Yarn twisting device

A technology of yarn and braking device, which is applied in piecing device, spinning machine, loading/unloading, etc., can solve problems that cannot be eliminated, avoid downtime, improve yarn quality and winding positioning, and reduce trial and error The effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

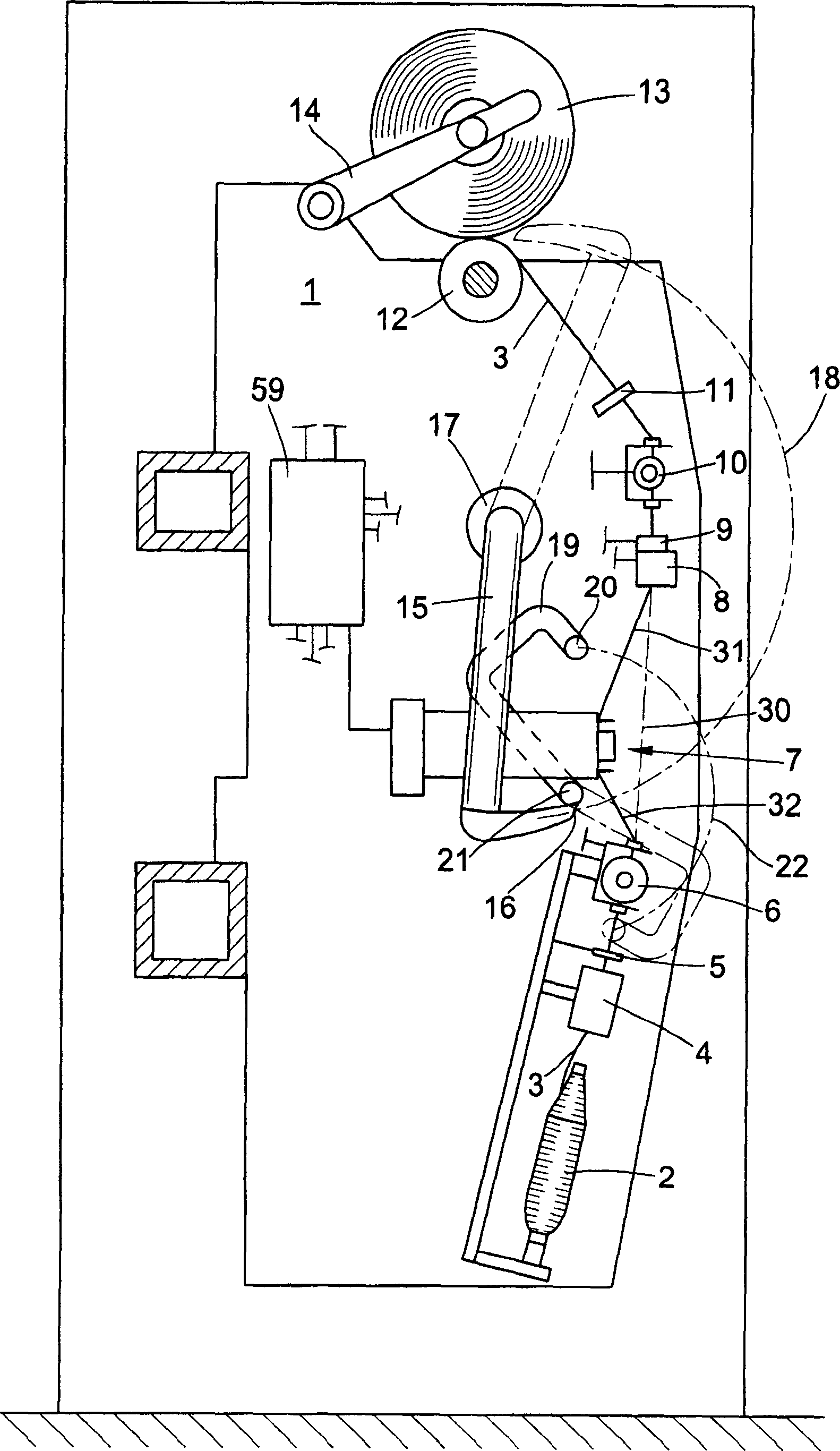

[0025] figure 1 The winding position 1 shown is part of a textile machine for the production of cross-wound bobbins. This kind of textile machine is also called a winding machine, and there are many winding spindles arranged in parallel. The structure and function of this winding spindle are known, so the following is only a brief description of the winding machine.

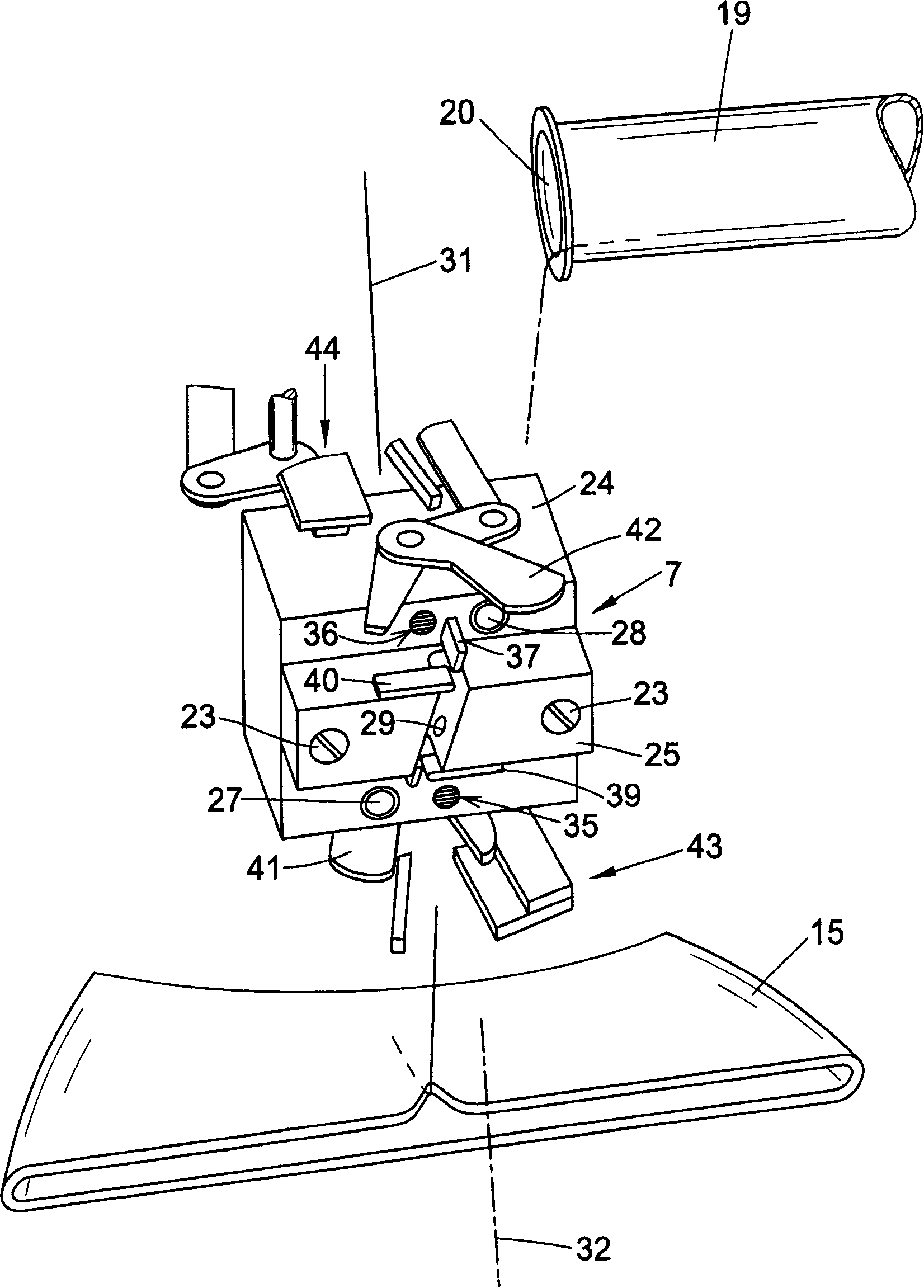

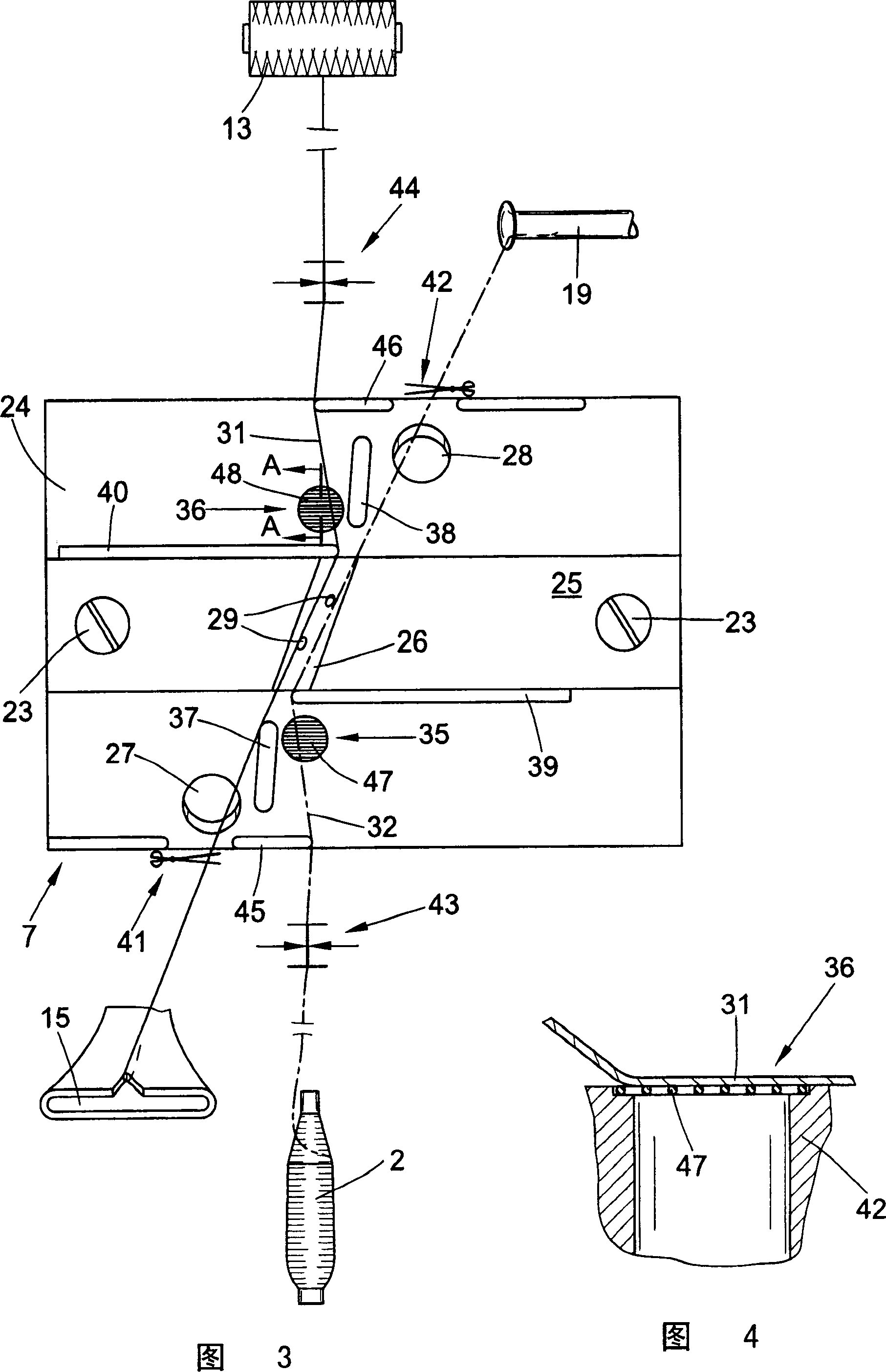

[0026] The yarn 3 is unwound from the bobbin 2 and passed through the balloon breaker 4 and the thread guide eye 5 to a yarn tensioner 6 . A yarn splicing device is arranged between the yarn tensioner 6 and the yarn clearer 8 . During the winding process, the yarn 3 occupies a yarn path marked with the reference numeral 30 . The yarn cutter 9 arranged beside the yarn clearer 8 is used to cut the yarn 3 when the yarn clearer 8 determines that the set quality value of the yarn 3 exceeds the range. After the yarn 3 passes through the yarn cutter 9, it passes through a waxing device 10, and then enters a groove d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com