High-strength porous casing and pipeline parts of nano polyvinyl chloride and their production process

A polyvinyl chloride and polyvinyl chloride resin technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of fragility, affecting the quality of buried pipes, low strength and toughness, etc., and achieve mechanical properties Good, light weight, convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Production casing:

[0029] (1) Ingredients: (by weight) nano polyvinyl chloride resin: 100, heat stabilizer: 3, lubricant: 2, impact modifier: 8, processing modifier: 2, flame retardant: 4 mixed preparation;

[0030] (2) Stirring: Stir the prepared raw materials in a high-speed mixer until the temperature reaches 105°C, then stir in a low-speed cold mixer to cool down to 60°C, and put them into the storage bin for standby;

[0031] (3) Extrusion: Use 65 or 55 twin-screw extruder to extrude the stirred material into the billet;

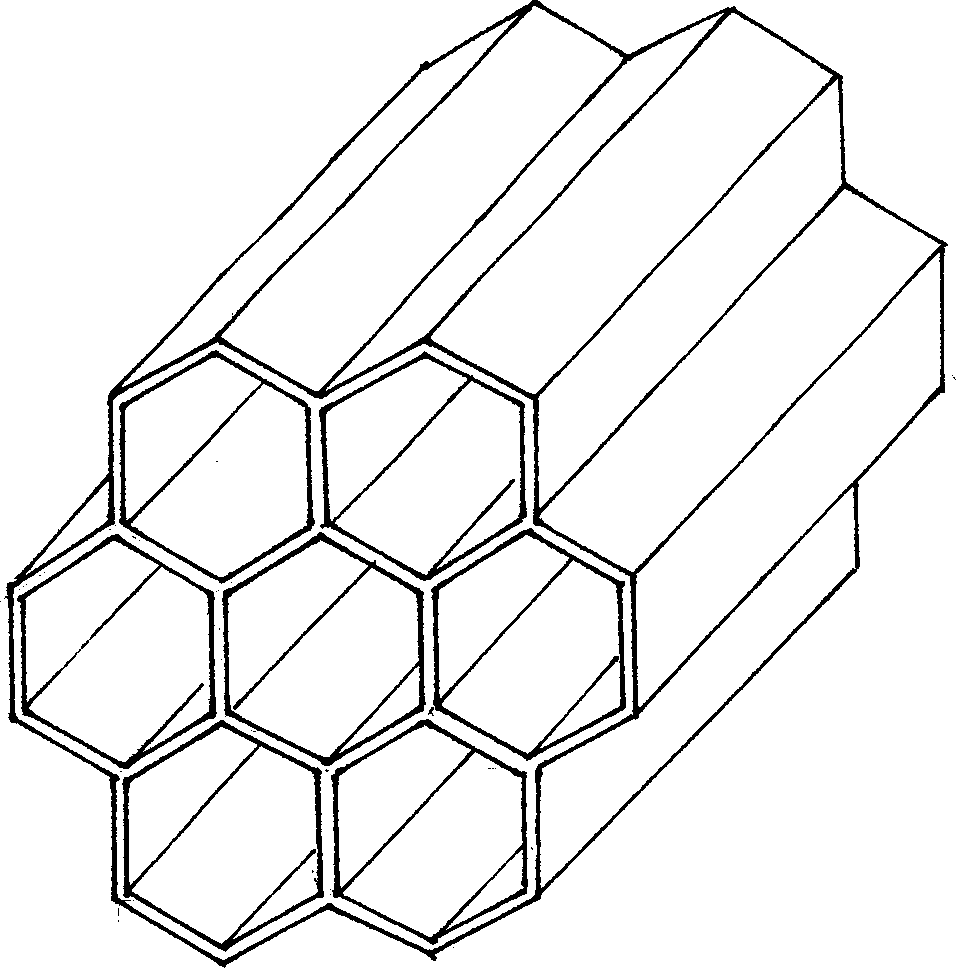

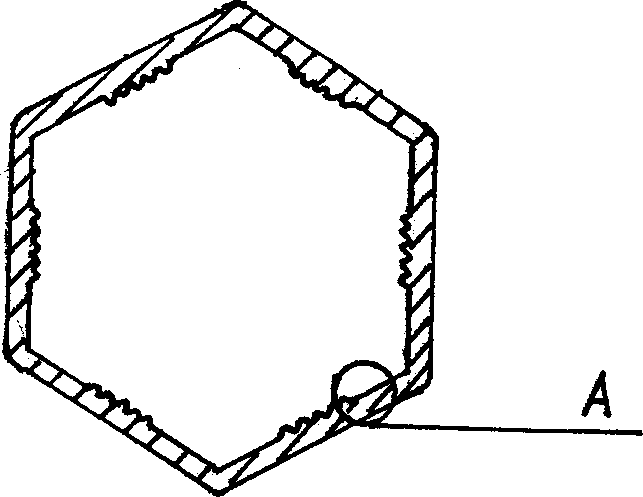

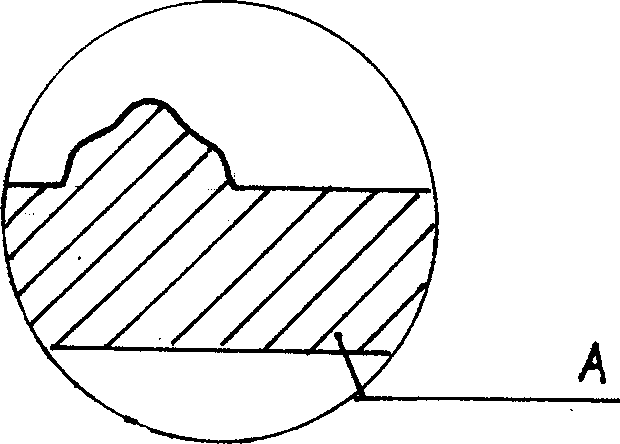

[0032] (4) Vacuum shaping: formed into a porous casing, such as figure 1 As shown, the casing structure is a bioengineering honeycomb arrangement with the closest packing of regular hexagonal lumens, such as figure 2 , image 3 As shown, the inner surface of the casing cavity is provided with imitation bioengineering spine-convex ribs;

[0033] (5) Cut to length;

[0034] (6) Inspection, packaging, storage.

[0035] (2) Production o...

Embodiment 2

[0044] (1) Process steps for producing casing:

[0045] (1) Ingredients: (by weight) nano polyvinyl chloride resin: 100, heat stabilizer: 3.5, lubricant: 3, impact modifier: 10, processing modifier: 2.5, flame retardant: 3 mixed preparation;

[0046] (2) Stirring: Stir the prepared raw materials in a high-speed mixer until the temperature reaches 100°C, then stir in a cooling mixer to cool down to 60°C, and put them into the storage bin for standby;

[0047] (3) Extrusion: Use 65 or 55 twin-screw extruder to extrude the stirred material into the billet;

[0048] (4) Vacuum shaping: formed into a porous casing, such as figure 1 As shown, the casing structure is a bioengineering honeycomb arrangement with the closest packing of regular hexagonal lumens, such as figure 2 , image 3 As shown, the inner surface of the casing cavity is provided with imitation bioengineering spine-convex ribs;

[0049] (5) Cut to length;

[0050] (6) Inspection, packaging, storage.

[0051] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com