Process for preparing low-alcohol or non-alcohol beverage from raw juice fermented wine

A technology for fermenting alcohol and fermenting wine, which is applied in the preparation of alcoholic beverages, beer brewing, biochemical equipment and methods, etc. problem, to achieve the effect of low alcohol concentration, low alcohol content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

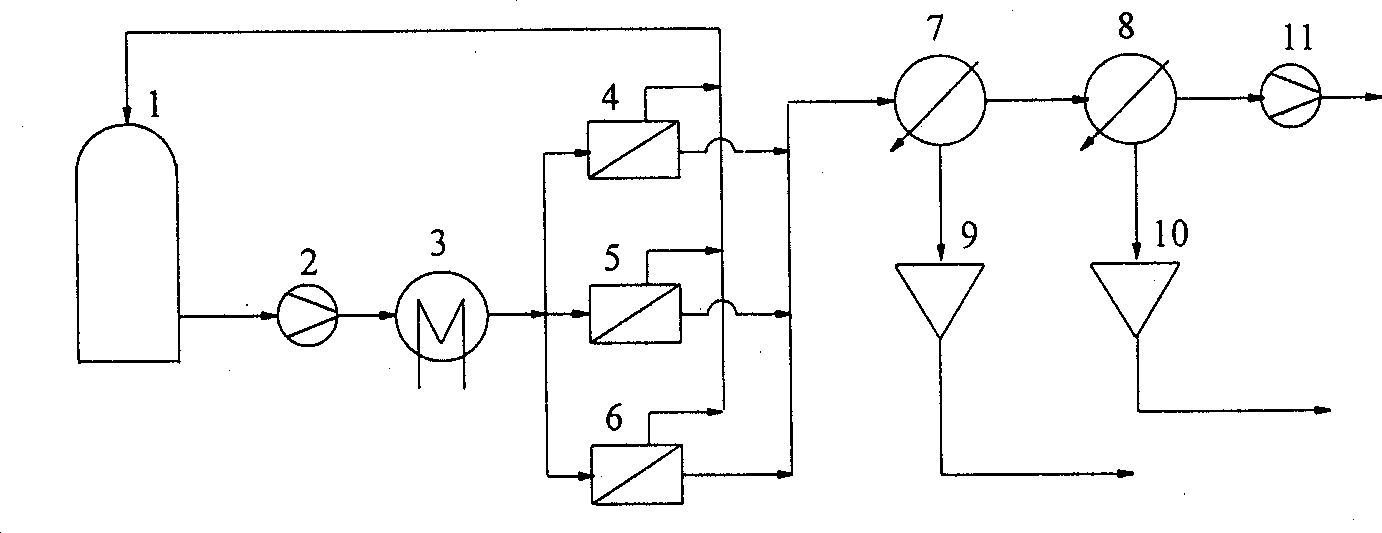

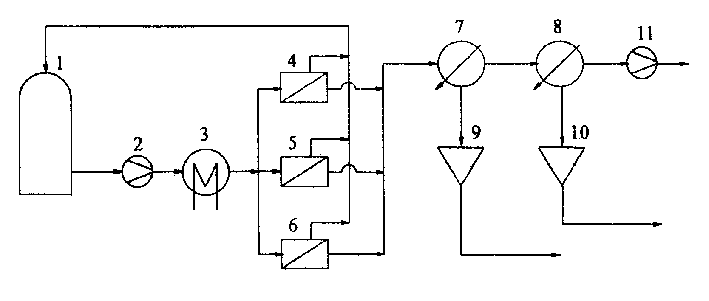

[0022] Embodiment 1: it is 0.024m with a silicone rubber composite membrane area 2 membrane components, press figure 1 According to the process, 3L of beer (Jinling brand, Nanjing Brewery) was taken and heated to 40°C for pervaporation dealcoholization, and the ethanol concentration of the original wine was > 3.7% (w / w). After 5 hours of circulation, the ethanol content in the beer was reduced to below 1%, and the volume was reduced to 2.6L. The high-boiling condensate contains about 20% ethanol, which accounts for most of the total permeate. A small amount of low-boiling condensate is returned to dealcoholized wine and replenished to a volume of 3L, and dry ice is added to supplement carbon dioxide loss. The appearance and color of de-alcoholized beer are exactly the same as the original wine, and the taste is almost exactly the same as the original wine. The condensate with high ethanol content is colorless and transparent, and tastes like distilled liquor with a strong b...

Embodiment 2

[0023] Embodiment 2: same as the method of embodiment 1, get dry red wine (Changyu dry red, Yantai Changyu Company) 3L and heat to 40 ℃ and carry out pervaporation dealcoholization, former wine ethanol concentration 12% (V / V) or 9.2% ( W / W). After / 8 hour cycle, the wine ethanol content was reduced to 5.5% (V / V), and the volume was reduced to 2.5L. The high-boiling condensate contains more than 40% ethanol, accounting for most of the total permeate. A very small amount of low-boiling condensate is returned to the de-alcoholized wine, and pure water is added to the original volume of 3L. The appearance and color of de-alcoholized wine are exactly the same as the original wine, and the taste is almost the same as that of the original wine. The condensate with high ethanol content is colorless and transparent, and tastes like distilled spirits with a strong wine aroma.

Embodiment 3

[0024] Embodiment 3: same as the method of embodiment 1, get dry red wine (Changyu dry red, Yantai Changyu Company) 3L and heat to 40 ℃ and carry out pervaporation dealcoholization, former wine ethanol concentration 12% (V / V) or 9.2% ( W / W). After a 12 hour cycle, the ethanol content of the wine was reduced to 3.2% (V / V) and the volume was reduced to 2.4L. The high-boiling condensate contains more than 37% ethanol, accounting for most of the total permeate. A very small amount of low-boiling condensate is returned to the de-alcoholized wine, and pure water is added to the original volume of 3L. The appearance and color of de-alcoholized wine are exactly the same as the original wine, and the taste is almost the same as that of the original wine. The condensate with high ethanol content is colorless and transparent, and tastes like distilled spirits with a strong wine aroma.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com