Ag-carried multifunctional tourmalinite fibre and its preparing process

A manufacturing method, tourmaline technology, applied in wet spinning, etc., can solve problems such as single function, insufficient performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

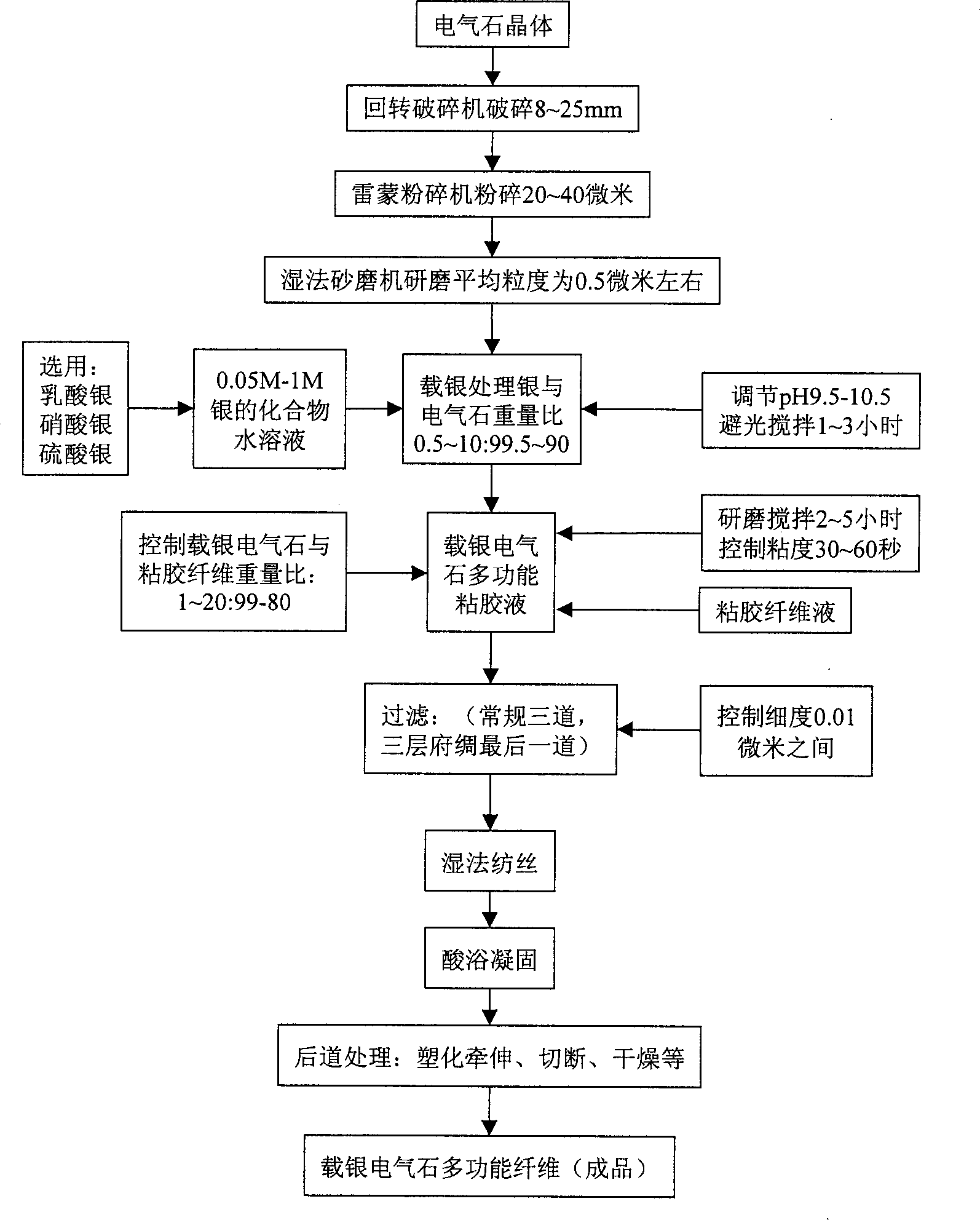

Method used

Image

Examples

Embodiment 1

[0035] 10 kilograms of black tourmaline are broken into blocks with an outer diameter of 15 mm by a rotary crusher; then pulverized into a coarse powder with a particle size of 30 microns by a Raymond mill; Join in the sand mill, grind and pulverize 10 hours, measure with the centrifugal sedimentation method particle size analyzer that Shimadzu Corporation produces, and average particle size is 0.5 micron; 0.75 kilogram of silver nitrate is dissolved in 5 kilograms of deionized water, join in In the sand mill, pulverize and grind for 2 hours to finally obtain 40 liters of slurry, in which the silver-loaded tourmaline content is 280 g / liter; adjust the pH to 10; evenly add the silver-loaded tourmaline slurry to the viscose to control the silver-loaded tourmaline The weight ratio with the viscose fiber is 6:94, after 2-5 hours of thorough mixing and grinding, the viscose with silver-loaded tourmaline function is made into a viscosity of 50 seconds; the silver-loaded tourmaline fu...

Embodiment 2

[0037]10 kilograms of black tourmaline are broken into blocks with an outer diameter of 8 mm by a rotary crusher; then pulverized into a coarse powder with a particle size of 20 microns by a Raymond mill; Add in the sand mill, grind and pulverize for 10 hours, measure with the centrifugal sedimentation method particle size analyzer that Shimadzu Corporation produces, and the average particle diameter is 0.48 microns; In the sand mill, crush and grind for 2 hours to finally obtain 40 liters of slurry, in which the silver-loaded tourmaline content is 280 g / liter; adjust the pH to 9.5; evenly add the silver-loaded tourmaline slurry to the viscose to control the silver-loaded tourmaline The weight ratio with the viscose fiber is 20:80, and after 2-5 hours of thorough mixing and grinding, a functional viscose with a silver-loaded tourmaline with a viscosity of 30 seconds is made; the silver-loaded tourmaline functional viscose is Add 1-3 layers of poplin filter cloth to filter afte...

Embodiment 3

[0039] 10 kilograms of black tourmaline are crushed into blocks with an outer diameter of 25mm through a rotary crusher; then pulverized into a coarse powder with a particle size of 40 microns through a Raymond mill; Join in the sand mill, grind and pulverize 10 hours, measure with the centrifugal sedimentation method particle size analyzer that Shimadzu Corporation produces, and average particle size is 0.52 micron; 0.75 kilogram of silver sulfates are dissolved in 5 kilograms of deionized water, join in In the sand mill, crush and grind for 2 hours to finally obtain 40 liters of slurry, in which the silver-loaded tourmaline content is 280 g / liter; adjust the pH to 10.5; evenly add the silver-loaded tourmaline slurry to the viscose to control the silver-loaded tourmaline The weight ratio with the viscose fiber is 1:99, after 2-5 hours of thorough mixing and grinding, the viscose with silver-loaded tourmaline function is made into a viscosity of 60 seconds; the silver-loaded to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com