Heat-insulating coating material and gas turbine component and gas turbine

A gas turbine and coating technology, which is applied in the direction of gas turbine devices, engine components, machines/engines, etc., can solve the problems of ceramic layer peeling and heat resistance damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

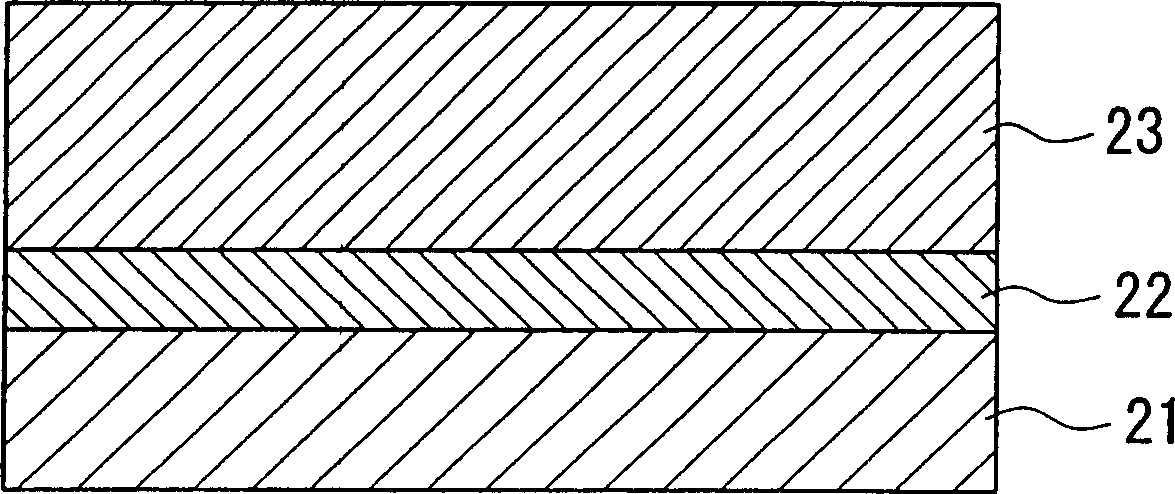

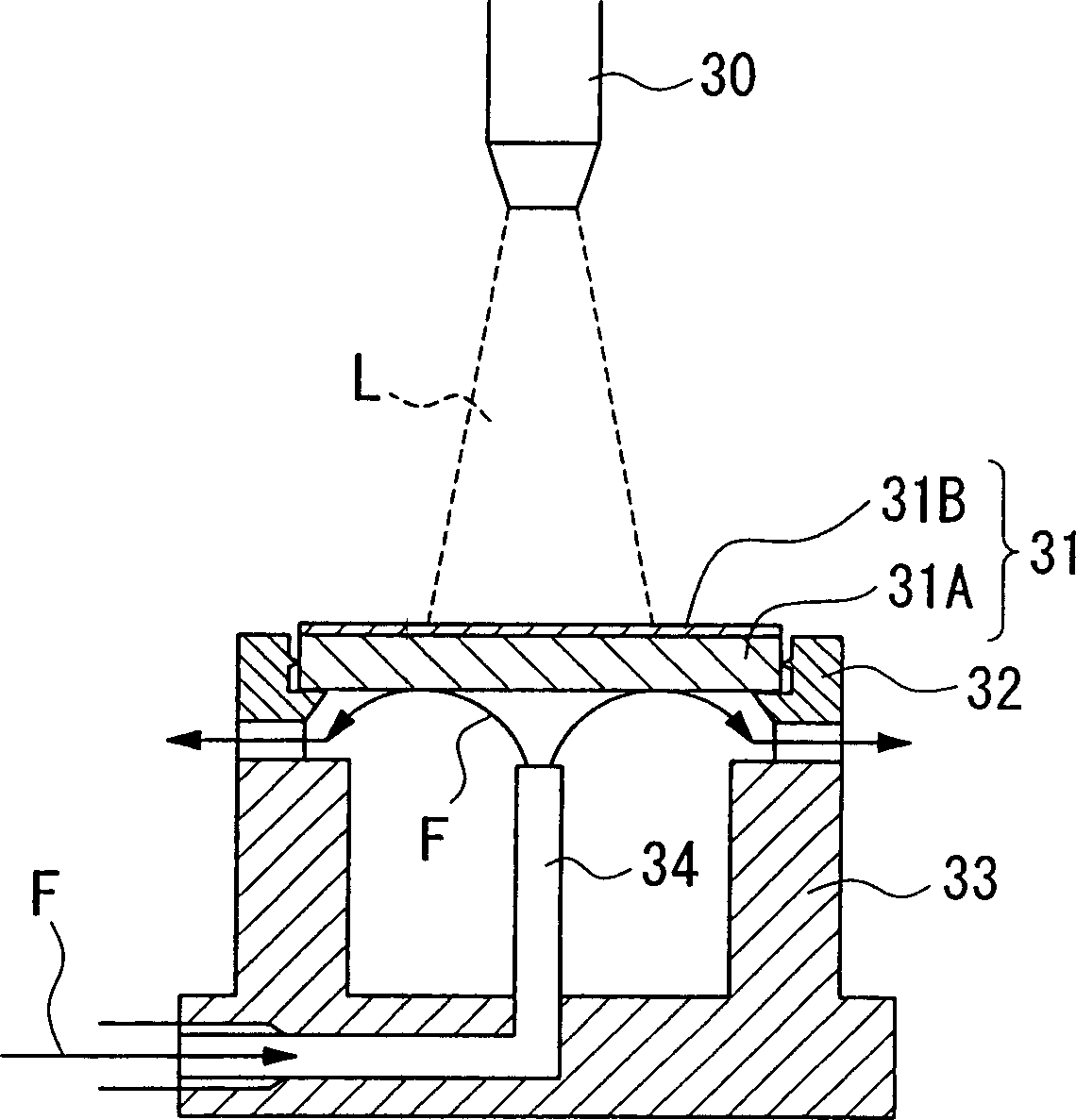

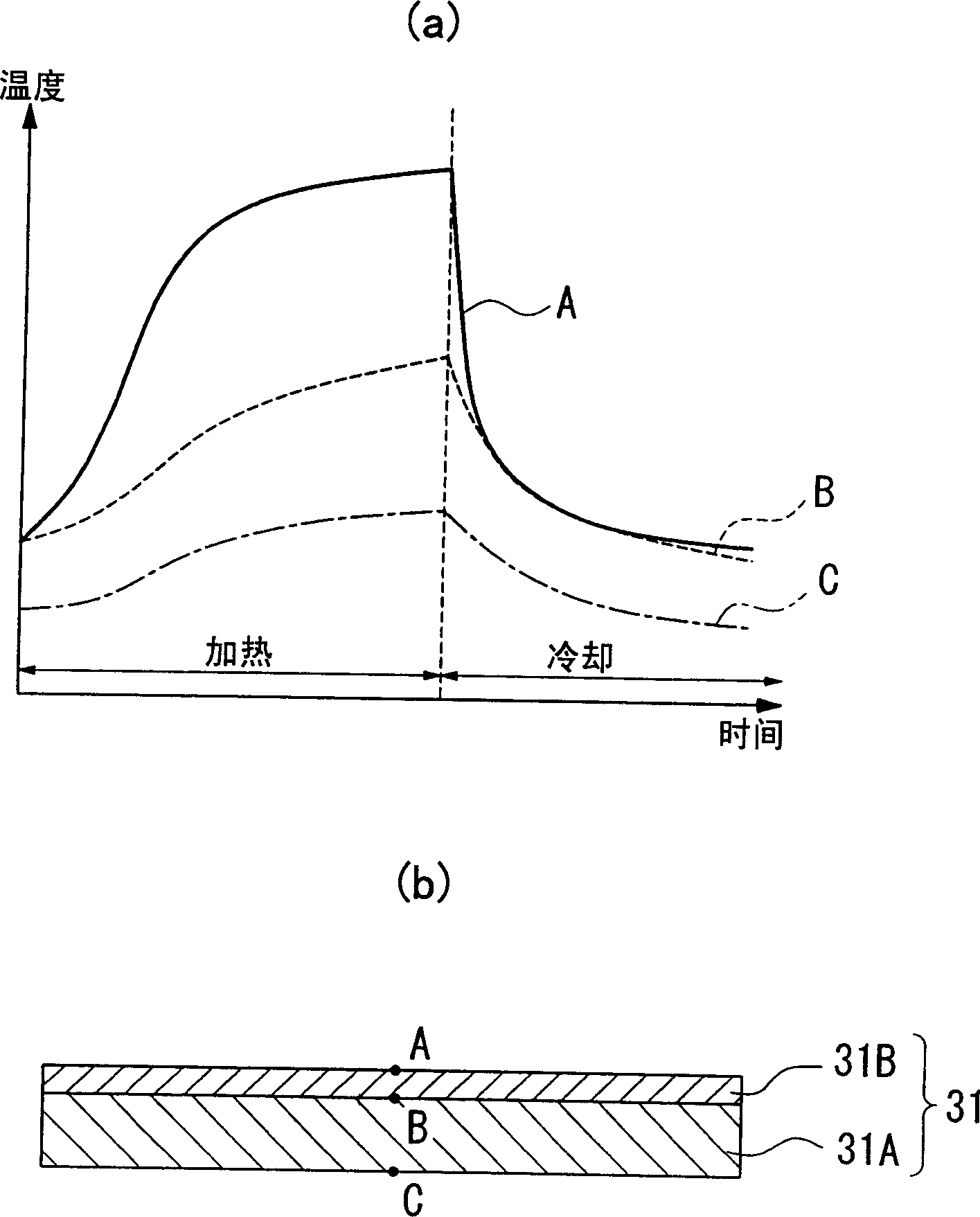

Embodiment 1

[0045] In this example, in order to verify that the thermal cycle life varies with Er 2 o 3 The change of the added amount forms a ZrO 2 Er in 2 o 3 The samples of the ErSZ layer in which the addition amount varied in various ways were used to measure the thermal cycle life. The matrix material used in the preparation of each sample is a Ni-based heat-resistant alloy, and its alloy composition is Ni-16Cr-8.5Co-1.7Mo-2.6W-1.7T-0.9Nb-3.4Al-3.4Ti. Al on the surface of the base material 2 o 3 After the grains are sand blasted, an adhesive layer composed of CoNiCrAlY alloy composed of Co-32Ni-21Cr-8Al-0.5Y is formed on it as a metal bonding layer by low-pressure plasma spraying method. In the adhesive layer of CoNiCrAlY On the top, the ceramic layer (ErSZ layer) is laminated by the atmospheric pressure plasma spraying method to form a heat-shielding coating film. Er in the ceramic layer of each sample 2 o 3 The amount added is shown in Table 1. (Sample Nos. 1 to 12).

[...

Embodiment 2

[0055] Next, in order to verify that the change in durability is due to the change in the porosity of ErSZ in the ceramic layer composed of ErSZ, a heat-insulating coating film with a ceramic layer having the porosity shown in Table 2 was formed on the base material. , Made various samples. The porosity of the ceramic layer of these samples can be obtained by adjusting the spraying current or the spraying distance in the spraying conditions to obtain a predetermined porosity. Moreover, in addition to the adjustment of the above-mentioned porosity and the use of Er 2 o 3 Except that the addition amount of the compound is 18% by weight, other conditions are the same as the above-mentioned examples, and each sample (No.15-23) is produced.

[0056] As shown in Table 2, it was confirmed that in the samples Nos. 18 to 20 with a porosity of the ceramic layer of 8 to 15%, the porosity of the ceramic layer shown in Table 1 was higher than that of the conventional ceramic layer compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com