Flapping-wing flying water automobile

A flying car and wing technology, applied in the field of transportation, can solve the problems of large flight resistance, low flight speed, insufficient power, etc., and achieve the effects of small radar reflection area, high flight efficiency, and low air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

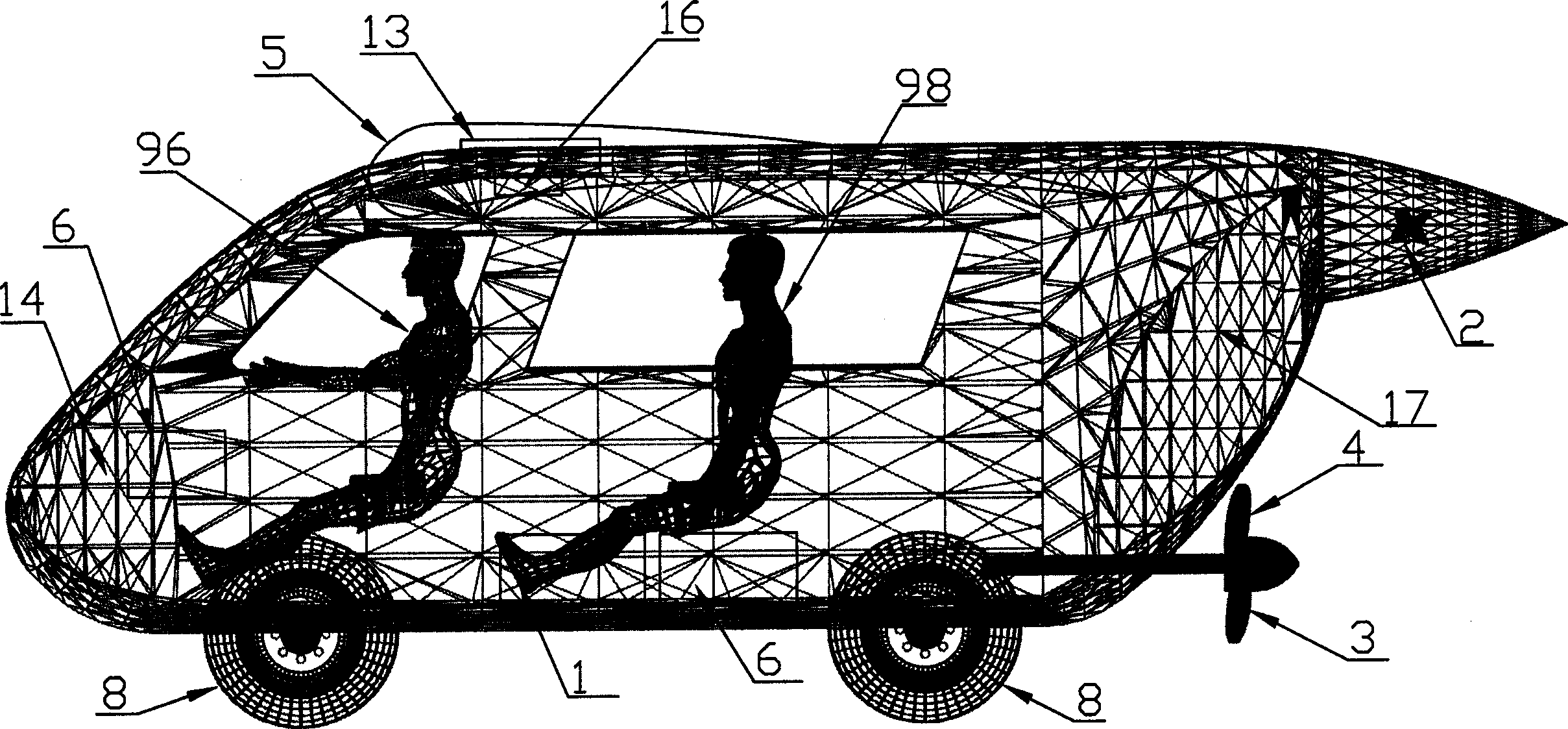

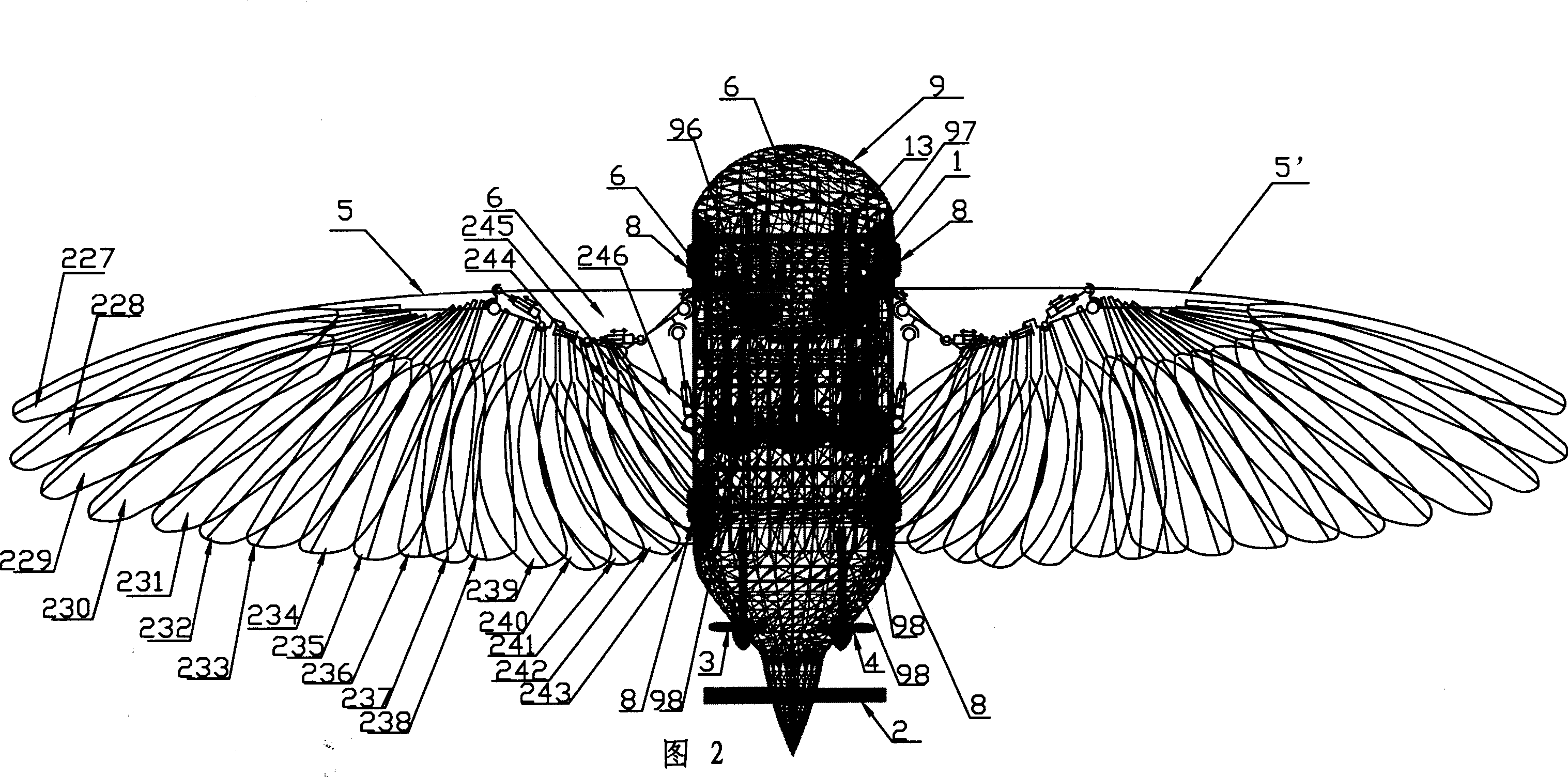

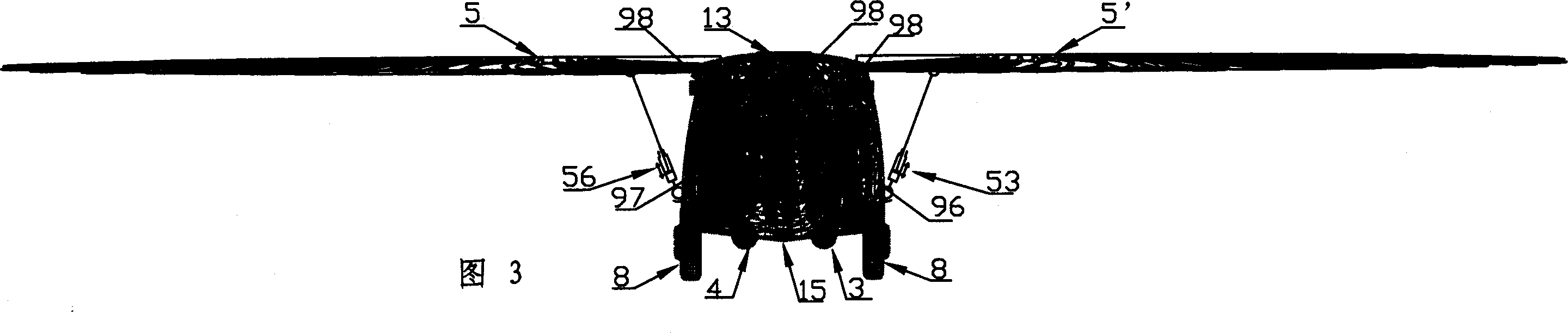

[0047] The structure diagram of the present invention is as figure 1 , shown in Fig. 2, Fig. 3, comprise engine (1), air two-blade variable-pitch propeller (2), left and right hydrodynamic propeller (3,4), left and right wing (5,5 '), Control system (6), safety and life-saving equipment (7), four-wheel landing gear and suspension shock absorber (8), fuselage (9), including engine (1), control system (6), safety and life-saving equipment ( 7) are all placed in the fuselage (9), the air double-blade variable-pitch propeller (2) is fixed on the tail of the fuselage (9), and the left hydrodynamic propeller (3) and the right hydrodynamic propeller (4) are respectively installed On both sides of the fuselage (9), the wings (5) are installed on the top of the fuselage (9), and the four-wheel landing gear and the suspension shock absorber (8) are installed on both sides of the bottom of the fuselage (9). , wherein the wing (5) is connected with the fuselage (9) through the machine-hy...

Embodiment 2

[0080] The structure embodiment 1 of the present invention is identical, and difference is that above-mentioned left and right wing (5,5 ') also can be inflatable foldable wing, and the structure that it is connected with machine-fluid combination mechanism and vane combined type can Folding wing is identical, and the inflatable foldable wing comprises some air chambers that are made up of A group air chamber and B group air chamber, and some air chambers are respectively connected with each air chamber by upper and lower two layers of elastic covering cloth (26,27). As shown in Figure 16, the air chamber separator on the wing front side has only ribs (23), and all the other air chamber separators include rib beams (24) and ribs (23), and the ribs Beam (24) is thin cone, and its diameter is the largest at the root, and the tail end is the smallest, such as Figure 14-1 As shown, the connecting rod (221) is connected with the rib beam (24) of the wing A group air chamber, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com