Boiler waste heat gradient utilization and deep water heat recovery system based on absorption heat pump

An absorption heat pump and boiler waste heat technology, applied in heat recovery systems, heating systems, heat pumps, etc., can solve the problems of lack of research and application, and achieve the effects of saving water resources, reducing environmental impact, and enhancing heating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

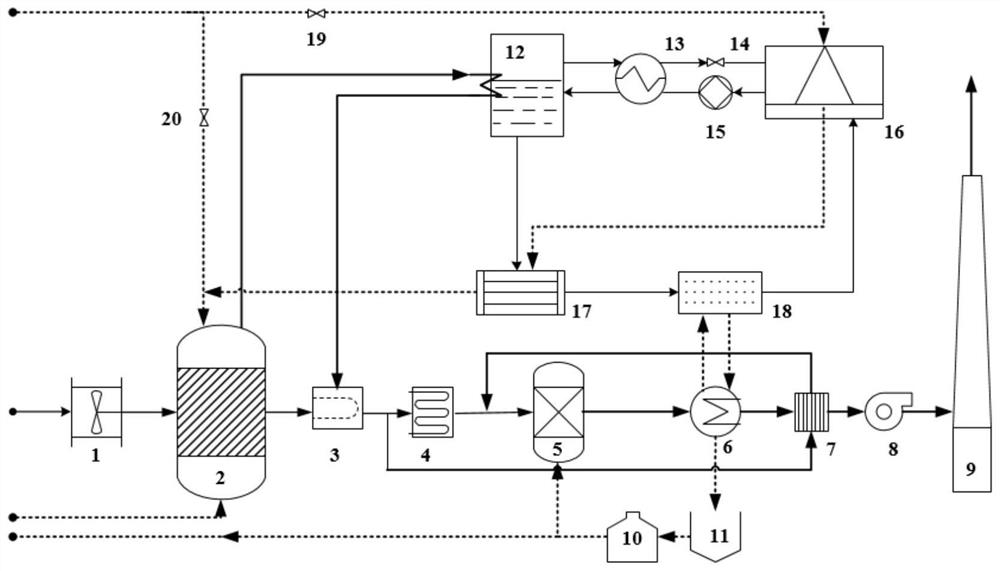

[0037] The absorption heat pump in this embodiment is single effect. Such as figure 1 As shown, the absorption heat pump is composed of a generator 12, a solution exchanger 13, a solution pump 15, a throttle valve 14, an absorber 16, a condenser 17, an evaporator 18 and connecting pipes. The blower 1 is connected to the boiler 2, and the flue gas generated by the boiler 2 is divided into two parts, one part of the flue gas enters the generator 12, and the other part of the flue gas enters the denitrification device 3. The flue gas flowing out from the denitration device 3 is divided into two parts, one part enters the low-temperature heating surface 4 and then enters the desulfurization device 5, and the other part enters the reheater 7, and then enters the desulfurization device 5 after exothermic cooling. After the desulfurization device enters the heat exchanger 6 to condense and release heat to form low-humidity dry flue gas, the high-temperature flue gas realizes double ...

Embodiment 2

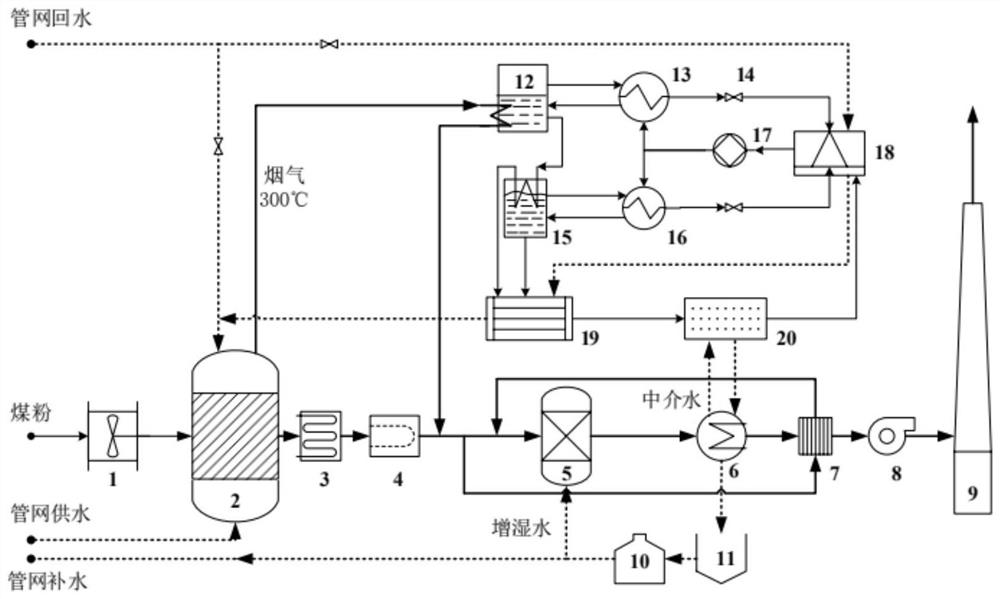

[0041] The absorption heat pump in this embodiment is double-effect. Such as figure 2 As shown, the absorption heat pump consists of a high-pressure generator 12, a high-temperature solution exchanger 13, a low-pressure generator 15, a low-temperature solution exchanger 16, a solution pump 17, a throttle valve 14, an absorber 18, a condenser 19, an evaporator 20 and Connecting pipes. The blower 1 is connected to the boiler 2, and the flue gas generated by the boiler 2 is divided into two parts, one part of the flue gas enters the high-pressure generator 12, and the other part of the flue gas enters the denitrification device 3. The flue gas flowing out from the denitrification device 3 is divided into two parts, one part enters the low-temperature heating surface 4 and then enters the desulfurization device 5, and the other part enters the reheater 7, and then enters the desulfurization device 5 after exothermic cooling. After the desulfurization device enters the heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com