Manufacturing process of Christmas tree decorations and racks for their fixing during this process

A manufacturing method and a decoration technology, applied in the manufacture of Christmas tree decorations, and the field of shelves for fixing Christmas tree decorations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

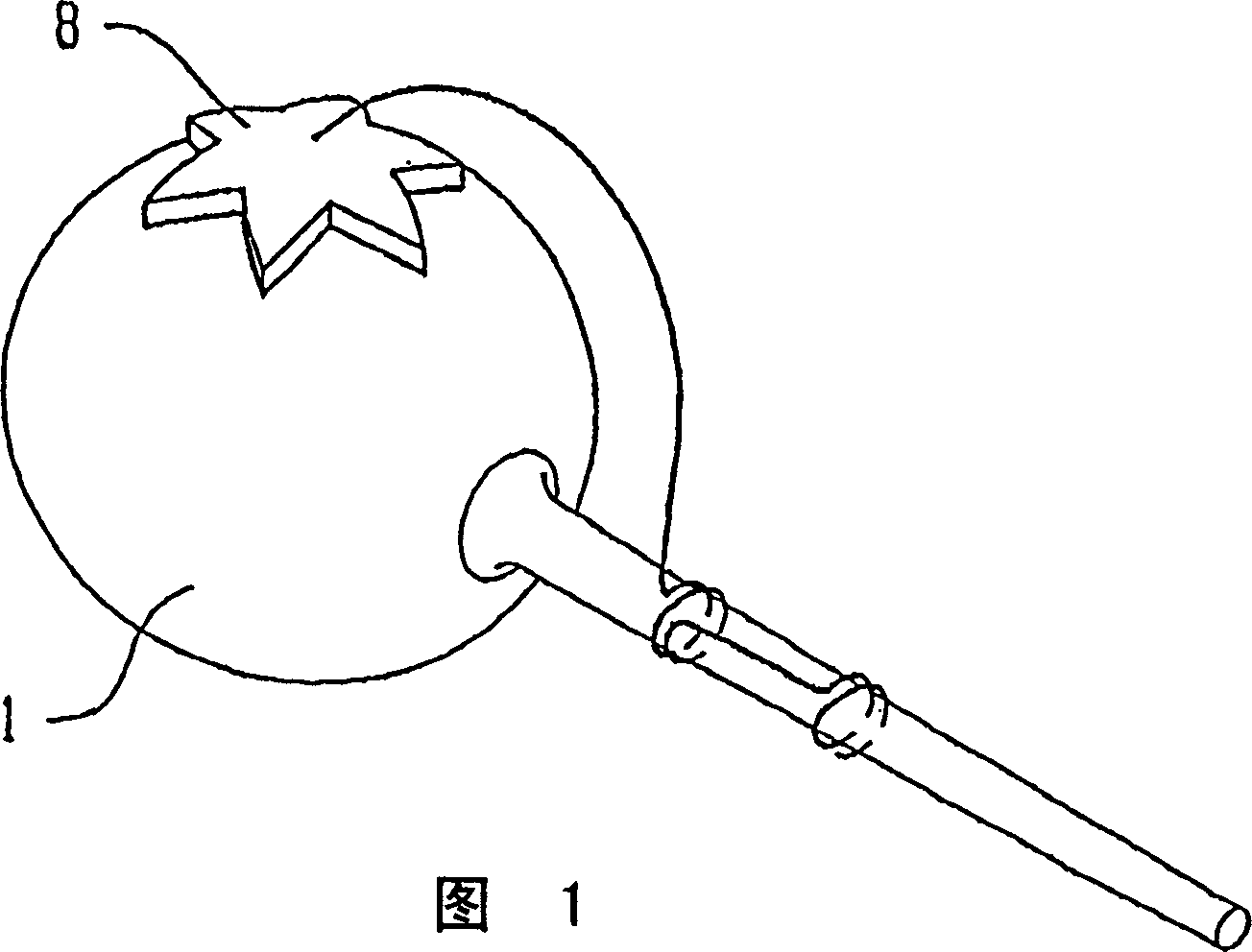

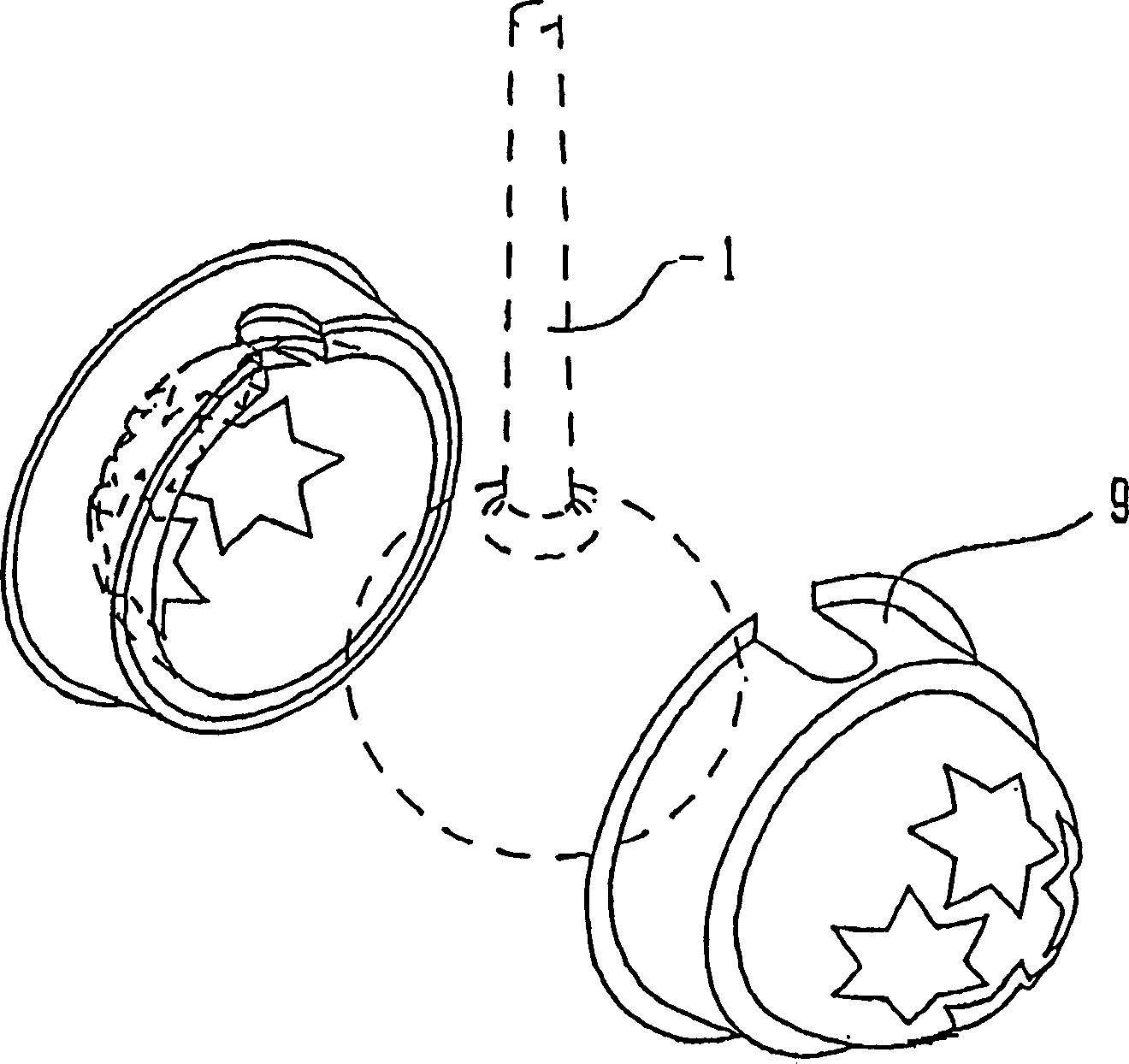

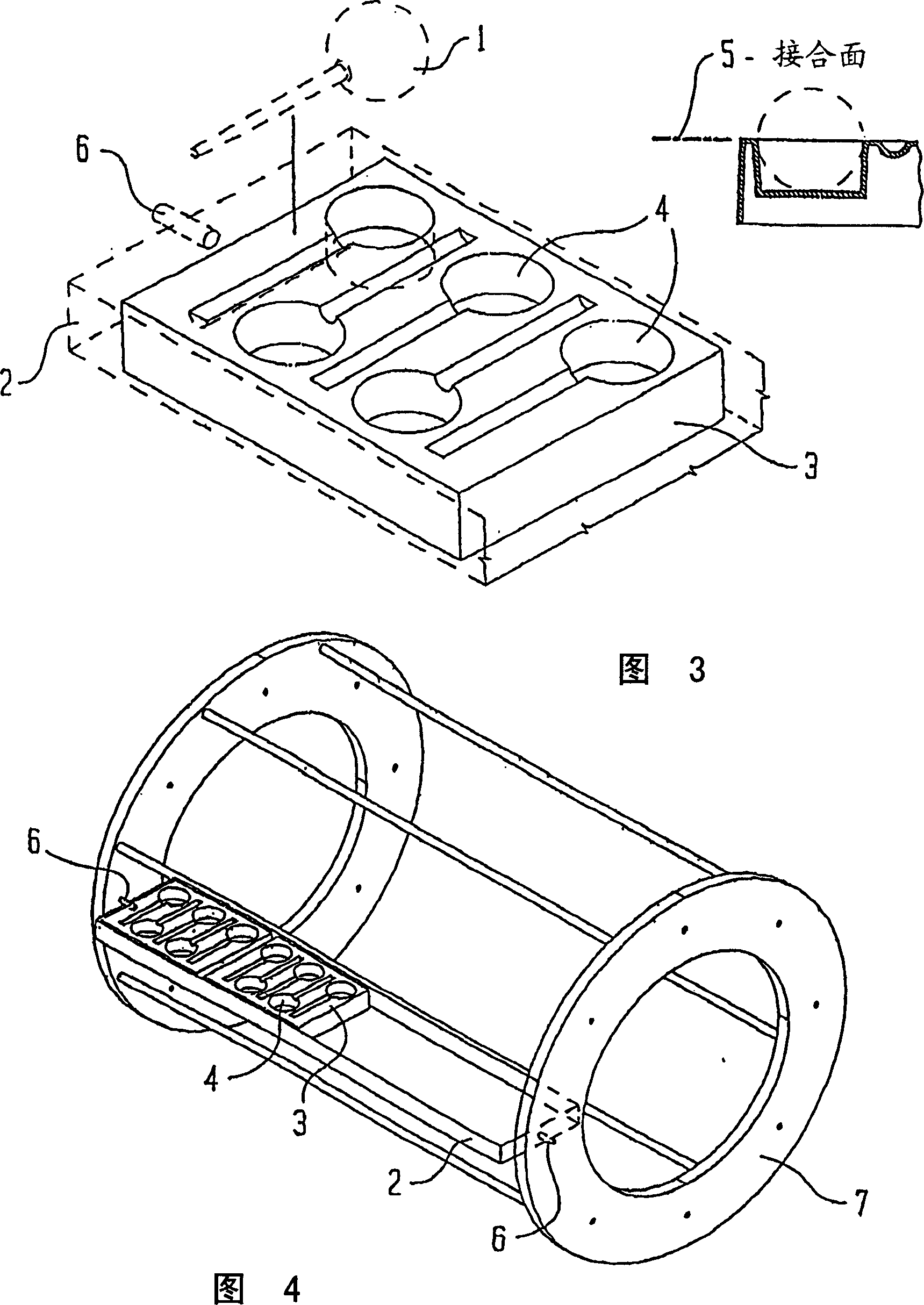

[0017] In the production method of the Christmas tree ornament according to the proposed invention, the glass semi-finished product 1 is first blown to the required size and shape using conventional methods; this semi-finished product is fixed with a handle at its end. The glass semifinished product 1 obtained in this way is then fixed in a shelf suitable for the type of semifinished product described below. The rack containing the glass semi-finished products is then put into a metal painting unit. In this device, a thin layer of metals and / or their alloys (1 to 7 microns thick) is formed on the treated surface using vacuum coating or powder coating methods. The thickness of the coating is subject to ensuring opacity. The following metals or their alloys can be used for this operation: aluminum, copper, iron, nickel, silver, gold, magnesium, tin, chromium, vanadium and zinc. After the painting is completed, the semi-finished glass 1 pass Painted with clear or colored glos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com