Filtering material for removing smoke of cigarette and its preparing method

A smoke and cigarette technology, which is applied in the field of microporous sponge filter elements, achieves the effects of low energy consumption, good adsorption and purification functions, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

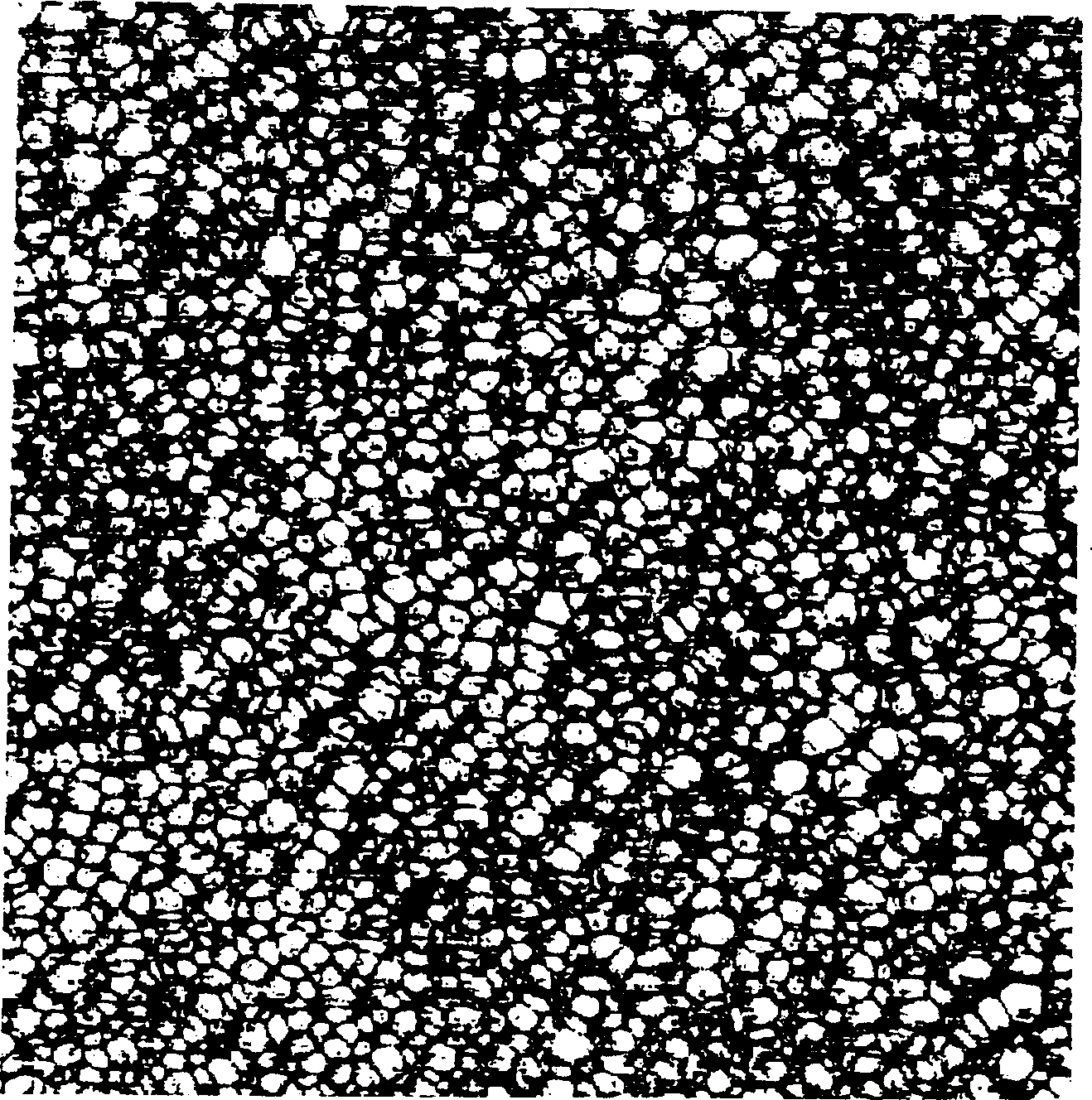

Image

Examples

Embodiment 1

[0018] In the present invention, cheap natural black tourmaline, zeolite, far-infrared zirconia and titanium dioxide powders are mixed to prepare a mineral microcrystalline composite material, wherein the black tourmaline is produced in the middle of the Maguan-Malipo ore belt in Yunnan, and the main mineral composition and The chemical composition is shown in Table 1 and Table 2. Zeolite, far-infrared zirconia and titanium dioxide powders were purchased from the market, and the main components were Na[AlSi 5 O 12 ]3H 2 O, ZrO 2 and TiO 2 .

[0019] First, the natural minerals black tourmaline and zeolite are respectively rinsed, dried, and pulverized; then, they are mixed according to the following weight percentages: tourmaline microcrystal: zeolite: far-infrared zirconia powder: titanium dioxide powder=60%: 12%: 10%: 18%; ball-milled until the particle size of the powder is about 120 mesh, and then the above-mentioned microcrystalline composite powder is slowly heated ...

Embodiment 2

[0024] The present invention selects and mixes cheap natural black tourmaline, zeolite, infrared zirconia and titanium dioxide powder to prepare a mineral microcrystalline composite material. The chemical compositions are shown in Tables 3 and 4. Zeolite, far-infrared zirconia and titanium dioxide powders were purchased from the market, and the main components were Na[AlSi 5 O 12 ]3H 2 O, ZrO 2 and TiO 2 . First, the natural minerals black tourmaline and zeolite were rinsed, dried and pulverized respectively; then mixed according to the following weight percentages: tourmaline crystallites: zeolite powder: far-infrared zirconia powder: titanium dioxide powder = 65%: 10%: 10 %: 15%; then ball-milled to a particle size of about 100 mesh.

[0025] Then, the above-mentioned microcrystalline composite powder is slowly heated to 450° C. in a box-type heating furnace, kept for 4 hours, and then cooled to room temperature with the furnace to complete the activation treatment of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com