Method for producing isobutene and methanol

A technology of isobutylene and methanol, applied in the directions of organic chemistry methods, chemical instruments and methods, hydrolysis preparation, etc., can solve the problems such as reduced catalytic activity of methyl-tert-butyl ether decomposition, economic efficiency defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

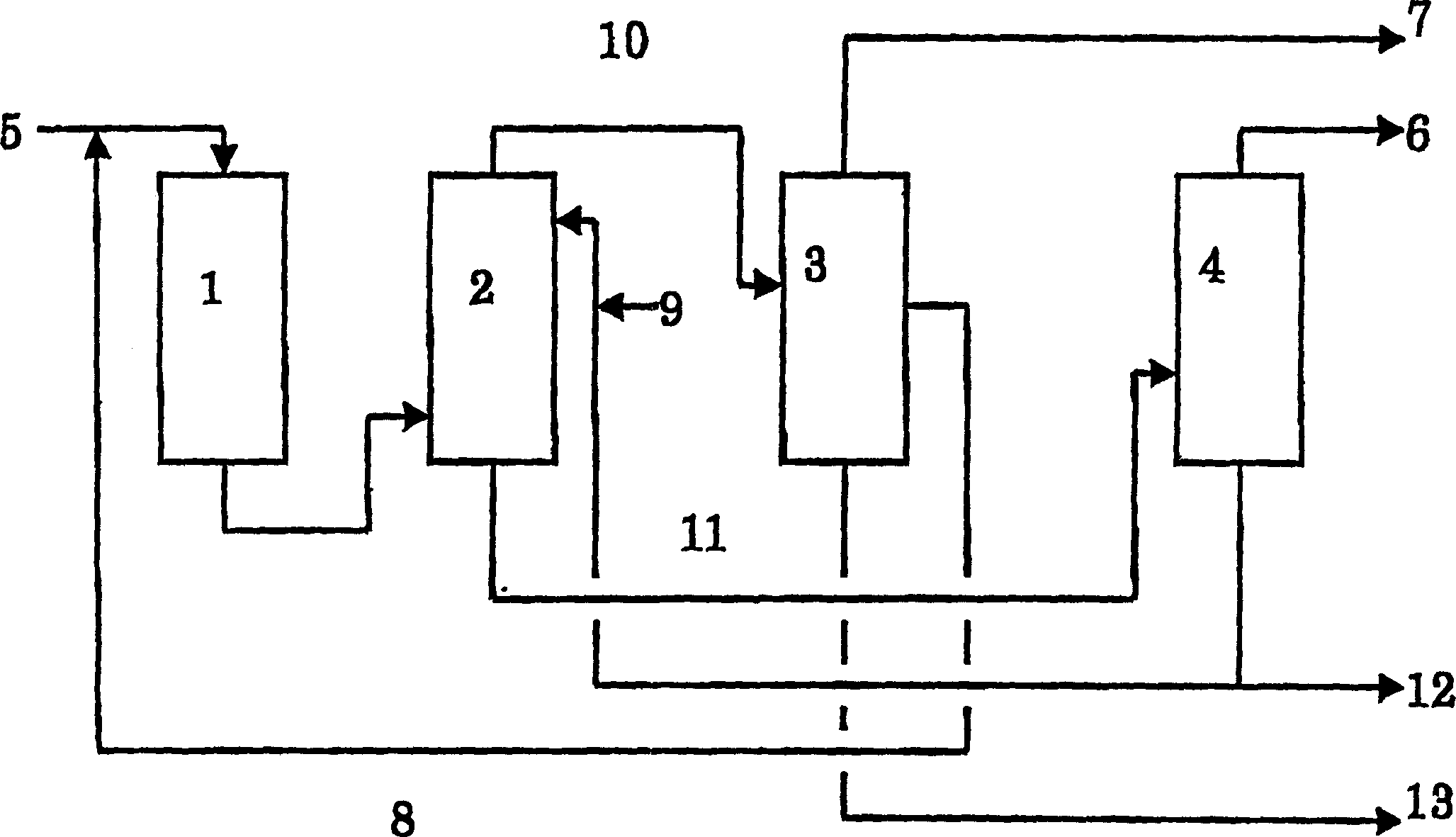

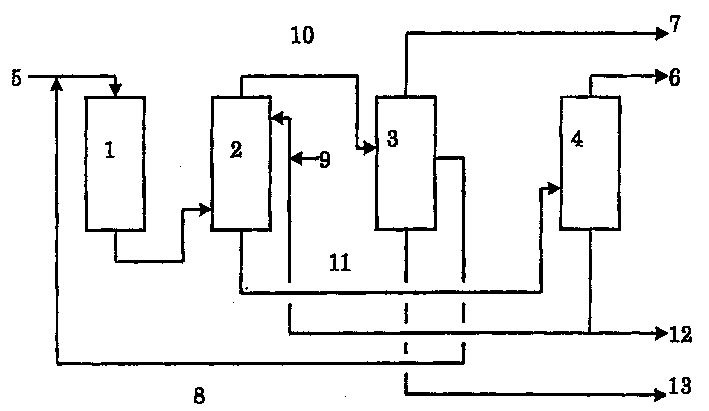

[0043] Embodiment 1 and comparative example 1 such as figure 1 As shown in the flow chart of , Example 1 uses the following first step to fourth step. The abbreviations in the table are as follows: MTBE: methyl-tert-butyl ether; DIB: isobutylene dimer; DME: dialkyl ether; and TBA: tert-butanol.

[0044] The first step: in the presence of a solid acid catalyst containing alumina, the decomposition reaction of methyl-tert-butyl ether is carried out to obtain isobutylene, methanol and dialkyl ether and by-product heavy components, wherein the heavy components include isobutylene di polymers and isobutylene terpolymers. A fixed bed gas phase reaction is used. The reaction temperature is 220°C, and the reaction pressure is 6kg / cm 2 g. The feed rate of methyl-tert-butyl ether is LHSV 3(h -1 ) The reaction gas becomes liquid after being cooled by heat recovery equipment.

[0045] The second step: washing the reaction liquid obtained in the first step with water, and separating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com