Method and apparatus for retarding scale formation of water heating boiler by utilizing reflux dilution turbulence

A hot water boiler and boiler technology, applied in heat exchange equipment, lighting and heating equipment, damage protection, etc., can solve the problems of weak portability, single descaling function, poor economy, etc., to strengthen scouring and peeling, improve erosion The effect of low speed and running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

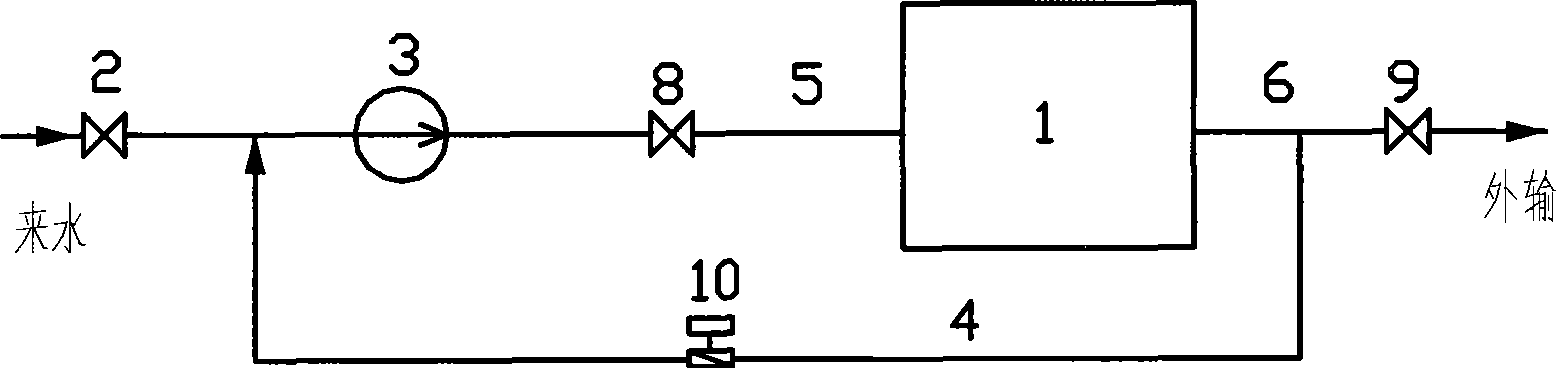

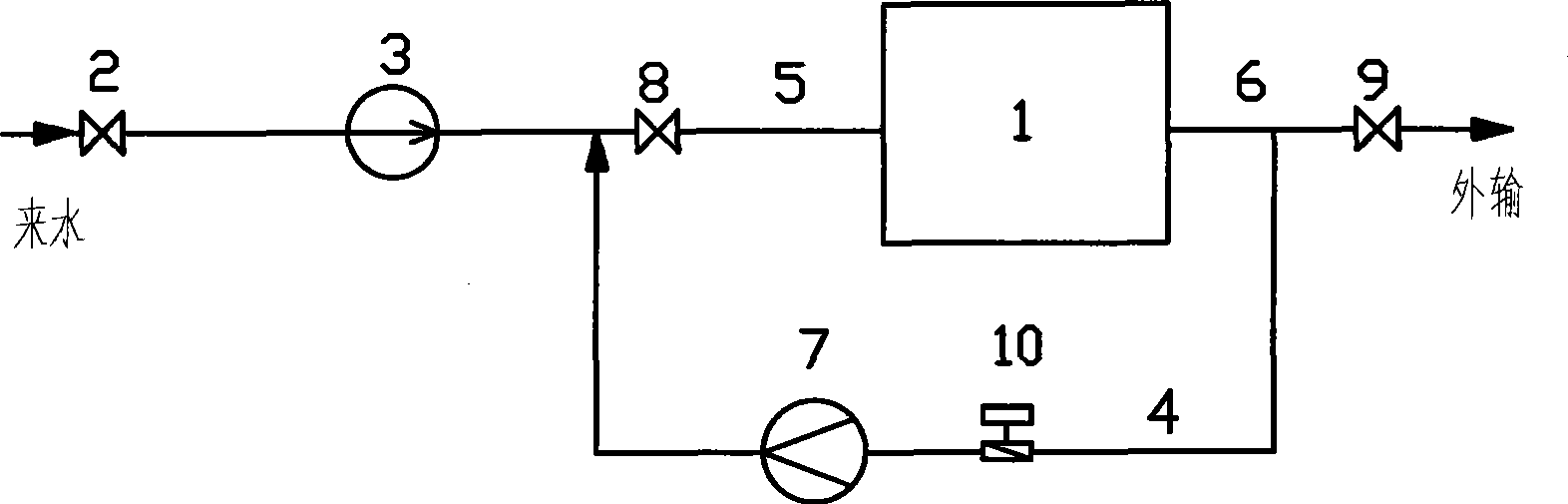

[0030] Such as figure 1 As shown, a return bypass pipe is added between the boiler inlet and outlet pipes, so that part of the boiler outlet water is circulated back to the boiler inlet to be mixed with new boiler inlet water and then heated and transported. Since the ion concentration in the high-temperature boiler outlet water is greatly reduced, When mixed with low temperature boiler inlet water:

[0031] (1) It dilutes the "raw water" at the boiler inlet and reduces the concentration of scaling ions in the fluid in the tube;

[0032] (2) The flow rate of water in the boiler tube is improved, the fluid scours and peels off the scale layer on the wall surface, improves the erosion rate of the scale layer, and reduces the deposition of the scale layer on the wall surface of the tube wall;

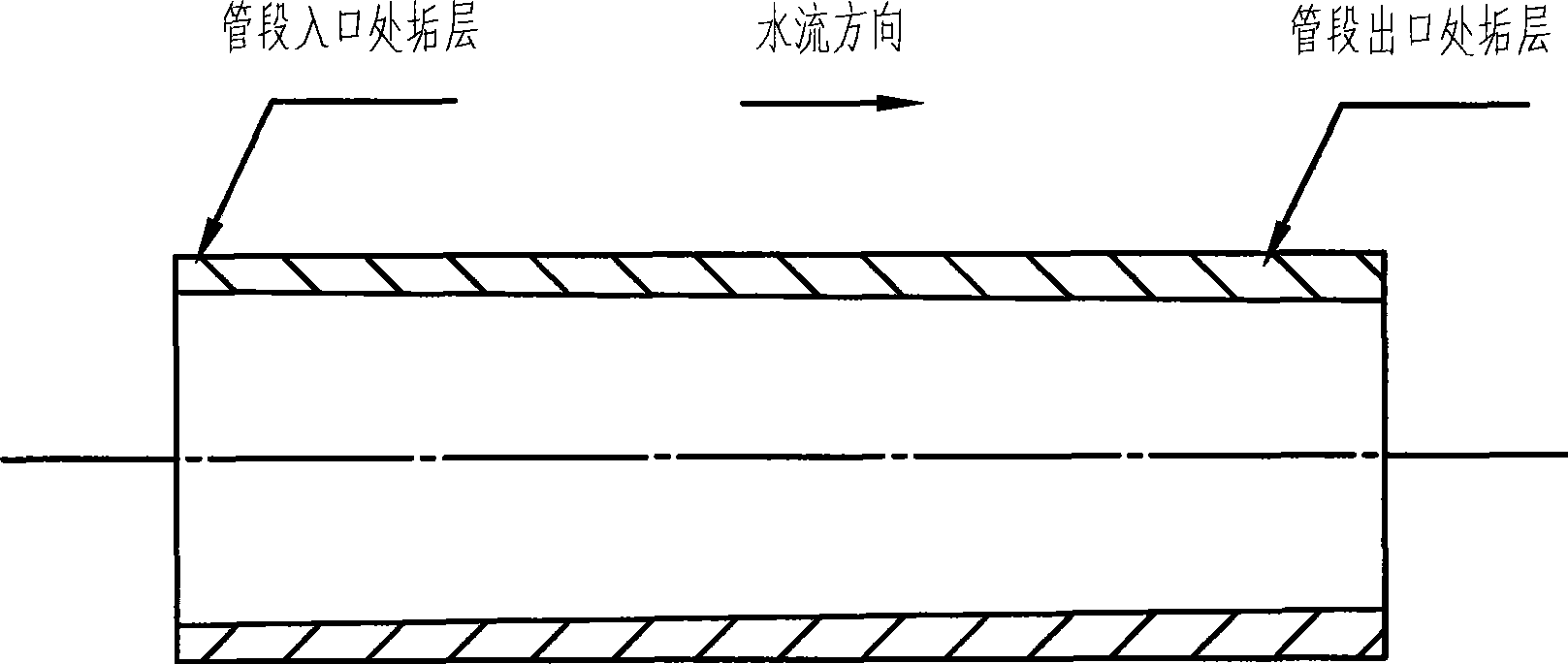

[0033] (3) The boiler inlet temperature rises, causing CaCO 3 Scale is deposited near the entrance of the pipe section in advance, which reduces the scale distribution in the back part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com