Method for preparing oil-displacing agent of high-tack-producing hydrophobic association polymer

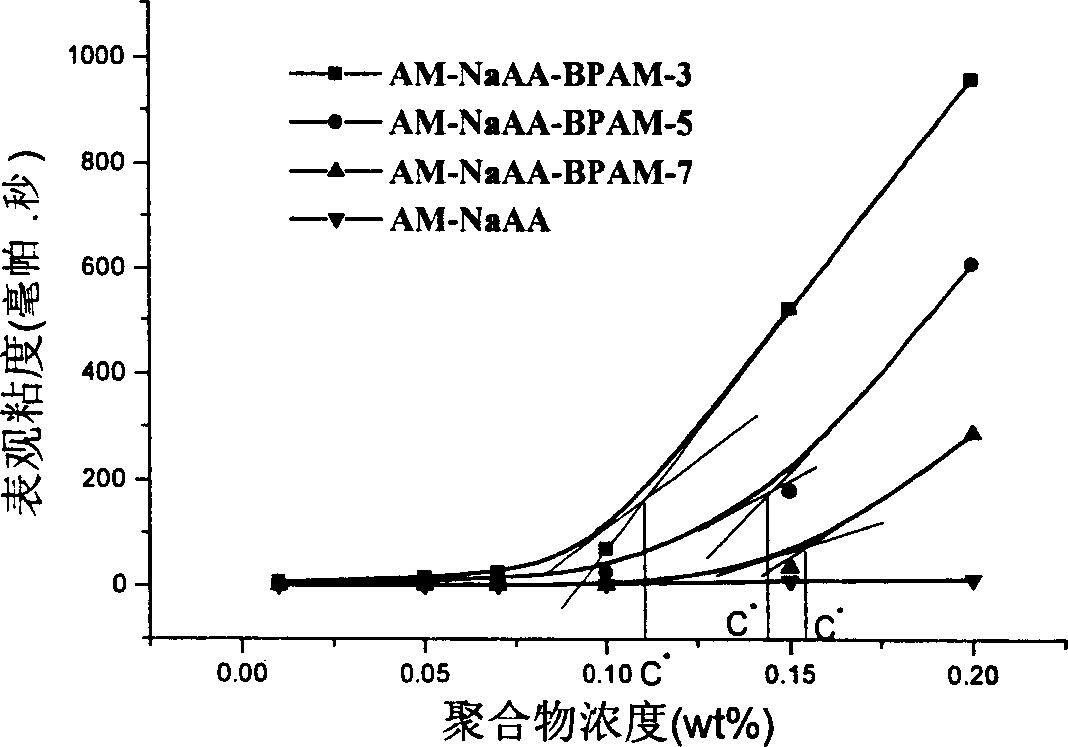

A technology of hydrophobic association and water-soluble polymers, which is applied to drilling equipment and other fields, and can solve the problems of high critical association concentration and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

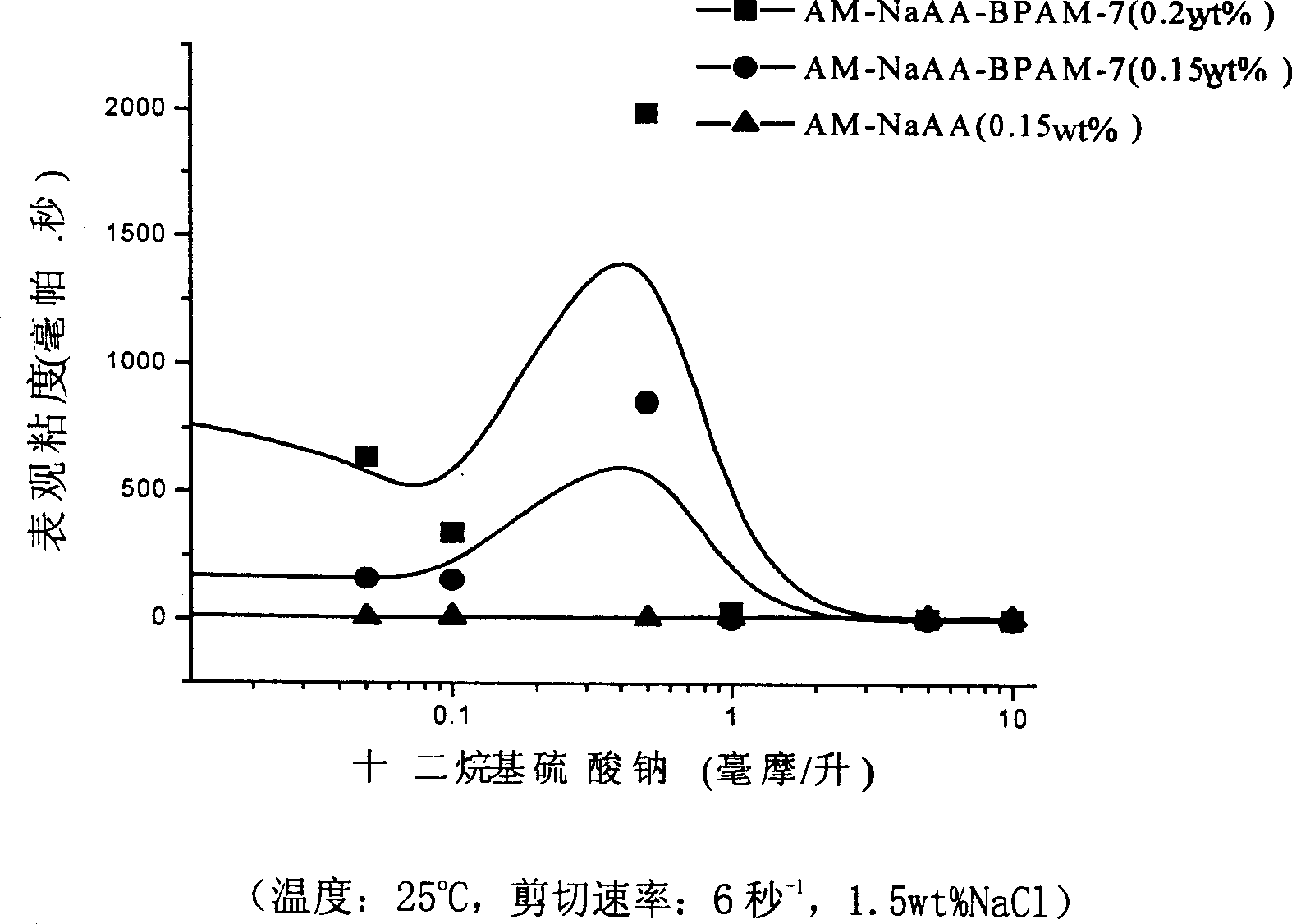

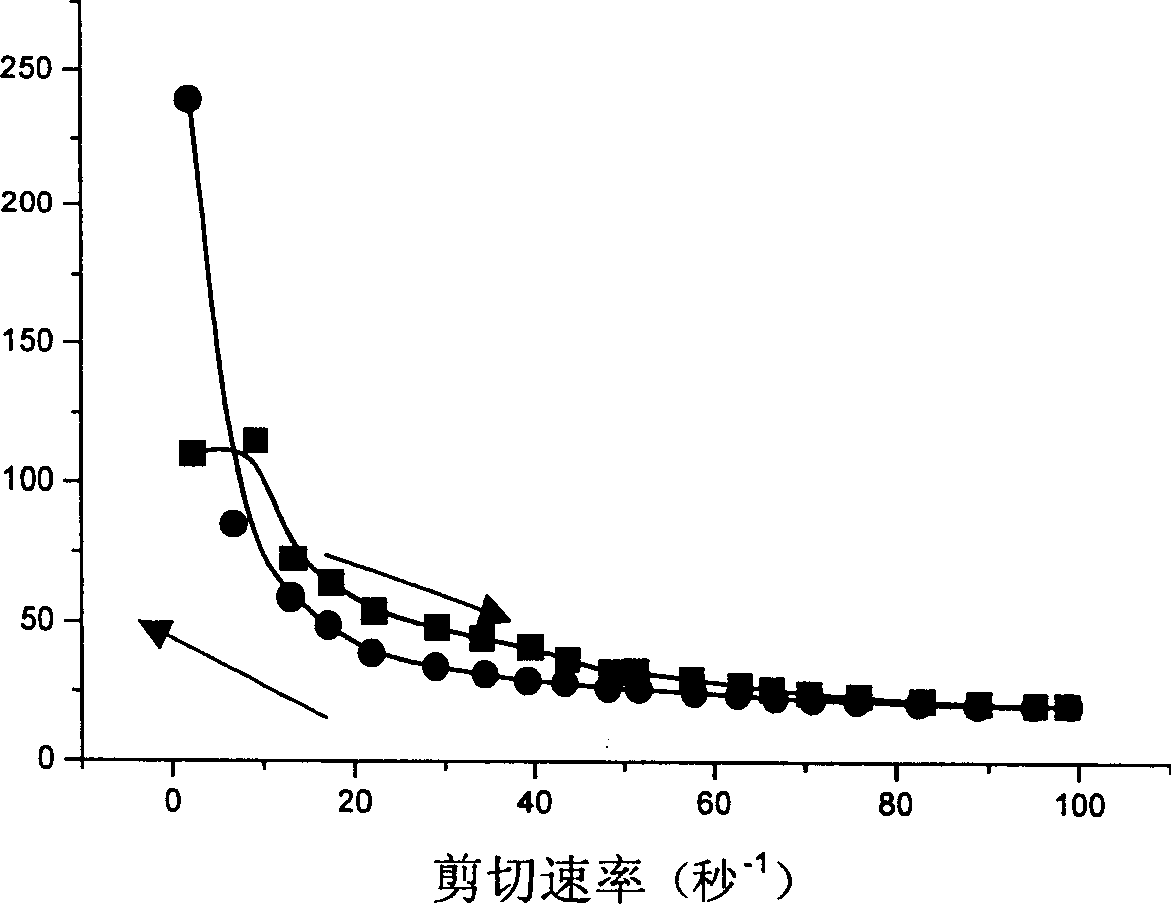

[0027] Dissolve 5.91 grams of acrylamide, 1.06 grams of sodium acrylate, 0.1 grams of N-p-butylphenylacrylamide and 10 grams of sodium lauryl sulfate in 81.3 milliliters of deionized water and add them to a three-necked bottle to adjust the pH of the solution to 9- 10. The temperature of the reaction system is 50°C, and N 2 Add 13.3 mg of potassium persulfate initiator after 30 minutes, and react for 12 hours. The polymer was diluted with water, then precipitated with acetone, washed, and dried in vacuum to obtain a white powdery AM-NaAA-BPAM polymer. A certain amount of polymer was taken to prepare an aqueous sample of an oil displacement agent, which was colorless and transparent. The polymer concentration is 0.15wt%, the sodium tetradecyl sulfate concentration is 0.5 mmol / liter, and the NaCl concentration is 1.5wt%, add it into a mixing tank with a stirrer and a thermometer, and stir evenly at a temperature of 25°C to obtain Highly viscous hydrophobic association water-sol...

Embodiment 2

[0029] Dissolve 6.6 grams of acrylamide, 3.5 grams of sodium acrylate, 0.1 grams of N-p-butylphenylacrylamide and 2.7 grams of sodium lauryl sulfate in 81.3 milliliters of deionized water, adjust the pH of the solution to 9-10, and the temperature of the reaction system at 50°C, through N 2Add 13.3 mg of potassium persulfate initiator after 30 minutes, and react for 12 hours. The polymer was diluted with water, then precipitated with acetone, washed, and dried in vacuum to obtain a white powdery AM-NaAA-BPAM polymer. A certain amount of polymer was taken to prepare an oil displacement agent aqueous solution sample, which was colorless and transparent, and the polymer concentration was 0.2wt%, cetyltrimethylammonium bromide concentration is 1 mmol / liter, and NaCl concentration is 1.5wt%, add in the mixing kettle with agitator and thermometer, stir evenly at temperature 30 ℃, obtain high Viscosified hydrophobically associated water-soluble polymer oil displacing agent.

Embodiment 3

[0031] Dissolve 4.16 grams of acrylamide, 2.91 grams of sodium acrylate, 0.1 grams of N-p-butylphenylacrylamide and 1.8 grams of sodium lauryl sulfate in 81.3 milliliters of deionized water, adjust the pH of the solution to 9-10, and the temperature of the reaction system at 50°C, through N 2 Add 13.3 mg of potassium persulfate initiator after 30 minutes, and react for 12 hours. The polymer product was diluted with water, then precipitated with acetone, washed, and vacuum-dried to obtain a white powdery AM-NaAA-BPAM polymer. A certain amount of polymer solution was taken to prepare an oil displacement agent aqueous solution sample. The polymer concentration was 0.1wt%. The concentration of dialkyl dimethyl ammonium oxide is 0.5 mmol / L, and the concentration of NaCl is 0.5 wt%. Add it into a mixing kettle with a stirrer and a thermometer, and stir evenly at a temperature of 35°C to obtain a highly viscosified hydrophobic association water-soluble Polymer oil displacing agent. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com