Photoetching method for nanoparticle pattern based on self organization

A nano-lithography and nano-particle technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as lack of versatility, and achieve good compatibility and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

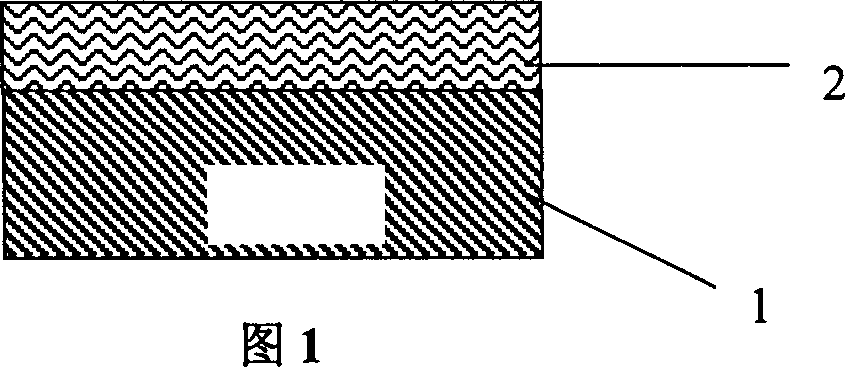

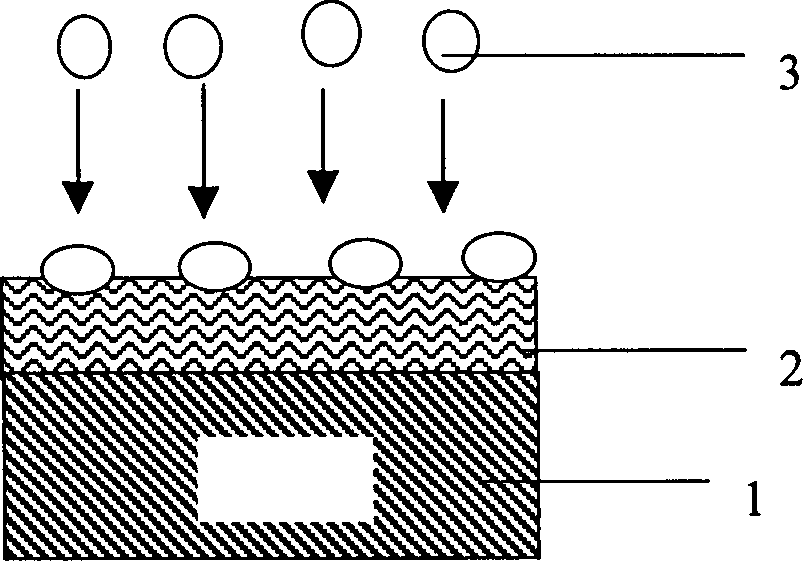

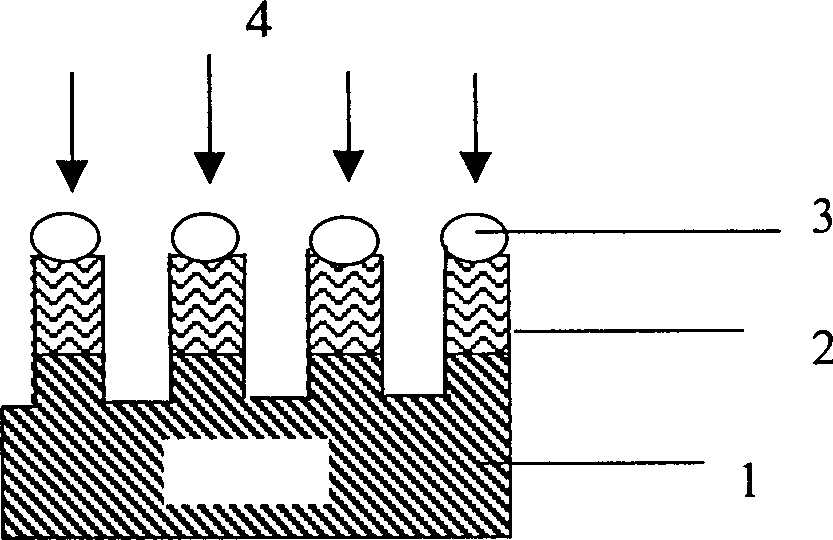

[0017] Taking the Si substrate material as an example (the basic process flow of other substrates such as Ge, GaAs, SOI, etc. is the same), the method is further described in detail. Its production process is as shown in Figure 1- Figure 4 Shown:

[0018] 1. Preparation of submicron periodic templates (Figure 1):

[0019] (1) Select an appropriate organic substance, such as polystyrene-polybutadiene or polydimethylsiloxane, as a template material.

[0020] (2) Form a periodic and ordered spatial self-organization structure on the surface of the substrate through the self-assembly of organic substance molecules or driven by the outside world (such as noise regulation). From the perspective of process compatibility, mainly through organic vapor deposition, high-speed spin coating (spincoating) and high-vacuum anion polymerization technology, combined with substrate induction, noise control and other methods, the formation of template materials such as block copolymers on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com