Method for preparing antiseptic agent

A preservative and piping technology, applied in chemical instruments and methods, lighting and heating equipment, components of steam boilers, etc., can solve problems such as water level control failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

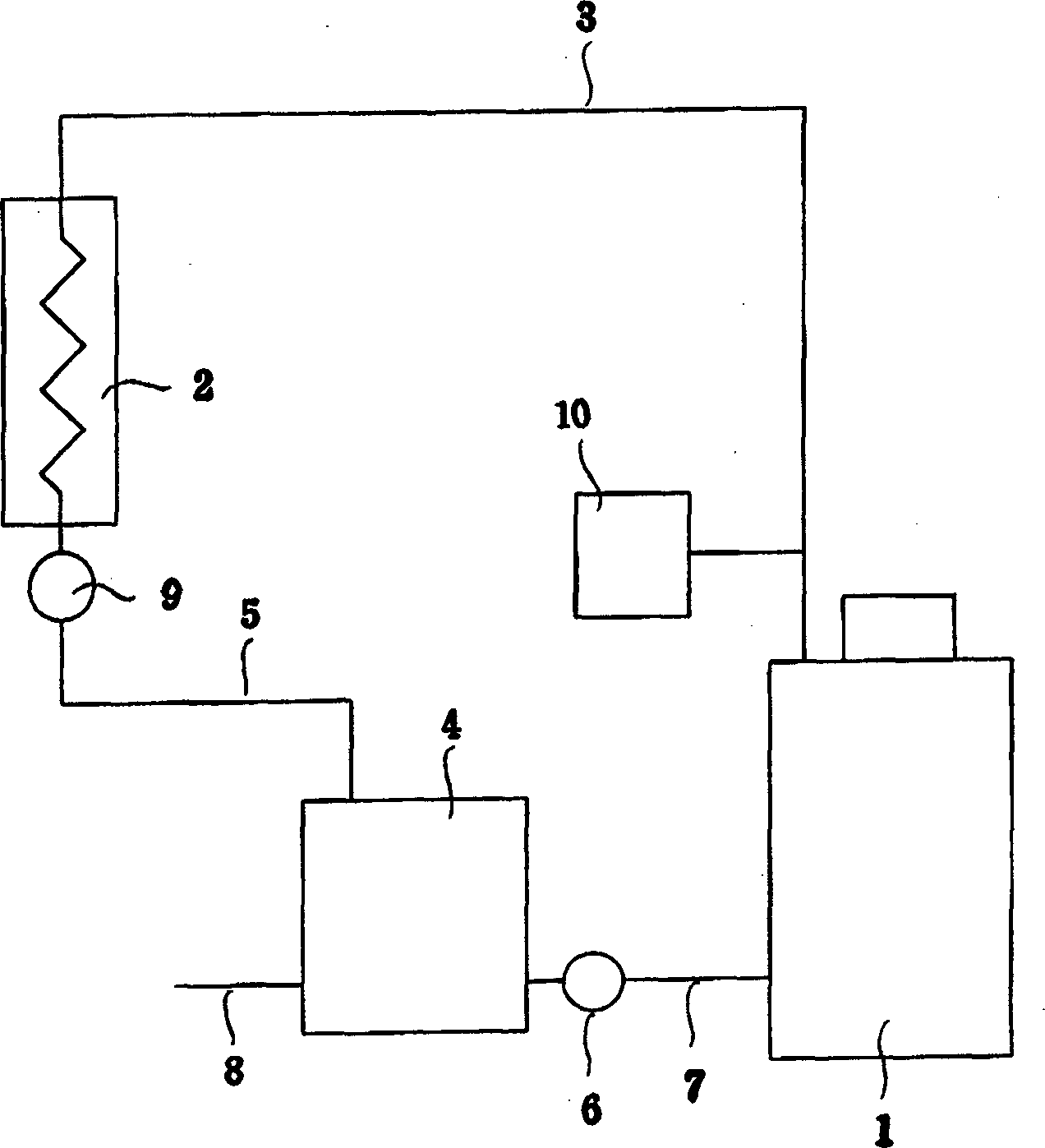

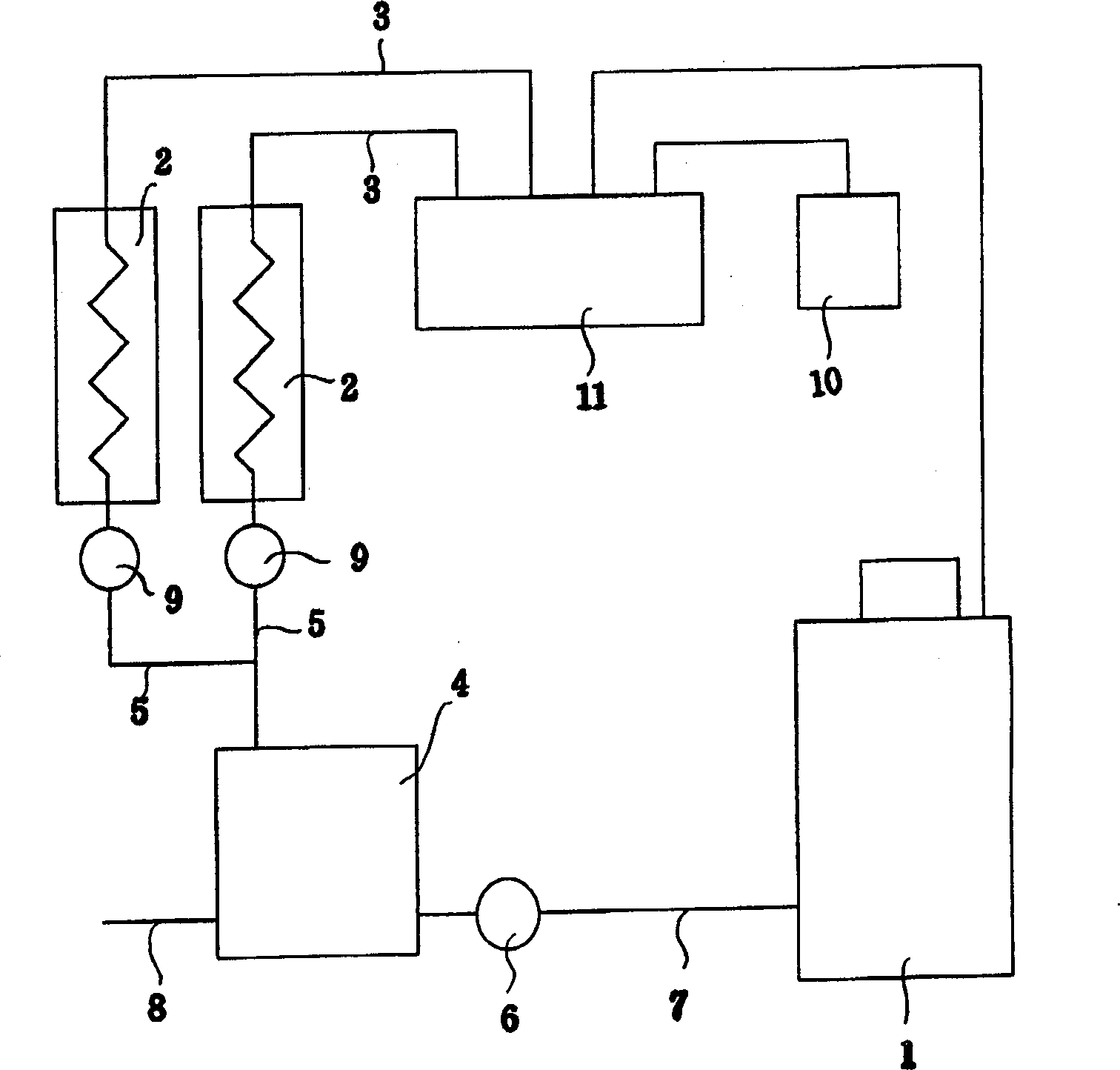

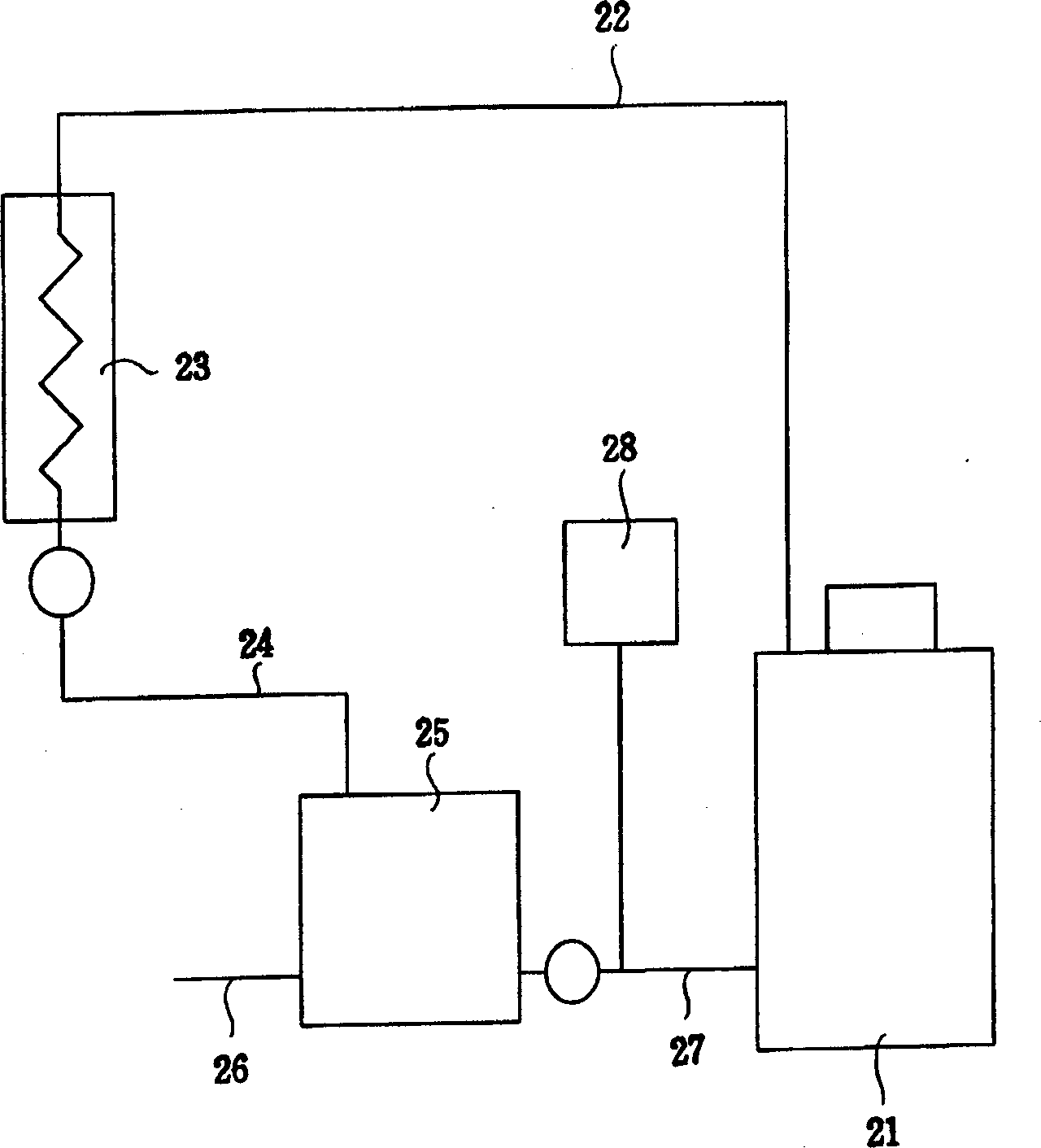

[0027] Hereinafter, specific examples of the present invention will be described. figure 1 It is an explanatory diagram schematically showing the structure of the first embodiment of the present invention. In addition, this is only an illustration and does not limit the scope of the present invention.

[0028] first, figure 1 Among them, the boiler 1 and the load equipment 2 are connected together through the steam pipe 3, and the load equipment 2 and the water supply tank 4 are connected together through the return water pipeline 5, and the lower part of the above water supply tank 4 and the above boiler 1 is connected by a water supply pump 6. The water supply pipes 7 are connected together. And in the said water supply tank 4, the supplementary water supplied from the raw water piping 8 and the return water supplied from the said return water piping 5 are mixed. Further, a steam trap 9 is provided on the return water pipe 5, and the steam and water are separated by the...

no. 1 example

[0034] Soft water is supplied to a small once-through boiler with an evaporation rate of 500kg / h at a pressure of 8kg / cm 2 It operates while continuously generating steam. Then, as a preservative, add 100 mg / liter (per liter of water supply) of 2-amino-2-methylpropanol to the steam piping (add 100 mg of preservative to the steam piping per liter of water supply) . At this time, the sample (mild steel 50 mm x 25 mm x 1 mm) was immersed in backwater, and the corrosion rate (mdd) was measured for 48 hours. The results are shown in Table 1. Here, the water used for the water supply is water softened from tap water in Matsuyama City, Aimei Prefecture. Furthermore, the water quality thereof is pH: 8.1, electrical conductivity: 250 μs / cm. M Alkalinity: 50mgCaCO 3 / Lift.

no. 2 example

[0036] Soft water is supplied to a small once-through boiler with an evaporation rate of 500kg / h at a pressure of 8kg / cm 2 It operates while continuously generating steam. Then, as a preservative, 100 mg / liter (per liter of water supply) of 2-amino-2-methylpropanol (100 mg per liter of water supply) was added to the steam trap preservatives). At this time, the sample (mild steel 50 mm x 25 mm x 1 mm) was immersed in backwater, and the corrosion rate (mdd) was measured for 48 hours. The results are shown in Table 1. Here, the water used for the water supply is water softened from tap water in Matsuyama City, Aimei Prefecture. Furthermore, the water quality thereof is pH: 8.1, electrical conductivity: 250 μs / cm. M Alkalinity: 50mgCaCO 3 / Lift.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Alkalinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com