Technology for making strengthened glass circuit board and its product and application

A technology for strengthening glass and circuit boards, which is applied in printed circuit manufacturing, circuit substrate materials, printed circuits, etc., and can solve problems such as short service life, high cost, and poor electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

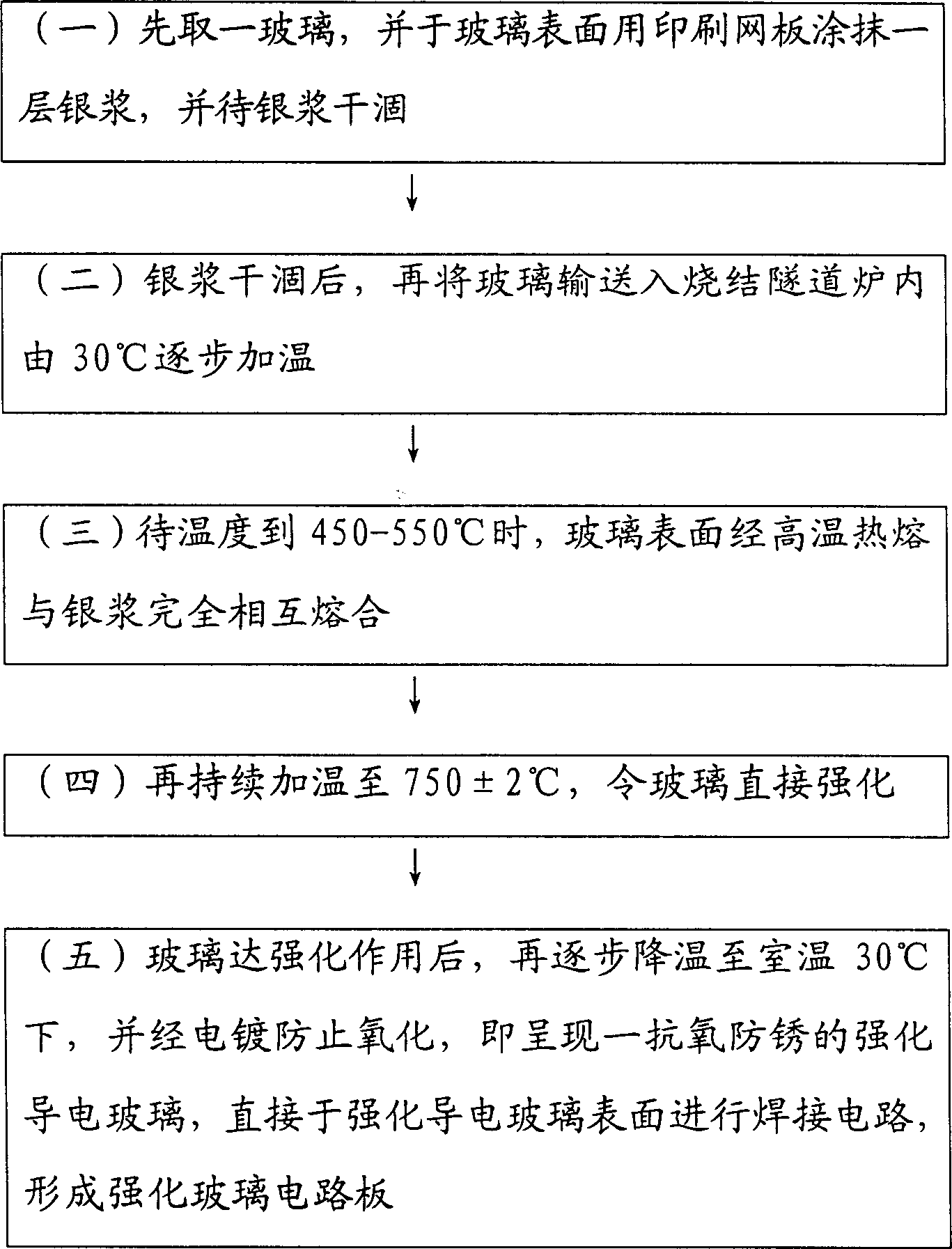

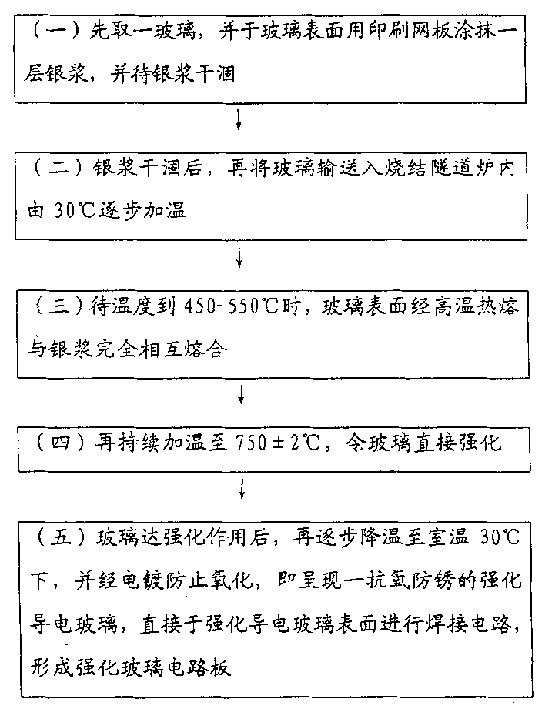

[0023] refer to figure 1 Shown, preparation method of the present invention comprises the following steps:

[0024] A. Take a piece of glass first, and smear a layer of silver paste on the surface of the glass with a printing screen. The composition and composition of the silver paste are 68-72 parts by weight of silver powder, 78-82 parts of coagulant, and 1-3 parts of glass powder. Parts, 3-5 parts of resin and 14-19 parts of organic solvent, the viscosity is 400±50p (poise), and placed at 150 ° C for ten minutes, until the silver paste is dry, due to the coagulant, resin and organic solvent It is a general raw material well known to those skilled in the art, so it will not be described in detail;

[0025] B. After the silver paste dries up, the glass is transported into the sintering tunnel furnace and gradually heated at 30°C;

[0026] C. When the temperature reaches 450-550°C, the glass surface is melted at high temperature, and at the same time, it is completely fused ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com