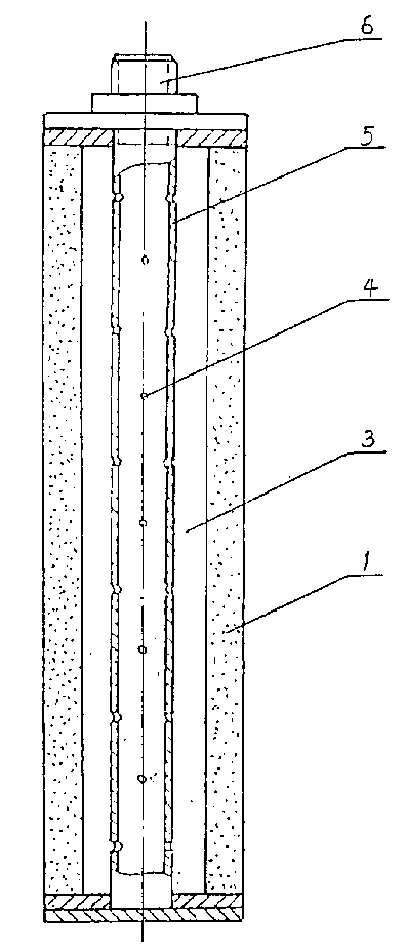

[0032] figure 2 It is a water filter made of permeable filter material. In the figure, the permeable filter material 1 is made into a hollow cylindrical shape, and the upper and lower ends are blocked. A core tube 5 is installed in the cavity 3 of the permeable filter material 1. A number of water outlets 4 are provided on 5, and the core tube 5 is connected with the water inlet 6 at the upper end of the permeable filter material 1. The water enters the core tube 5 from the water inlet 6 and flows into the cavity 3 through the water outlet 4, and is filtered by the permeable filter material 1 to obtain purified water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com