Freezing method and device for food

A freezing method and freezing device technology, which is applied in food preservation, meat/fish preservation through freezing/cooling, food science, etc. It can solve problems such as difficulty in establishing a magnetic field, freezing temperature difference, shape distortion, etc., so that the taste and color will not be reduced. , Excellent taste and color, good freshness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Put commercially available raw beef with a high fat content, cut into thickness 80mm, length and width 80mm each, into a polyethylene bag, and seal the bag by pumping out the air.

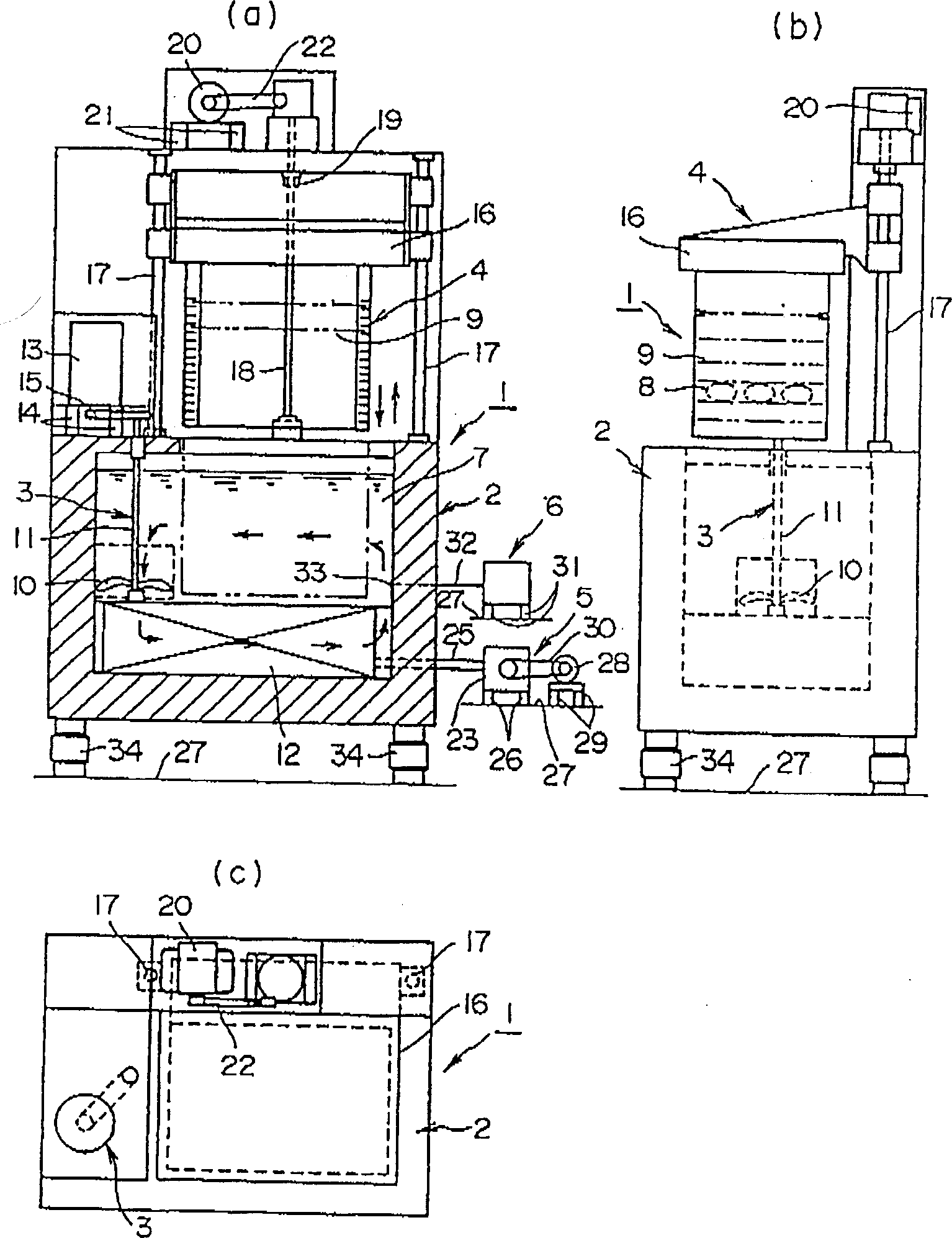

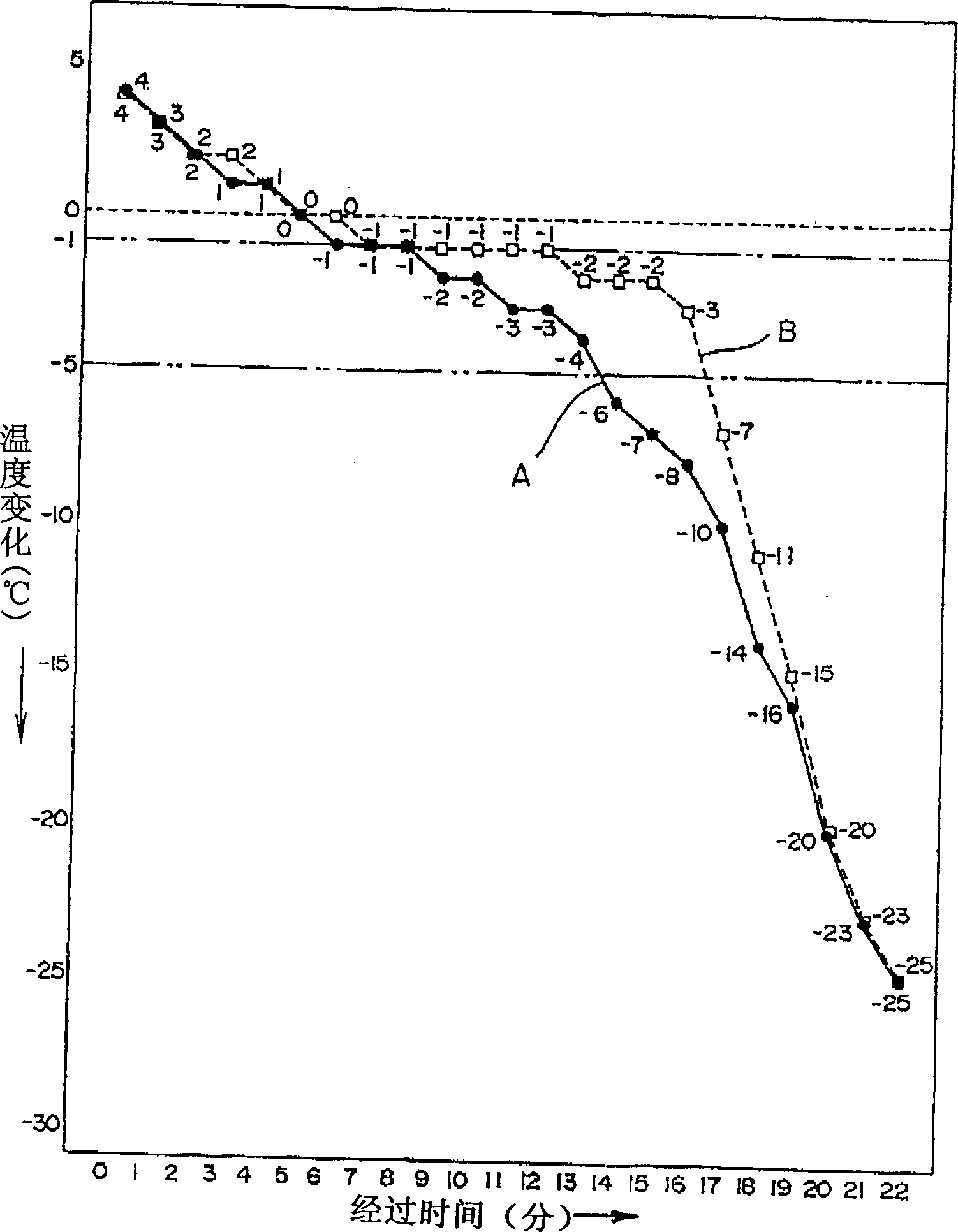

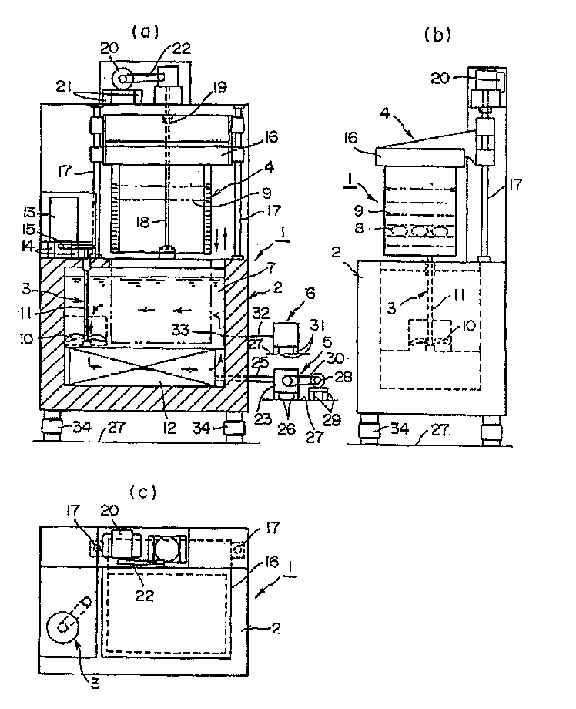

[0026] Freeze according to the method of the present invention. Antifreeze 7 uses 150 liters of 55% alcoholic aqueous solution, pre-cools to-35~-38 ℃, applies the electric potential of 10kv to this cooled antifreeze with high potential electric field generator 6, soaks above-mentioned beef. Use a temperature sensor to measure the temperature change process of the central part of the beef in soaking, and the result is shown in curve A figure 2 . In addition, in figure 2 Among them, as Comparative Example 1, without making the high-potential electric field generator 6 operate, that is, under the state of not applying an electric field, other conditions are the same, the same beef is frozen, and the temperature change process is measured, which is represented by curve B.

[0027] figure ...

Embodiment 2

[0029] The skin of the bamboo shoot dug up in the morning was peeled off, and the trunk part was put in a polyethylene bag in the same manner as above, and used as a sample. The sample frozen under the same conditions as in Example 1 by applying an electric field during freezing is designated as Example 2, and the sample frozen under the same conditions as in Comparative Example 1 without applying an electric field is designated as Comparative Example 2. A sample frozen in a general freezer was used as Comparative Example 3. After freezing, it stored in the same -30 degreeC freezer for 10 days, thawed with cold water, and evaluated the taste. The results are shown in Table 1. The numerical values in the table are usually the values obtained by summing up the evaluation scores of 8 judges, and the evaluation scores are 3 points for good, 2 points for fair, and 1 point for poor. The results in Table 1 show that the sample of Example 2 is good.

[0030] Example ...

Embodiment 3

[0032] Example 3

[0033] In addition, in particular, the amount of liquid dripped on the filter paper after each sample was thawed was studied as dripping liquid. In Example 3 and Comparative Example 4, it was hardly seen, but in Comparative Example 5, it was definitely seen. In addition, in terms of the freshness of food texture, Example 3 is considered to be the best, followed by Comparative Example 4, which is slightly inferior, and Comparative Example 5 is insufficient, and the order can be clearly ranked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com