Prepn. process and apparatus of polytetramethylene ether glycol

The technology of a polytetramethylene ether glycol and a monitoring device is applied in the field of preparing polytetramethylene ether glycol, and can solve the problems of uneconomical, large space of the settling tank and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

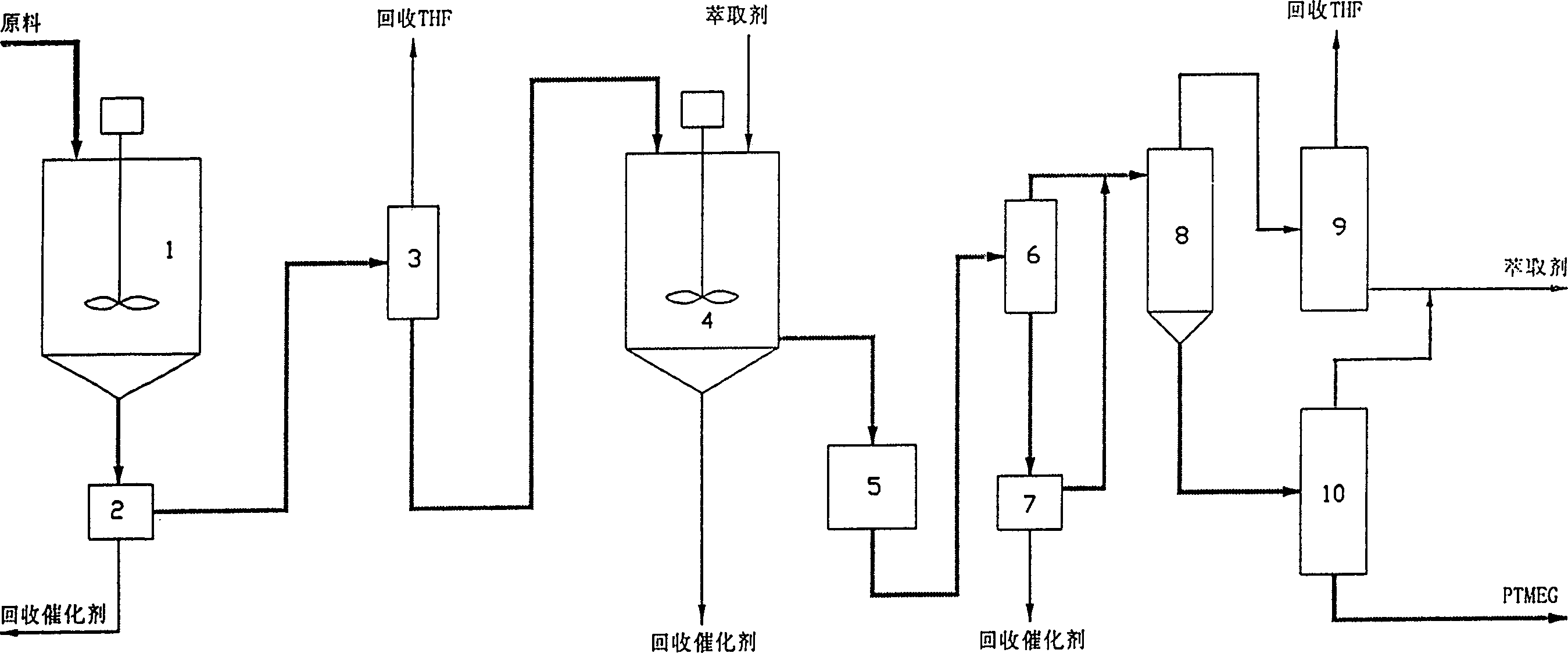

[0089] Embodiment 1: prepare PTMEG technology and the control of PTMEG molecular weight in reactor

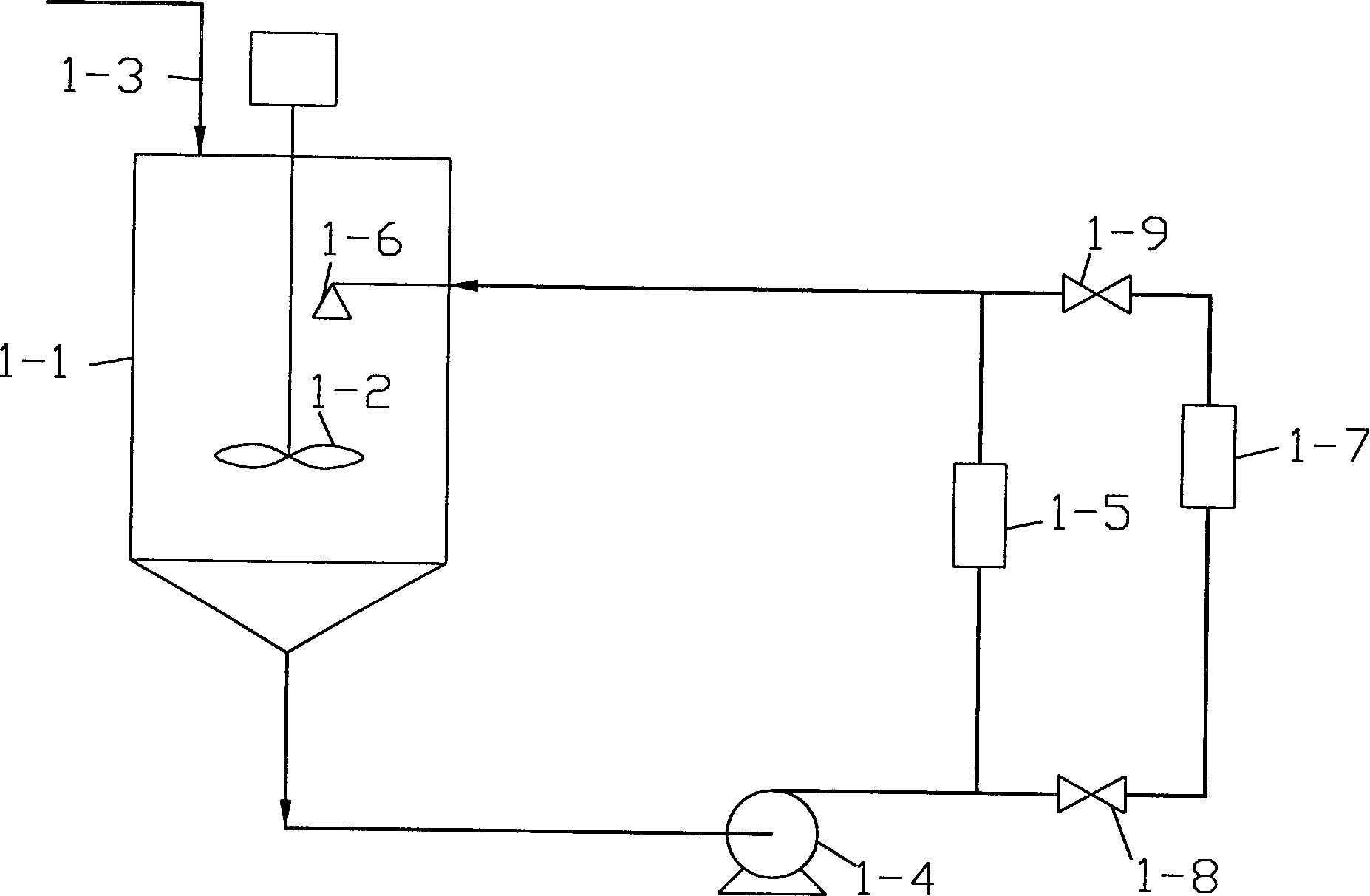

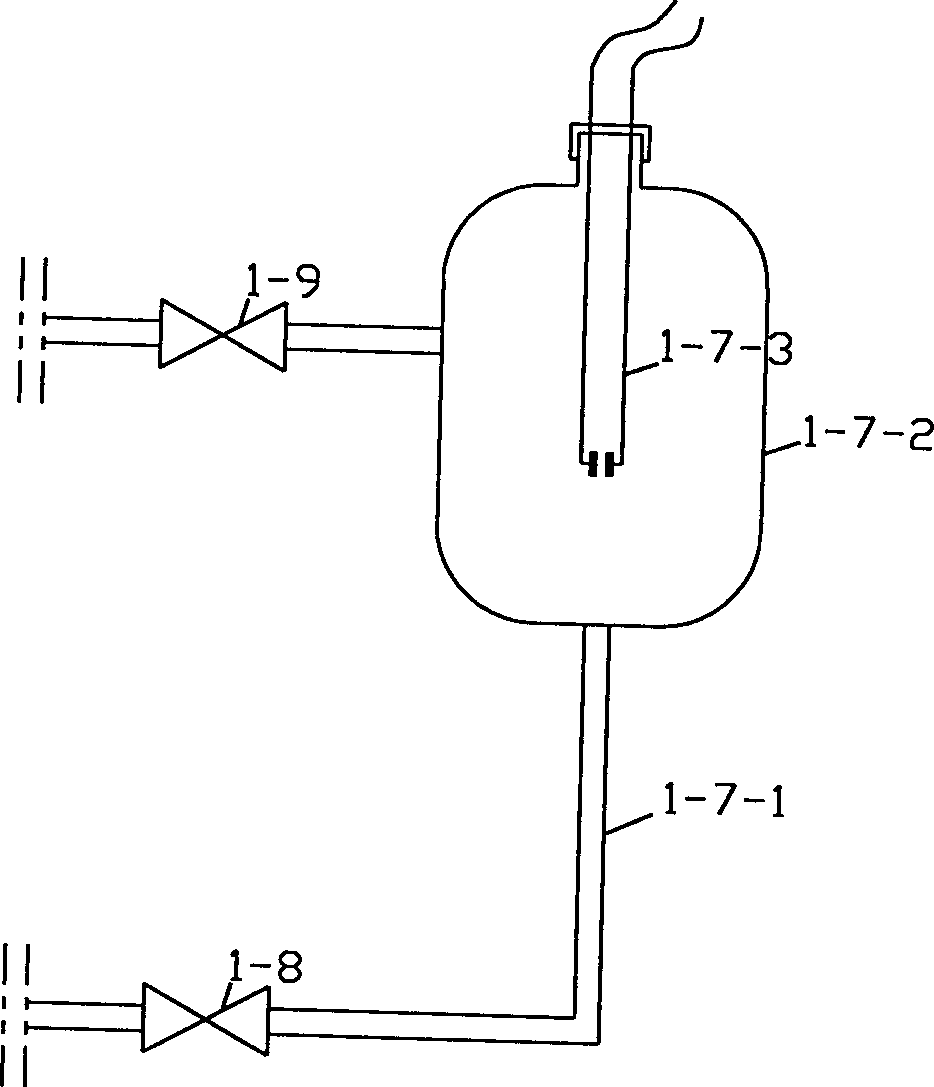

[0090] Towards figure 1 and figure 2 Add 200Kg THF in the shown reactor 1 with external circulation, 100Kg contains 12 tungstophosphoric acid catalysts of 3-5 crystal waters, after opening the agitator 1-2, start to slowly add process water (0.2kg / min), while Open the external circulation system and open the valves 1-8 and 1-9, the molecular weight monitoring device participates in the circulation, after 2.5 minutes, stop adding water, close the valves 1-8, 1-9. After 1 minute, the reaction material is in the expansion body 7-2 Automatic stratification in the middle, the lower part is the catalyst phase, and the upper part is the organic phase containing dissolved catalyst and unreacted tetrahydrofuran. The conductivity meter is inserted into the organic phase to measure the conductivity at the initial stage. If the conductivity is less than 8ms / cm (corresponding to the con...

Embodiment 2

[0091] Embodiment 2. extractor and extraction process thereof

[0092] To a traditional extractor (without a central draft tube and a lower settling zone, e.g. Handbook of Chemical Engineering, Part 5, Stirring and Mixing, Figure 4-3 on page 56, Liquid-liquid phase agitator for extraction, Chemical Industry Publishing House, December, 1985, the first edition of Beijing), and the extractor 4 of the present invention respectively add 30 liters of feed liquid at the bottom of the first flasher 3, the feed liquid consists of about 85wt% of PTMEG, 15wt% of tetrahydrofuran and a trace amount of The impurity such as the catalyst of dissolving, add 60kg toluene extractant respectively to two extractors, traditional extractor temperature control 65 ℃, extractor temperature control 60 ℃ of the present invention. After the traditional extractor was stirred for 1.5 hours, the precipitated catalyst phase was discharged in a controlled manner from the bottom of the extractor, and the stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com