Method and apparatus for obtaining liquid nitrogen by utilizing liquefied natural gas cold energy

A technology of liquefied natural gas and natural gas, applied in the low temperature field, can solve the problem of consuming large electric energy and achieve the effect of large economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

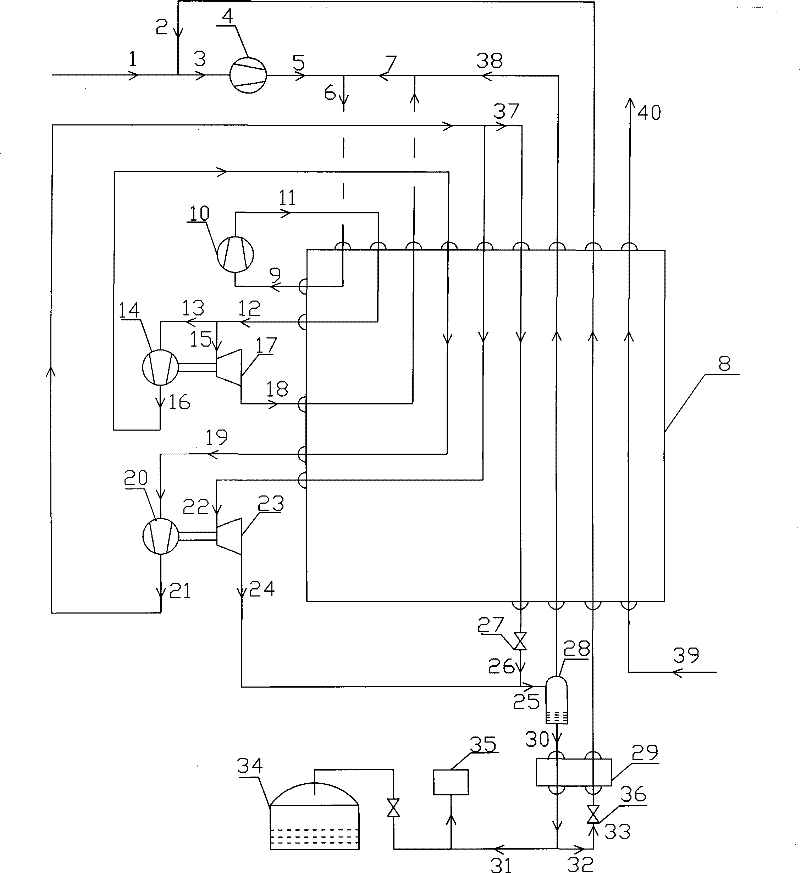

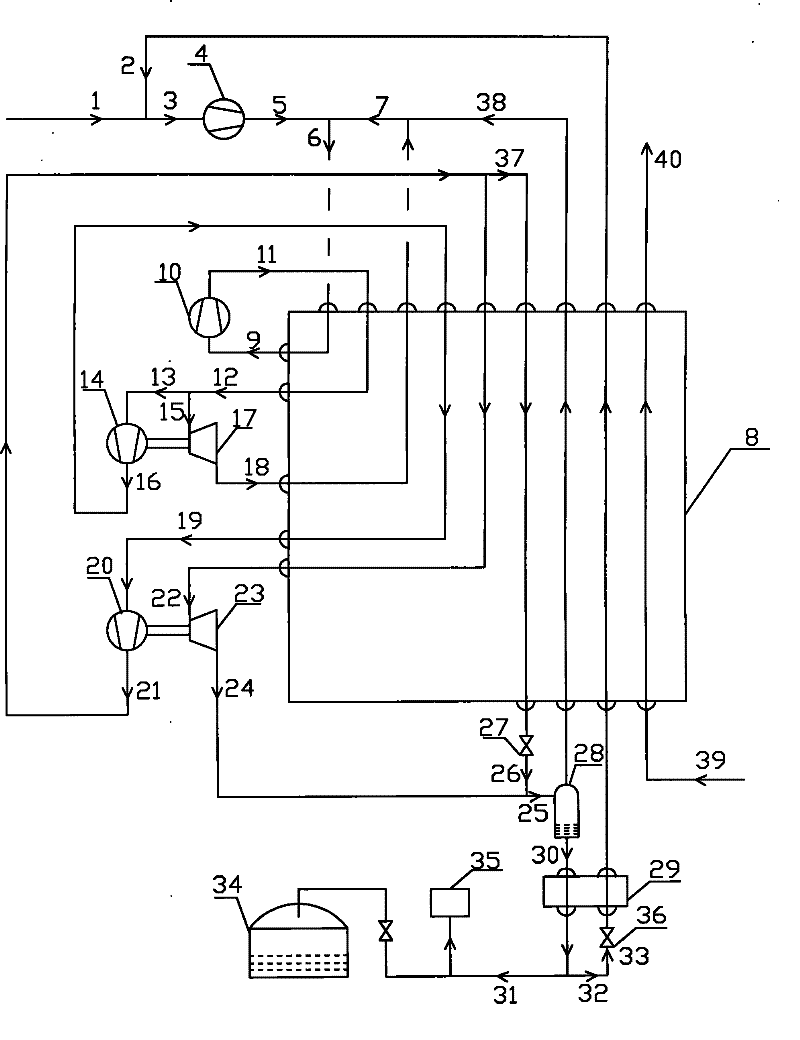

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The device for obtaining liquid nitrogen by using the cold capacity of liquefied natural gas according to the present invention at least includes a low-temperature nitrogen cycle machine, a nitrogen gas turbine compressor, a natural gas heat exchanger, a high-temperature supercharged turbo expander, a low-temperature supercharged turbine A liquefied natural gas cold recovery device composed of a flat expander, a vapor-liquid separator and a liquid nitrogen subcooler. In the natural gas heat exchanger, there is at least one natural gas heat exchange flow channel, and at least four nitrogen heat exchange flow channels are arranged on the natural gas heat exchanger, wherein the first and second heat exchange flow channels are provided with A low-temperature nitrogen cycle machine, a high-temperature booster turbo expander is installed between the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com